Comprehending High Current Thermal Resistor Temperature Sensors

High current thermal resistor temperature sensors, also known as thermistors, are specialized components designed to measure temperature changes in electrical circuits. These sensors leverage the principle of temperature-dependent resistance to detect variations in current flow. As current passes through the sensor, it generates heat, causing the resistance to change proportionally. This unique characteristic allows the sensor to accurately monitor and respond to overcurrent situations.

The effectiveness of these sensors lies in their ability to provide rapid and precise temperature measurements. With response times as quick as 0.05 seconds, they can detect sudden spikes in current almost instantaneously. This swift reaction is crucial in preventing damage to sensitive electronic components and ensuring the overall safety of the system.

Types of Thermal Resistor Sensors

There are two primary types of thermal resistor sensors used in overcurrent protection:

1. Negative Temperature Coefficient (NTC) Thermistors: These sensors exhibit a decrease in resistance as temperature increases. NTC thermistors are widely used due to their high sensitivity and fast response times.

2. Positive Temperature Coefficient (PTC) Thermistors: In contrast to NTC thermistors, PTC sensors show an increase in resistance with rising temperatures. They are particularly useful in self-regulating heating applications and overcurrent protection circuits.

Both types of sensors have their unique advantages and are selected based on specific application requirements. The choice between NTC and PTC thermistors depends on factors such as the desired temperature range, sensitivity, and circuit design considerations.

Key Features of High Current Thermal Resistor Temperature Sensors

Modern high current thermal resistor temperature sensors boast impressive specifications that make them ideal for overcurrent protection applications. Some key features include:

- Temperature Coefficient (TCR): Typically around 3850 ppm/°C, ensuring high sensitivity to temperature changes.

- Wide Temperature Range: Capable of operating from -200°C to +850°C, suitable for diverse environments.

- High Accuracy: Precision of ±0.01 Ω, allowing for reliable current monitoring.

- Excellent Stability: Long-term stability drift ≤ 0.04%, ensuring consistent performance over time.

