Understanding Pt100 Temperature Sensors: Principles and Advantages

The Science Behind Pt100 Sensors

Pt100 Temperature Sensors operate on the principle of resistance temperature detectors (RTDs). The "Pt" in Pt100 stands for platinum, while "100" indicates that the sensor has a resistance of 100 ohms at 0°C. This platinum element exhibits a predictable change in electrical resistance as temperature fluctuates, allowing for precise temperature measurements.

The relationship between temperature and resistance in Pt100 sensors is nearly linear, following the Callendar-Van Dusen equation. This linearity contributes to their high accuracy across a wide temperature range. Modern Pt100 sensors, like those manufactured by Xi'an Tongzida Technology Co., Ltd., utilize thin-film technology, offering improved response times and durability.

Key Advantages of Pt100 Sensors in Industrial Applications

Pt100 Temperature Sensors offer several advantages that make them ideal for industrial use:

- High Accuracy: With an accuracy of ±0.01 Ω, Pt100 sensors provide exceptionally precise temperature measurements critical for many industrial processes.

- Wide Temperature Range: Capable of measuring temperatures from -200°C to +850°C, these sensors are versatile enough for various industrial environments.

- Excellent Stability: Pt100 sensors exhibit minimal drift over time, with long-term stability drift ≤0.04%, ensuring reliable measurements over extended periods.

- Vibration and Shock Resistance: With vibration resistance up to 40g and impact resistance of 100g, these sensors are suitable for harsh industrial environments.

- Fast Response Time: Advanced Pt100 sensors can achieve response times as low as 0.05 seconds, crucial for real-time process control.

These characteristics make Pt100 Temperature Sensors invaluable in industries requiring precise temperature control and monitoring.

Industrial Applications of Pt100 Temperature Sensors

Process Control and Manufacturing

In process control and manufacturing, Pt100 Temperature Sensors play a crucial role in maintaining optimal conditions for various operations. Their high accuracy and stability are particularly beneficial in:

- Chemical Processing: Precise temperature control is essential in chemical reactions, distillation processes, and storage of temperature-sensitive materials.

- Metallurgy: Pt100 sensors monitor and control temperatures in smelting, annealing, and heat treatment processes, ensuring product quality and consistency.

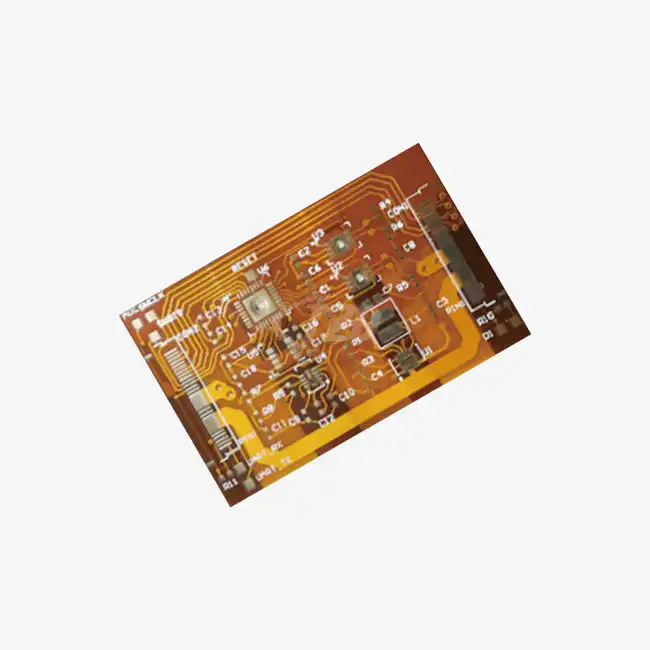

- Semiconductor Manufacturing: These sensors provide the accuracy needed for precise temperature control in wafer production and other semiconductor processes.

The wide temperature range of Pt100 sensors (-200°C to +850°C) makes them versatile for various manufacturing processes, from cryogenic applications to high-temperature operations.

