- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Understanding RTD, Thermistor, and Thermocouple Applications

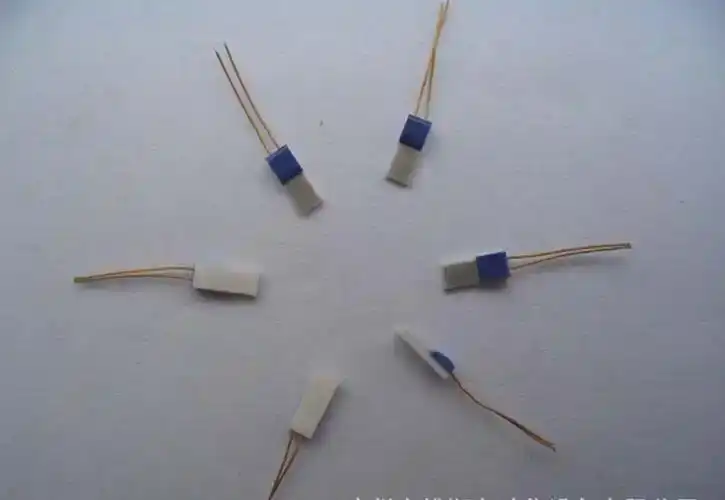

Mastering the application-specific characteristics of RTD, thermistor, and thermocouple technologies is essential for engineers and procurement professionals selecting optimal temperature measurement solutions for diverse industrial, scientific, and commercial applications. Each temperature sensor technology offers unique advantages and limitations that make them suitable for specific operating conditions, accuracy requirements, and environmental challenges encountered in modern measurement systems. Professional temperature sensor selection requires comprehensive understanding of performance characteristics, installation requirements, and cost considerations that determine the most suitable technology for particular applications.

RTD Temperature Sensor Applications and Performance Characteristics

Industrial Process Control and Manufacturing Applications

RTD temperature sensors excel in industrial process control applications where precise temperature regulation ensures product quality, safety compliance, and operational efficiency across manufacturing processes. Professional manufacturing operations utilize RTD sensors in chemical reactors, pharmaceutical synthesis equipment, and food processing systems where temperature accuracy directly impacts product specifications and regulatory compliance. The superior accuracy and long-term stability of RTD temperature sensors make them indispensable for critical control points in semiconductor fabrication, precision injection molding, and materials processing where small temperature variations significantly affect product quality and production yield.

Advanced manufacturing processes increasingly rely on RTD temperature sensor networks that provide comprehensive temperature monitoring throughout production facilities, enabling automated control systems to maintain optimal conditions while generating detailed documentation required for quality assurance and regulatory validation. Modern high-resistance RTD designs offer enhanced performance characteristics including improved signal-to-noise ratios and electromagnetic interference resistance that ensure reliable operation in electrically noisy industrial environments.

Laboratory and Scientific Research Applications

Scientific research and calibration laboratories depend on RTD temperature sensors for precision measurements requiring the highest accuracy and traceability to international temperature standards for experimental validation and measurement certification. Professional laboratory RTD temperature sensor systems enable researchers to collect accurate temperature data for materials characterization, environmental studies, and fundamental research where measurement uncertainty must be minimized to ensure valid scientific conclusions.

Metrology laboratories utilize RTD temperature sensors as working standards for calibrating other measurement devices due to their predictable performance characteristics and excellent long-term stability compared to alternative sensor technologies. Advanced laboratory RTD systems incorporate precision signal conditioning and automated data acquisition capabilities that support standardized testing procedures while maintaining measurement traceability required for accredited calibration services. The temperature sensor technology provides the accuracy foundation for scientific research and industrial calibration activities that support quality management systems and regulatory compliance across diverse technical fields requiring precise temperature measurement capabilities.

Medical Equipment and Healthcare Applications

Medical device applications require RTD temperature sensors for critical temperature monitoring in patient care equipment, diagnostic instruments, and pharmaceutical storage systems where accuracy and reliability directly impact patient safety and treatment effectiveness. Professional medical equipment utilizes RTD sensors in incubators, sterilization systems, and laboratory analyzers where precise temperature control ensures optimal performance and regulatory compliance with healthcare standards.