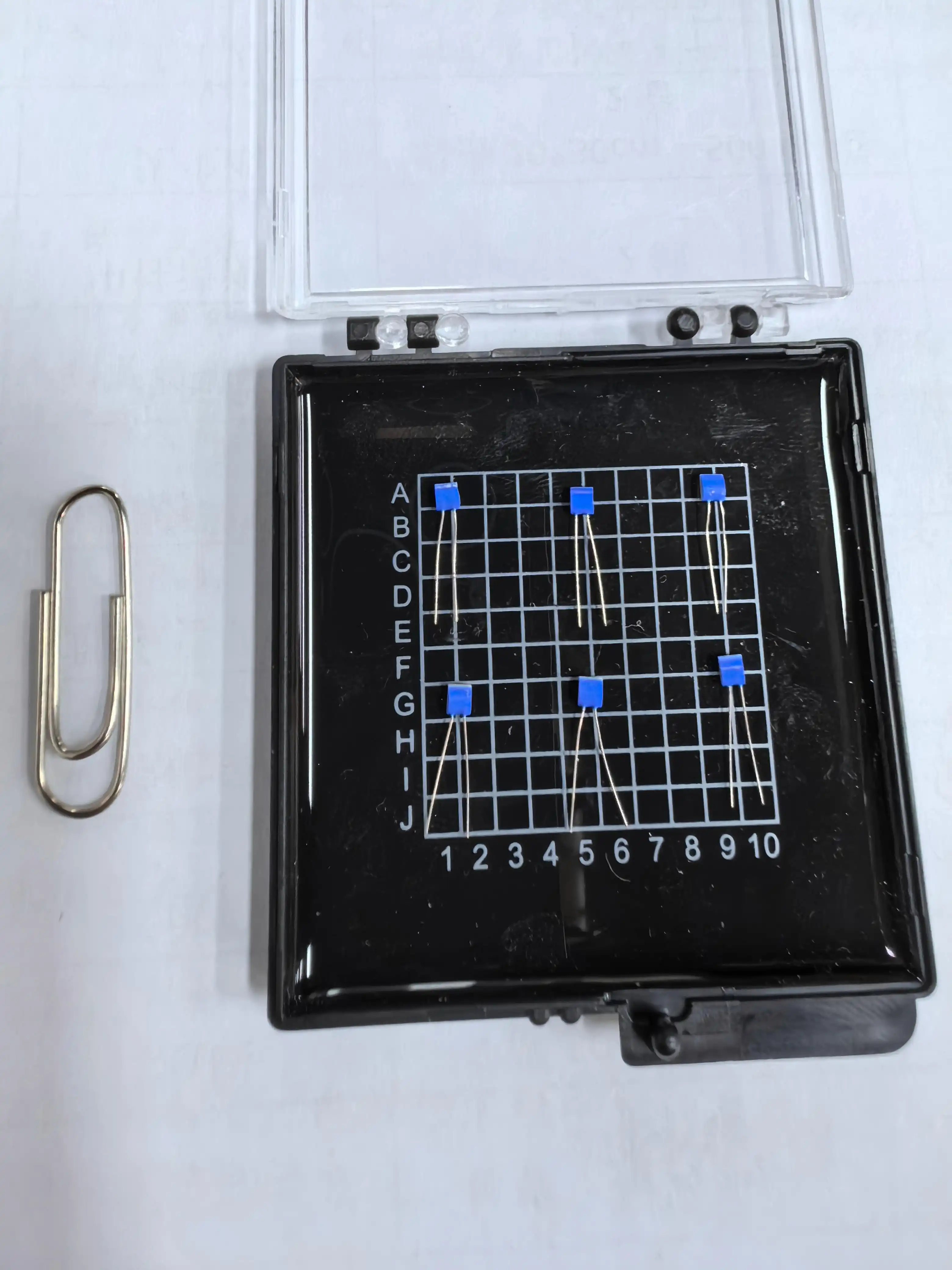

- Compact Size: Available in dimensions as small as 1.2mm x 2.0mm x 1.0mm, facilitating integration into compact designs.

- Robust Construction: Vibration resistance of 40g and impact resistance of 100g, suitable for harsh industrial environments.

These advanced features enable high current thermal resistor temperature sensors to provide reliable overcurrent protection across a wide range of applications, from industrial machinery to sensitive medical equipment.

Implementing Overcurrent Protection with Thermal Resistor Sensors

Integrating high current thermal resistor temperature sensors into overcurrent protection systems requires careful consideration of various factors. The implementation process involves selecting the appropriate sensor type, designing the circuit, and calibrating the system for optimal performance.

Sensor Selection and Placement

Choosing the right thermal resistor sensor is crucial for effective overcurrent protection. Factors to consider include:

- Current Rating: Select a sensor capable of handling the maximum expected current in the circuit.

- Temperature Range: Ensure the sensor's operating range matches the expected temperature conditions.

- Response Time: Opt for sensors with rapid response times to detect sudden current spikes.

- Size and Form Factor: Consider space constraints and choose a sensor that fits the application.

Proper placement of the sensor within the circuit is equally important. Ideally, the sensor should be positioned close to potential heat sources or areas prone to overcurrent conditions. This strategic placement ensures quick detection of temperature changes associated with excessive current flow.

Circuit Design Considerations

Designing an effective overcurrent protection circuit using thermal resistor sensors involves several key considerations:

1. Voltage Divider Configuration: Implement a voltage divider circuit to measure the resistance changes of the thermal resistor sensor accurately.

2. Amplification: Use operational amplifiers to amplify the small voltage changes produced by the sensor, improving sensitivity and accuracy.

3. Comparator Circuit: Incorporate a comparator to set a threshold voltage that triggers protective actions when exceeded.

4. Microcontroller Integration: Consider using a microcontroller for more advanced monitoring and control capabilities, allowing for programmable thresholds and data logging.

By carefully designing these circuit elements, engineers can create a robust overcurrent protection system that responds swiftly and accurately to potential threats.

