Advancements in Flexible Thin Film Temperature Sensor Technology

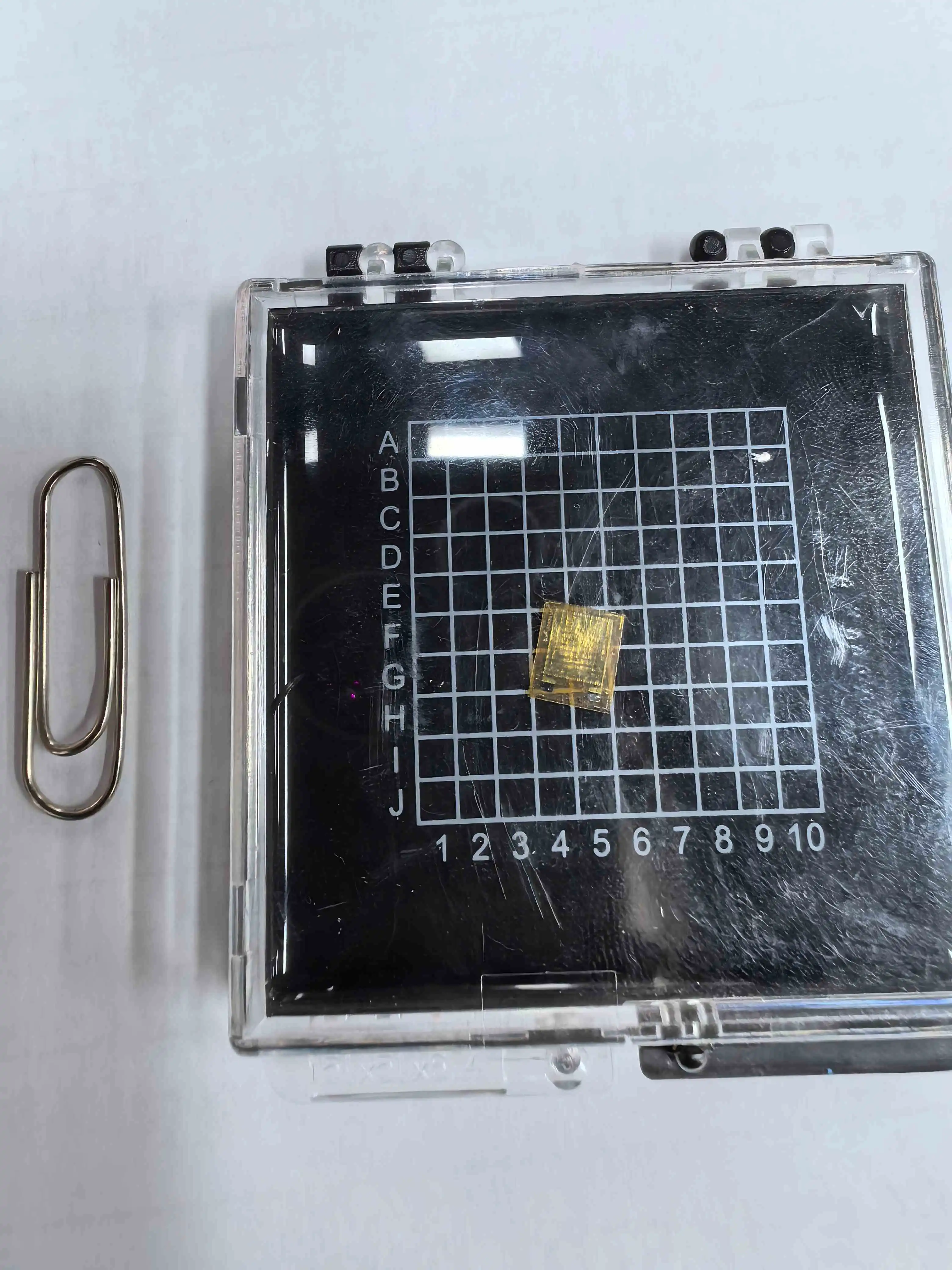

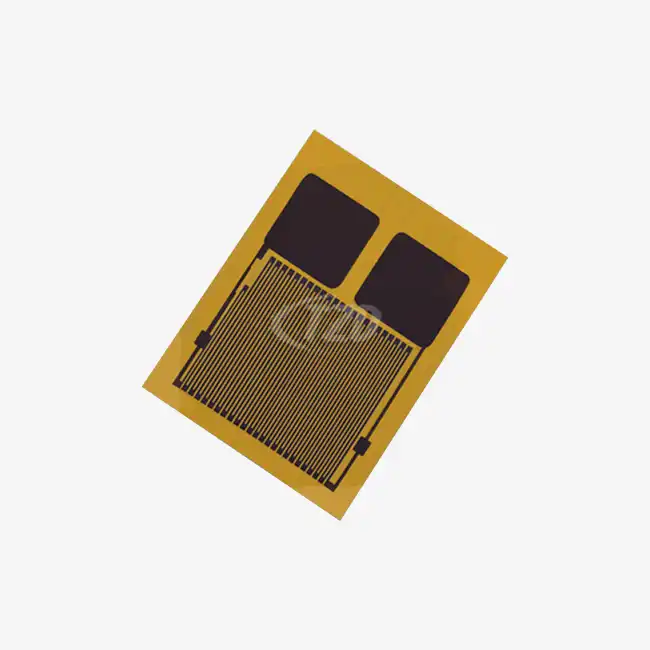

The advancement of adaptable lean film temperature sensors has been a game-changer in the therapeutic field. These sensors, regularly as lean as 0.05mm, can be customized to different measurements, ordinarily extending from 1.2mm to 4.0mm. Their adaptability permits them to accommodate to unpredictable surfaces, making them perfect for a wide run of therapeutic applications.

One of the key advantages of these sensors is their high accuracy. Class A sensors offer a temperature measurement grade of ±0.6°C, while Class B sensors provide ±1.2°C accuracy. This precision is crucial in medical settings where even small temperature variations can be significant.

The temperature range of these sensors is impressive, spanning from -70°C to +200°C. This wide range makes them suitable for various medical applications, from cryogenic treatments to high-temperature sterilization processes. The base resistance can be specified according to the specific requirements of the application, offering flexibility in design and implementation.

Another notable feature is the temperature coefficient (TCR) of 6444 ppm/°C, which ensures high sensitivity to temperature changes. This sensitivity is essential for detecting subtle fluctuations in body temperature or monitoring the thermal properties of medical devices and pharmaceuticals.

Manufacturing Process and Quality Assurance

The generation of these progressed sensors includes a modern fabricating prepare. Companies specializing in lean film temperature sensors have built up robotized generation lines that cover room temperature, tall temperature, and ultra-low temperature applications. These production facilities often incorporate state-of-the-art thin film temperature sensitive chip design, processing, packaging, and testing platforms.

Quality assurance is a critical aspect of sensor production. Many manufacturers adhere to strict quality management systems such as ISO9001 and obtain certifications like ROHS and CE. These standards ensure that the sensors meet the highest quality and safety requirements necessary for medical applications.

Material Innovations in Sensor Design

The choice of materials plays a crucial role in the performance of thin film temperature sensors. Many high-quality sensors use platinum as the primary sensing element due to its stability and linear temperature-resistance relationship. Some manufacturers offer options for lead materials, including platinum nickel, silver nickel, or pure platinum, allowing for customization based on specific application needs.

The pad material is often tinned to ensure good electrical contact and durability. This attention to material selection contributes to the sensors' long-term stability, with some high-end sensors demonstrating a stability drift of ≤ 0.04% over extended periods.