Food and Beverage Industry

In the food and beverage industry, temperature control is critical for safety, quality, and compliance with regulations. Pt100 Temperature Sensors are extensively used in:

- Food Processing: Monitoring cooking, pasteurization, and sterilization processes to ensure food safety and quality.

- Cold Chain Management: Maintaining proper temperatures during transportation and storage of perishable goods.

- Beverage Production: Controlling fermentation temperatures in brewing and winemaking processes.

The sensors' high accuracy (±0.01 Ω) and long-term stability (drift ≤0.04%) are particularly valuable in these applications, where even small temperature deviations can significantly impact product quality and safety.

Pharmaceutical and Biotechnology Industries

In pharmaceutical and biotechnology industries, where precision and reliability are paramount, Pt100 Temperature Sensors are indispensable. They are used in:

- Drug Manufacturing: Ensuring precise temperature control during the production of pharmaceuticals.

- Biotech Research: Maintaining optimal conditions for cell cultures and biological experiments.

- Vaccine Storage: Monitoring ultra-low temperature freezers for vaccine preservation.

The sensors' fast response time (as low as 0.05 seconds) and high stability make them ideal for these critical applications, where temperature fluctuations can have significant consequences.

Technological Advancements and Future Trends in Pt100 Sensors

Miniaturization and Improved Performance

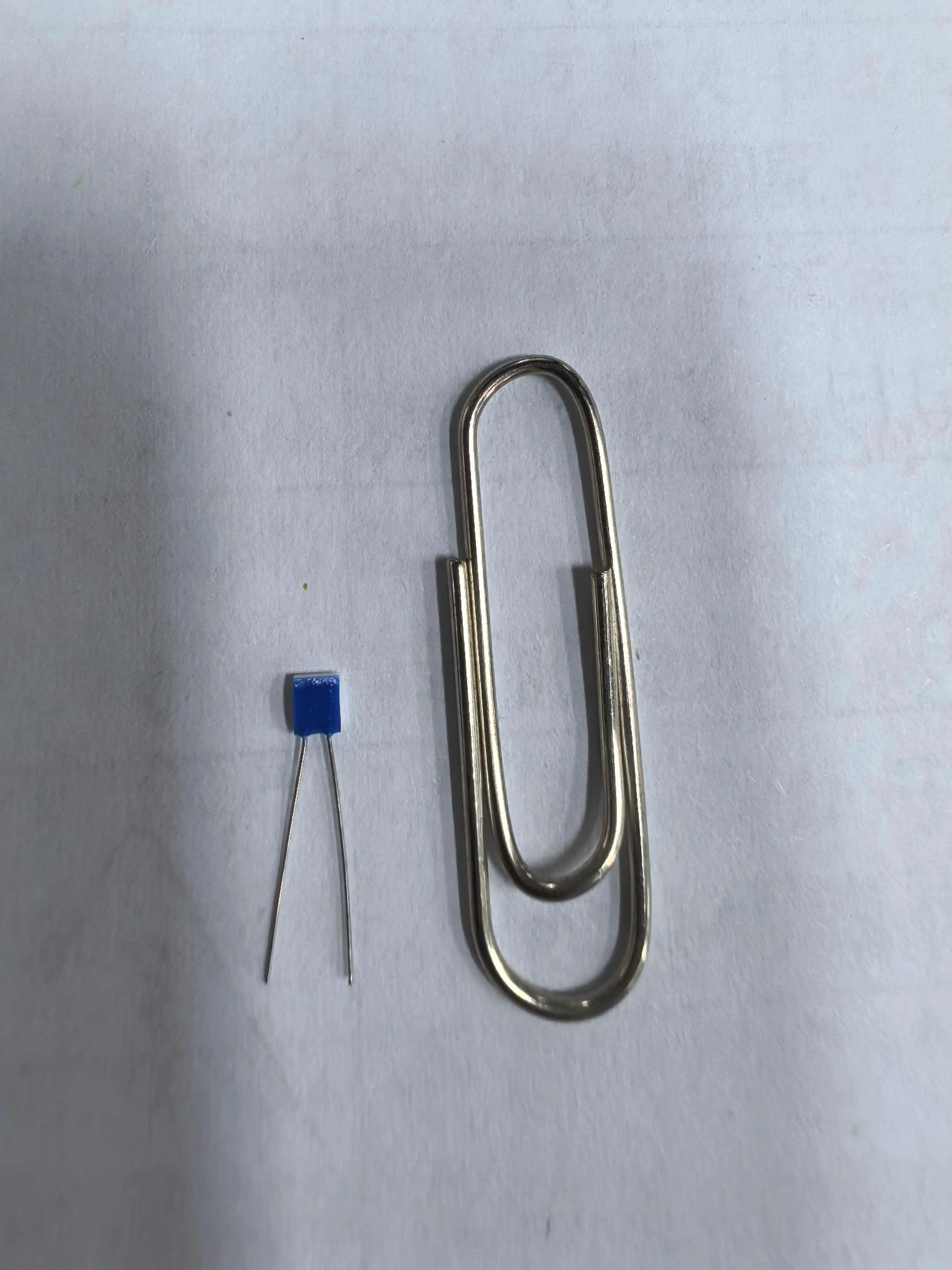

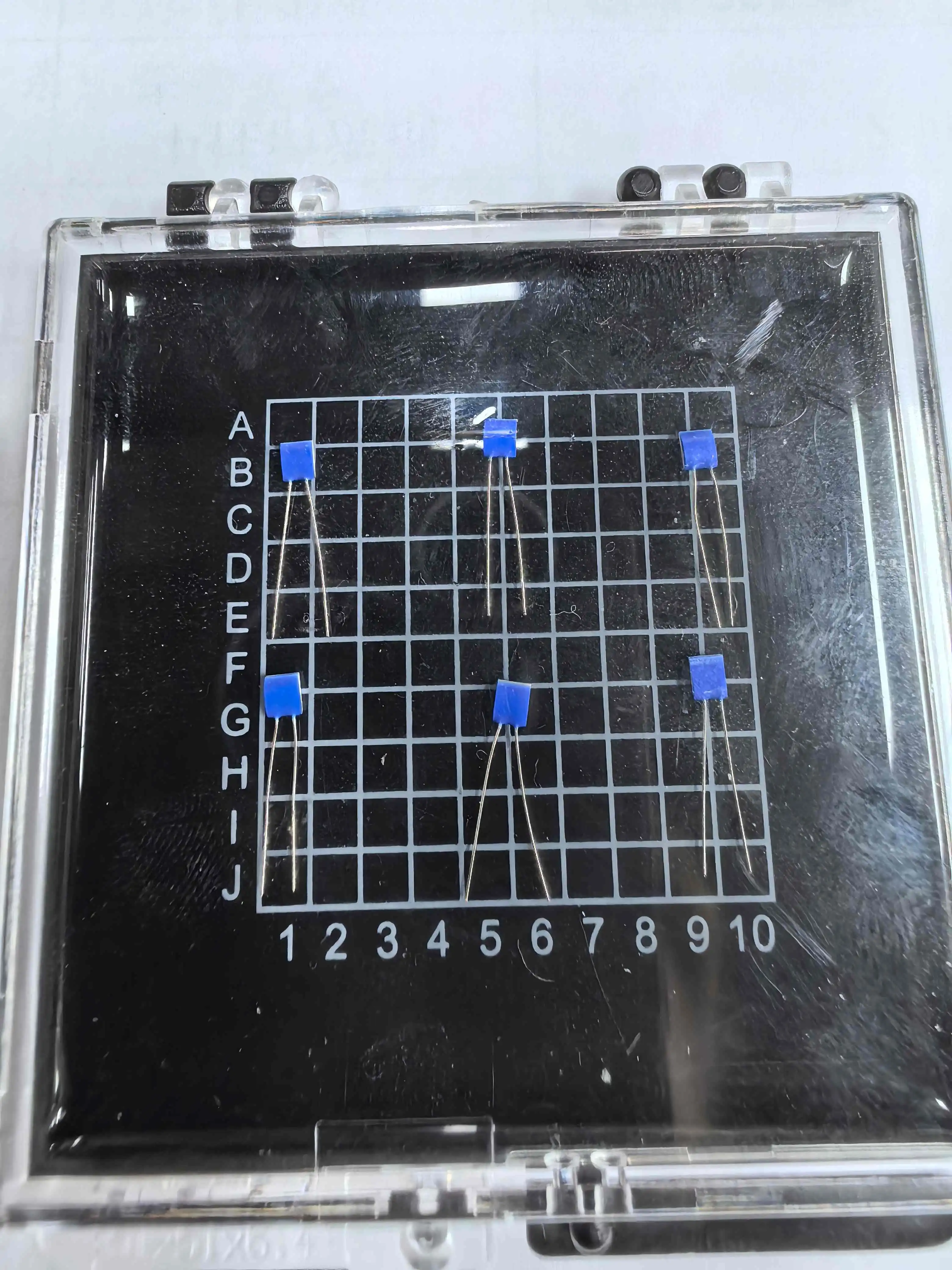

