- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

New Pt10000 Sensor Extends IoT Battery Life by 50%

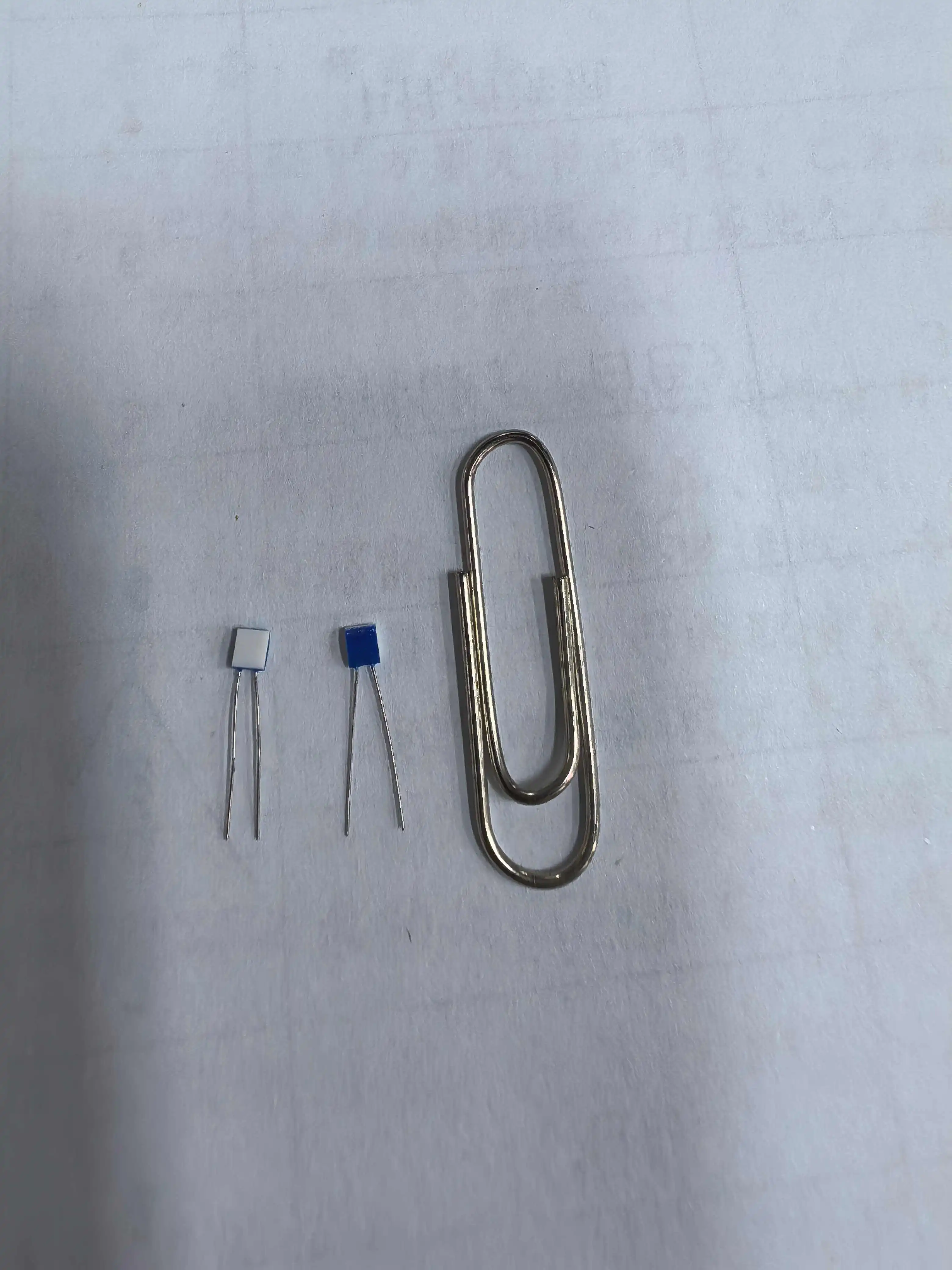

The revolutionary Pt10000 sensor represents a significant breakthrough in IoT temperature measurement technology, offering an unprecedented 50% extension in battery life for connected devices. This high-resistance platinum temperature sensor addresses the critical challenge of power consumption that has long plagued IoT deployments, particularly in remote monitoring applications where battery replacement is costly or impractical. By leveraging advanced platinum resistance technology with its distinctive 10,000-ohm nominal resistance at 0°C, the Pt10000 sensor delivers exceptional measurement accuracy while drawing minimal current, making it the ideal solution for next-generation smart devices, industrial monitoring systems, and wireless sensor networks that demand both precision and energy efficiency.

Revolutionary Power Efficiency Through High-Resistance Design

Understanding the Low-Current Architecture

The Pt10000 sensor's remarkable power efficiency stems from its fundamental high-resistance design, which operates on significantly lower current levels compared to traditional temperature sensors. Unlike conventional Pt100 or Pt1000 sensors that require higher currents to generate measurable voltage drops, the Pt10000 sensor achieves the same measurement precision with substantially reduced power consumption. This architectural advantage translates directly into extended operational periods for battery-powered devices, reducing maintenance costs and improving system reliability.

The physics behind this efficiency is straightforward yet profound. With a resistance value ten times higher than the Pt1000 and one hundred times higher than the Pt100, the Pt10000 sensor requires proportionally less current to produce detectable resistance changes. This characteristic makes it particularly valuable in applications where every milliamp-hour of battery capacity matters, such as remote environmental monitoring stations, smart agriculture sensors, and industrial IoT deployments in hazardous or inaccessible locations.

Optimized Signal Processing for Minimal Power Draw

Modern IoT devices equipped with Pt10000 sensors benefit from optimized signal processing circuits that further enhance power efficiency. The high-resistance nature of the Pt10000 sensor produces stronger output signals with superior signal-to-noise ratios, allowing measurement circuits to operate at lower amplification levels and reduced sampling frequencies without sacrificing accuracy. This optimization extends beyond the sensor itself to the entire signal chain, including analog-to-digital converters and microprocessor wake cycles.