Calibration and Testing

Proper calibration of the thermal resistor sensor and associated circuitry is essential for reliable overcurrent protection. The calibration process typically involves:

1. Characterizing the sensor's resistance-temperature relationship across its operating range.

2. Adjusting amplifier gains and comparator thresholds to match the specific application requirements.

3. Conducting thorough testing under various current conditions to verify the system's response.

4. Fine-tuning the circuit to eliminate false triggers while ensuring prompt activation during genuine overcurrent events.

Regular testing and recalibration may be necessary to maintain the system's accuracy and reliability over time, especially in applications subject to environmental variations or aging effects.

Applications and Benefits of Thermal Resistor-Based Overcurrent Protection

High current thermal resistor temperature sensors find applications in a wide range of industries and devices, offering numerous benefits in overcurrent protection scenarios.

Industrial Applications

In industrial settings, thermal resistor sensors play a critical role in protecting valuable equipment and ensuring workplace safety. Some key applications include:

- Motor Protection: Safeguarding electric motors from overheating due to excessive current draw.

- Power Distribution Systems: Monitoring current levels in switchgear and distribution panels to prevent overloads.

- Industrial Machinery: Protecting sensitive components in manufacturing equipment from current-induced damage.

- Process Control: Ensuring the safe operation of heating elements and other current-driven processes.

The robust construction and wide temperature range of these sensors make them ideal for harsh industrial environments, where reliability is paramount.

Automotive Applications

The automotive industry extensively uses thermal resistor sensors for overcurrent protection in various systems:

- Battery Management: Monitoring charging and discharging currents to prevent battery damage.

- Electric Vehicle Powertrains: Protecting high-power electronic components in electric and hybrid vehicles.

- Lighting Systems: Safeguarding LED and other advanced lighting technologies from current spikes.

- Engine Control Units: Ensuring the integrity of critical engine management systems.

The compact size and high accuracy of these sensors make them particularly suitable for the space-constrained and demanding automotive environment.

Consumer Electronics

In the realm of consumer electronics, thermal resistor-based overcurrent protection is essential for device safety and longevity:

- Smartphones and Tablets: Protecting battery charging circuits and power management systems.

- Laptop Computers: Safeguarding sensitive components from power fluctuations and overloads.

- Home Appliances: Ensuring the safe operation of high-current devices like washing machines and refrigerators.

- Audio Equipment: Protecting speakers and amplifiers from damaging current levels.

The fast response times and high sensitivity of these sensors contribute to the overall reliability and safety of consumer electronic devices.

Benefits of Thermal Resistor-Based Overcurrent Protection

Implementing overcurrent protection using high current thermal resistor temperature sensors offers several advantages:

- Precise Current Monitoring: Accurate detection of overcurrent conditions across a wide range of applications.

- Fast Response Times: Rapid triggering of protective measures to prevent damage to sensitive components.

- Versatility: Suitable for various current levels and environmental conditions.

- Cost-Effective: Relatively inexpensive compared to other overcurrent protection technologies.

- Compact Size: Easy integration into space-constrained designs.

- Low Power Consumption: Minimal impact on overall system efficiency.

- Reliability: Consistent performance over extended periods, with minimal drift or degradation.

These benefits make thermal resistor sensors an attractive choice for engineers seeking effective and efficient overcurrent protection solutions.

Conclusion

High current thermal resistor temperature sensors have revolutionized overcurrent protection across various industries. Their ability to provide accurate, rapid, and reliable current monitoring makes them an indispensable component in modern electrical systems. From industrial machinery to consumer electronics, these sensors play a crucial role in safeguarding equipment, enhancing safety, and preventing costly failures.

As technology continues to advance, we can expect further improvements in thermal resistor sensor technology, leading to even more precise and efficient overcurrent protection solutions. Engineers and manufacturers looking to implement these sensors in their designs can benefit from the expertise of specialized providers like Xi'an Tongzida Technology Co., Ltd., which offers a range of high-quality thermal resistor sensors tailored to diverse applications.

For more information on high current thermal resistor temperature sensors and their applications in overcurrent protection, please contact us at sales11@xatzd.com. Our team of experts is ready to assist you in finding the optimal solution for your specific needs, ensuring the safety and reliability of your electrical systems.