Recent advancements in Pt100 Temperature Sensor technology have focused on miniaturization and improved performance. Companies like Xi'an Tongzida Technology Co., Ltd. are at the forefront of these developments, offering sensors with dimensions as small as 1.2mm to 4.0mm. This miniaturization allows for more precise measurements in confined spaces and enables the integration of temperature sensing in smaller devices.

Furthermore, advancements in thin-film technology have led to Pt100 sensors with enhanced characteristics:

- Improved Temperature Coefficient: Modern sensors achieve a temperature coefficient of 3850ppm/°C, enhancing measurement accuracy.

- Enhanced Stability: Long-term stability has improved, with some sensors showing ≤±0.06% resistance drift of R₀°C after 1000 hours at 200°C.

- Wider Temperature Range: Some advanced Pt100 sensors can now operate effectively from -50°C to +200°C in a single package.

Integration with IoT and Industry 4.0

The future of Pt100 Temperature Sensors lies in their integration with Internet of Things (IoT) and Industry 4.0 technologies. This integration is paving the way for:

- Real-time Monitoring: Continuous temperature data collection and analysis for improved process control and predictive maintenance.

- Smart Manufacturing: Integration with AI and machine learning algorithms for optimized production processes.

- Remote Sensing: Ability to monitor and control temperatures in remote or hazardous environments.

These advancements are making Pt100 sensors more versatile and valuable in industrial applications, contributing to increased efficiency and reduced operational costs.

Customization and Specialized Applications

As industrial needs become more specialized, there's a growing trend towards customized Pt100 Temperature Sensors. Manufacturers are offering:

- Customized Sizes: Tailored sensor dimensions to fit specific application requirements.

- Specialized Lead Materials: Options for platinum nickel, silver nickel, or pure platinum leads to suit different environmental conditions.

- Application-Specific Designs: Sensors optimized for particular industries or processes, such as aerospace or automotive applications.

This trend towards customization ensures that Pt100 sensors can meet the evolving needs of diverse industrial applications, further cementing their position as a critical component in temperature measurement and control systems.

Conclusion

Pt100 Temperature Sensors have proven to be indispensable in a wide array of industrial applications, from process control and food production to pharmaceutical manufacturing and beyond. Their high accuracy, stability, and versatility make them a preferred choice for industries requiring precise temperature measurement and control. As technology continues to advance, we can expect to see even more innovative applications and improvements in Pt100 sensor technology, further enhancing their utility in industrial settings.

For more information about cutting-edge Pt100 Temperature Sensors and their industrial applications, please contact Xi'an Tongzida Technology Co., Ltd. at sales11@xatzd.com. Our team of experts is ready to assist you in finding the perfect temperature sensing solution for your specific industrial needs.