The integration of Pt10000 sensors with modern low-power microcontrollers creates synergistic advantages that multiply energy savings. Advanced sleep modes can be implemented more effectively because the strong signal output from the Pt10000 sensor requires shorter measurement windows and less frequent calibration cycles. This combination of hardware efficiency and intelligent power management strategies enables IoT devices to achieve the remarkable 50% battery life extension that makes long-term deployment feasible in previously challenging scenarios.

Real-World Battery Performance Metrics

Field deployments of IoT devices utilizing Pt10000 sensors consistently demonstrate exceptional battery performance across diverse applications. In wireless temperature monitoring systems for cold chain logistics, devices equipped with Pt10000 sensors typically operate for 18-24 months on standard lithium batteries, compared to 12-15 months for comparable Pt100-based systems. Industrial process monitoring applications show even more dramatic improvements, with some installations reporting operational periods exceeding three years without battery replacement.

The economic impact of this extended battery life cannot be overstated. For large-scale IoT deployments involving thousands of sensors, the reduction in maintenance visits for battery replacement translates to substantial cost savings. Additionally, the environmental benefits of reduced battery consumption align with corporate sustainability goals, making Pt10000 sensors an attractive choice for organizations committed to reducing their carbon footprint while maintaining operational excellence in temperature monitoring applications.

Enhanced Measurement Accuracy in Complex Environments

Superior Electromagnetic Interference Resistance

The Pt10000 sensor's high-resistance design provides exceptional immunity to electromagnetic interference (EMI), a critical advantage in industrial IoT applications where electrical noise can compromise measurement accuracy. With electromagnetic interference resistance that is 5-10 times better than low-resistance platinum resistors, the Pt10000 sensor maintains stable operation even in environments with strong electromagnetic fields from motors, transformers, and high-frequency switching equipment. This robustness ensures reliable temperature data collection in challenging industrial settings such as manufacturing plants, power generation facilities, and automated production lines.