Healthcare facility environmental control systems rely on RTD temperature sensors for maintaining precise conditions required for sensitive medical procedures, pharmaceutical storage, and laboratory testing where temperature variations could compromise product efficacy or test results. Advanced medical RTD sensor systems incorporate features such as drift monitoring, self-diagnostics, and data logging capabilities that support quality assurance programs and regulatory documentation requirements in healthcare environments. The temperature sensor technology provides the measurement reliability required for critical healthcare applications where sensor failures could create safety hazards or compromise patient care quality in demanding medical environments.

Thermistor Temperature Sensor Applications and Design Considerations

HVAC and Building Automation Systems

Thermistor temperature sensors provide cost-effective temperature measurement solutions for building automation and HVAC applications where high sensitivity and fast response characteristics optimize energy efficiency and occupant comfort across diverse climate control systems. Professional building automation systems utilize thermistor sensors in zone control applications, air handling units, and energy management systems where accurate temperature feedback enables efficient heating and cooling operations while minimizing operational costs. The high sensitivity of thermistor temperature sensors enables detection of small temperature variations that support sophisticated control algorithms providing optimal indoor environmental conditions while reducing energy consumption.

Modern building automation applications benefit from thermistor temperature sensor networks that provide comprehensive environmental monitoring throughout facilities, enabling centralized control systems to optimize HVAC performance while maintaining comfortable conditions for occupants. Advanced thermistor designs incorporate digital communication capabilities and self-calibration features that simplify system integration while providing diagnostic information supporting predictive maintenance programs.

Automotive and Transportation Temperature Control

Automotive applications extensively utilize thermistor temperature sensors for engine management, climate control, and thermal protection systems where fast response characteristics and compact packaging enable integration into space-constrained vehicle systems. Professional automotive thermistor sensors provide temperature feedback for engine control units that optimize fuel efficiency, emissions control, and performance while preventing thermal damage to critical components. The rugged construction and reliable performance of automotive thermistor temperature sensors ensure accurate measurements in harsh operating environments with vibration, temperature extremes, and chemical exposure throughout vehicle operational life.

Electric and hybrid vehicle applications increasingly depend on thermistor temperature sensors for battery thermal management, power electronics cooling, and regenerative braking systems where precise temperature monitoring ensures optimal performance and component longevity. Advanced automotive thermistor systems incorporate features such as fault detection, self-diagnostics, and communication interfaces that support sophisticated vehicle control strategies while providing data for predictive maintenance programs. The temperature sensor technology enables efficient thermal management that extends component life while optimizing energy efficiency in modern vehicle systems where thermal control directly impacts performance and operational costs.

Consumer Electronics and Appliance Applications

Consumer electronics manufacturers utilize thermistor temperature sensors for thermal protection, performance optimization, and energy efficiency in devices ranging from smartphones and computers to home appliances and industrial equipment. Professional electronics applications require thermistor sensors that provide accurate temperature feedback for thermal management systems preventing overheating damage while maintaining optimal performance characteristics. The compact size and cost-effectiveness of thermistor temperature sensors make them ideal for mass-produced consumer products where temperature monitoring improves reliability and user experience while meeting regulatory safety requirements.

Home appliance applications benefit from thermistor temperature sensor integration in refrigerators, ovens, water heaters, and HVAC systems where precise temperature control enhances performance while reducing energy consumption and operational costs. Modern smart appliance designs incorporate thermistor sensors with digital interfaces that enable remote monitoring and control capabilities while providing diagnostic information supporting maintenance and energy optimization programs. The temperature sensor technology provides reliable temperature measurement in demanding consumer applications where long-term performance and cost-effectiveness determine product success in competitive markets.

Thermocouple Temperature Sensor Applications and Environmental Considerations

High-Temperature Industrial Process Monitoring

Thermocouple temperature sensors excel in high-temperature industrial applications including furnace monitoring, metal processing, and power generation systems where extreme operating conditions exceed the capabilities of RTD and thermistor technologies. Professional high-temperature applications utilize specialized thermocouple types that maintain measurement accuracy and mechanical integrity in environments exceeding 1000°C where other temperature sensor technologies would fail completely. The robust construction and wide temperature range capabilities of thermocouple sensors make them essential for steel production, glass manufacturing, and ceramic processing where continuous temperature monitoring ensures process control and product quality.