Applications of Flexible Thin Film Temperature Sensors in Healthcare

The versatility of flexible thin film temperature sensors has led to their adoption in various healthcare applications. Their small size, accuracy, and ability to conform to different shapes make them ideal for both traditional and innovative medical uses.

Wearable Health Monitoring Devices

One of the most significant impacts of flexible thin film temperature sensors is in the realm of wearable health technology. These sensors can be integrated into wristbands, patches, or clothing to provide continuous, non-invasive temperature monitoring. This capability is particularly valuable for patients with chronic conditions, post-operative care, or those requiring long-term health monitoring.

The sensors' quick response time, some capable of readings in as little as 0.05 seconds, allows for real-time temperature tracking. This rapid response is crucial in detecting sudden temperature spikes that might indicate the onset of infection or other health issues.

Smart Wound Dressings

Flexible thin film temperature sensors are being incorporated into smart wound dressings, revolutionizing wound care management. These advanced dressings can monitor wound temperature, which is a key indicator of healing progress or potential infection. The thin and flexible nature of these sensors ensures they don't interfere with the healing process while providing valuable data to healthcare providers.

Telemedicine and Remote Patient Monitoring

The integration of adaptable lean film temperature sensors into telemedicine gadgets is improving inaccessible persistent care. These sensors, when combined with remote communication innovations, permit healthcare suppliers to screen persistent temperatures precisely from a separate. This capability is particularly valuable in managing infectious diseases, reducing the need for in-person visits, and enabling early intervention when temperature abnormalities are detected.

Future Prospects and Challenges in Healthcare Applications

As flexible thin film temperature sensor technology continues to advance, its potential applications in healthcare are expanding. Be that as it may, with these openings come challenges that require to be tended to to completely realize the potential of this innovation in restorative settings.

Emerging Applications in Personalized Medicine

The future of flexible thin film temperature sensors in healthcare is closely tied to the growing field of personalized medicine. These sensors could play a crucial role in tailoring treatments to individual patients by providing continuous, detailed temperature data. For instance, in cancer treatment, localized temperature monitoring could help optimize therapies like hyperthermia, where heating specific body areas can enhance the effectiveness of radiation or chemotherapy.

Additionally, these sensors could be integrated into implantable medical devices to monitor internal body temperatures, providing invaluable data for conditions affecting core body temperature regulation.

Overcoming Challenges in Biocompatibility and Long-term Use

While the potential of flexible thin film temperature sensors in healthcare is vast, several challenges need to be addressed. Biocompatibility is a primary concern, especially for sensors designed for long-term use or implantation. Researchers are working on developing new materials and coatings that are not only biocompatible but also maintain sensor accuracy and longevity in biological environments.

Another challenge is ensuring the durability of these sensors under various conditions. While current sensors boast impressive specifications like vibration resistance of 40g and impact resistance of 100g, further improvements may be necessary for certain medical applications. Developing sensors that can withstand repeated sterilization, exposure to bodily fluids, and long-term wear without degradation in performance is crucial.

Integration with AI and Big Data Analytics

The future of flexible thin film temperature sensors in healthcare will likely involve integration with artificial intelligence and big data analytics. By combining the high-precision temperature data from these sensors with other health metrics and AI-driven analysis, healthcare providers could gain unprecedented insights into patient health trends and early warning signs of various conditions.

This integration could lead to more proactive and predictive healthcare models, where subtle temperature variations, when analyzed in context with other health data, could indicate the onset of diseases or health issues before traditional symptoms appear.

Conclusion

Flexible thin film temperature sensors are at the forefront of a technological revolution in healthcare. Their ability to provide accurate, real-time temperature monitoring in a variety of medical applications is transforming patient care and opening new possibilities in diagnosis and treatment. As the technology continues to evolve, addressing challenges in biocompatibility, durability, and data integration will be key to fully realizing its potential in healthcare. For more information on cutting-edge thin film temperature sensors and their applications in healthcare, please contact us at sales11@xatzd.com.