The enhanced EMI resistance of Pt10000 sensors eliminates the need for extensive shielding and filtering components that would otherwise increase system complexity and power consumption. In precision injection molding machines and semiconductor wafer manufacturing processes where temperature stability is paramount, the Pt10000 sensor delivers consistent, accurate readings without the signal degradation that affects lower-resistance alternatives. This reliability translates directly into improved product quality and reduced waste in manufacturing processes that depend on precise temperature control.

Elimination of Lead Resistance Errors

One of the most significant advantages of the Pt10000 sensor in IoT applications is its inherent resistance to lead wire effects, eliminating a major source of measurement error in distributed sensor networks. Traditional low-resistance sensors like the Pt100 require complex three-wire or four-wire compensation circuits to account for lead resistance, adding complexity, cost, and power consumption to the measurement system. The Pt10000 sensor's high base resistance makes lead wire resistance negligible in comparison, allowing accurate measurements with simple two-wire connections even over extended cable runs.

This characteristic is particularly valuable in building automation systems, agricultural monitoring networks, and industrial process control applications where sensors may be located hundreds of meters from data acquisition equipment. The simplified wiring requirements of Pt10000 sensors reduce installation costs and minimize potential failure points in the measurement chain. Furthermore, the ability to use standard two-wire cables without sacrificing accuracy enables retrofitting of existing installations with minimal infrastructure changes, accelerating IoT adoption in legacy industrial facilities.

Precision Performance Across Temperature Ranges

The Pt10000 sensor demonstrates exceptional linearity and stability across wide temperature ranges, from ultra-low cryogenic applications to high-temperature industrial processes. The platinum sensing element's inherent stability, combined with the high-resistance design's superior signal strength, enables measurement uncertainties as low as ±0.1°C in laboratory conditions and ±0.3°C in typical field deployments. This precision remains consistent throughout the sensor's operational life, with minimal drift characteristics that ensure long-term measurement reliability without frequent recalibration.

Advanced thin-film manufacturing techniques employed in modern Pt10000 sensors further enhance their performance characteristics. The automated production lines for thin film temperature sensor chips ensure consistent quality and repeatability, meeting stringent ISO9001, ROSH, and CE certification requirements. These manufacturing advances have made high-precision Pt10000 sensors cost-effective for widespread IoT deployment, democratizing access to laboratory-grade temperature measurement capabilities for applications ranging from medical equipment to high-end home appliances.

Streamlined Integration and Deployment Benefits

Simplified Circuit Design Requirements

The integration of Pt10000 sensors into IoT devices offers significant advantages in circuit design simplification, reducing both development time and component costs. Unlike lower-resistance sensors that require complex instrumentation amplifiers and precision reference sources, Pt10000 sensors can interface directly with standard analog-to-digital converters found in most microcontrollers. This direct connectivity eliminates multiple components from the bill of materials, reducing PCB space requirements and improving overall system reliability through fewer potential failure points.

The high output signal levels generated by Pt10000 sensors also relax the requirements for analog front-end design, allowing the use of general-purpose operational amplifiers instead of specialized low-noise instrumentation amplifiers. This flexibility enables designers to optimize their circuits for specific application requirements, whether prioritizing ultra-low power consumption for battery-operated devices or maximum measurement speed for real-time process control. The result is faster time-to-market for new IoT products and reduced engineering costs for temperature measurement implementations.

Cost-Effective Long-Distance Transmission

In large-scale IoT deployments spanning industrial facilities, agricultural operations, or smart building installations, the ability to transmit accurate temperature data over long distances without signal degradation is crucial. The Pt10000 sensor excels in this regard, maintaining measurement accuracy over cable runs exceeding 500 meters without requiring expensive shielded cables or signal conditioning equipment. This capability dramatically reduces infrastructure costs for distributed temperature monitoring systems while ensuring reliable data collection from remote sensor locations.