Industrial furnace applications require thermocouple temperature sensors capable of withstanding thermal cycling, chemical attack, and mechanical stress while providing reliable temperature feedback for automated control systems. Advanced thermocouple installations incorporate protective systems and specialized materials that extend sensor life while maintaining measurement accuracy in demanding high-temperature environments. The temperature sensor technology enables process optimization and energy efficiency improvements in energy-intensive industries where accurate temperature measurement directly impacts production costs and environmental compliance requirements.

Aerospace and Defense Applications

Aerospace applications demand thermocouple temperature sensors for jet engine monitoring, spacecraft thermal management, and missile guidance systems where reliable operation under extreme conditions ensures mission success and personnel safety. Professional aerospace thermocouple sensors must withstand temperature extremes, vibration, shock, and radiation exposure while providing accurate temperature measurements for critical flight systems and propulsion control. The proven reliability and performance characteristics of thermocouple temperature sensors make them essential for applications where sensor failures could result in catastrophic consequences or mission failures.

Military and defense applications utilize ruggedized thermocouple sensors for equipment thermal monitoring, weapons systems temperature control, and environmental testing where reliable performance under harsh conditions ensures operational readiness and system effectiveness. Advanced military thermocouple systems incorporate features such as electromagnetic pulse resistance, secure communication interfaces, and enhanced durability that meet stringent military specifications and security requirements. The temperature sensor technology provides the measurement reliability required for critical defense applications where sensor performance directly impacts national security and military operational capabilities.

Power Generation and Energy Systems

Power generation facilities rely on thermocouple temperature sensors for turbine monitoring, boiler control, and exhaust gas temperature measurement where high-temperature capability and long-term reliability ensure safe and efficient energy production. Professional power plant applications utilize thermocouple sensors in steam generators, gas turbines, and nuclear reactor systems where continuous temperature monitoring supports automated control systems and safety protection functions. The wide temperature range and robust construction of thermocouple temperature sensors make them indispensable for energy production applications where measurement failures could create safety hazards or expensive equipment damage.

Renewable energy applications increasingly utilize thermocouple sensors for solar thermal systems, geothermal installations, and biomass combustion control where temperature monitoring optimizes energy conversion efficiency while ensuring safe operation. Advanced power generation thermocouple systems incorporate digital communication capabilities and predictive maintenance features that support plant optimization and maintenance planning programs. The temperature sensor technology enables efficient energy production and environmental compliance in modern power systems where accurate temperature measurement directly impacts operational efficiency and regulatory compliance requirements.

Conclusion

Understanding RTD, thermistor, and thermocouple applications requires comprehensive analysis of performance characteristics, operating requirements, and cost considerations that determine optimal temperature sensor selection for specific measurement needs. Each technology offers unique advantages: RTDs for precision applications, thermistors for cost-effective high-sensitivity measurements, and thermocouples for extreme temperature environments, enabling engineers to select appropriate solutions that maximize measurement system performance while meeting application-specific requirements.

Xi'an Tongzida Technology Co., Ltd. stands as a premier temperature sensor manufacturer and supplier, leveraging advanced microsensor manufacturing technology and specialized packaging expertise to deliver comprehensive temperature measurement solutions across RTD, thermistor, and thermocouple technologies. Our extensive capabilities encompass thin film temperature sensor design, automated production lines, and rigorous quality control systems backed by ISO9001, ROHS, and CE certifications. As experienced temperature sensor suppliers serving diverse industrial markets, we provide technical excellence and application expertise to optimize measurement system performance. Contact our engineering team at sales11@xatzd.com for expert guidance on temperature sensor selection and application requirements.

References

1. Bentley, R.E. (2021). Handbook of Temperature Measurement: RTD, Thermistor, and Thermocouple Applications. Springer International Publishing, 4th Edition.

2. McGee, T.D. (2020). Industrial Temperature Sensor Applications: Comparative Analysis and Selection Guide. John Wiley & Sons, Industrial Instrumentation Series.

3. Nicholas, J.V. & White, D.R. (2019). Temperature Measurement Technologies: Applications and Performance Comparison. John Wiley & Sons, Measurement Science Series.

4. Webster, J.G. & Eren, H. (2021). The Measurement, Instrumentation and Sensors Handbook: Temperature Sensor Application Guide. CRC Press, 3rd Edition.

5. Wilson, J.S. (2020). Sensor Technology Handbook: Temperature Measurement Applications in Industry. Newnes, Industrial Electronics Ser

Learn about our latest products and discounts through SMS or email