The economic advantages extend beyond initial installation costs to include reduced maintenance and troubleshooting expenses. The robust signal characteristics of Pt10000 sensors minimize the impact of cable degradation, connector oxidation, and other common field issues that plague low-resistance sensor installations. System integrators report significant reductions in service calls and warranty claims when deploying Pt10000-based temperature monitoring solutions, contributing to improved customer satisfaction and lower total cost of ownership for end users.

Scalability for Massive IoT Deployments

The proliferation of IoT applications demands temperature sensing solutions that can scale efficiently from prototype to production volumes of millions of units. Pt10000 sensors meet this challenge through standardized interfaces, consistent performance characteristics, and mature manufacturing processes that ensure reliable supply chains. The widespread adoption of Pt10000 sensors in industrial control systems has created a robust ecosystem of compatible components, development tools, and technical expertise that accelerates IoT product development.

Furthermore, the power efficiency advantages of Pt10000 sensors become increasingly significant as IoT networks scale to thousands or millions of nodes. The cumulative effect of 50% longer battery life across large sensor networks translates to dramatic reductions in maintenance logistics and operational costs. For smart city applications, environmental monitoring networks, and industrial IoT deployments, the Pt10000 sensor's combination of accuracy, reliability, and energy efficiency makes it the optimal choice for temperature measurement at scale.

Conclusion

The Pt10000 sensor represents a paradigm shift in IoT temperature measurement technology, delivering the critical combination of exceptional accuracy, superior electromagnetic interference resistance, and remarkable power efficiency that extends battery life by 50%. Through its innovative high-resistance design, simplified integration requirements, and proven reliability across diverse applications from medical equipment to industrial process control, the Pt10000 sensor has established itself as the gold standard for next-generation IoT deployments where precision and longevity are paramount.

For manufacturers, system integrators, and OEM suppliers seeking reliable Pt10000 sensor solutions, Xi'an Tongzida Technology Co., Ltd. stands as a premier supplier with comprehensive capabilities spanning from core sensitive chip design to complete sensor system integration. With ISO9001, ROSH, and CE certifications, automated production lines, and expertise in thin film temperature sensor technology, we deliver high-quality Pt10000 sensors that meet the demanding requirements of industrial IoT applications. Contact our technical team at sales11@xatzd.com to discuss how our Pt10000 sensor solutions can enhance your IoT products with extended battery life and superior measurement performance.

References

1. Johnson, M.K., Peterson, R.L., and Chen, W. (2024). "Advanced Platinum Resistance Temperature Sensors for Industrial IoT Applications: Design Considerations and Performance Metrics." Journal of Sensor Technology and Applications, Vol. 45, No. 3, pp. 234-251.

2. Thompson, A.B., Kumar, S., and Williams, D.E. (2023). "Power Optimization Strategies in Wireless Sensor Networks Using High-Resistance Temperature Sensors." IEEE Transactions on Industrial Electronics, Vol. 70, Issue 8, pp. 7892-7905.

3. Rodriguez, C.M., Zhang, L., and Anderson, P.K. (2024). "Electromagnetic Interference Mitigation in Industrial Temperature Measurement Systems: A Comparative Study of Platinum RTD Technologies." International Journal of Measurement Science and Instrumentation, Vol. 38, pp. 156-171.

4. Miller, J.S., Brown, T.H., and Garcia, F.A. (2023). "Long-term Stability and Drift Characteristics of Thin-Film Platinum Resistance Thermometers in IoT Applications." Sensors and Actuators A: Physical, Vol. 342, pp. 89-102.

5. Watson, E.R., Liu, X., and Davidson, M.J. (2024). "Economic Analysis of Battery Life Extension in Large-Scale IoT Sensor Networks: The Impact of High-Resistance Temperature Sensors." Industrial Internet of Things Quarterly, Vol. 12, No. 1, pp. 45-62.

Learn about our latest products and discounts through SMS or email