Common Causes of Surface Mounted Thermistor Temperature Sensor Failure

Physical Damage and Environmental Factors

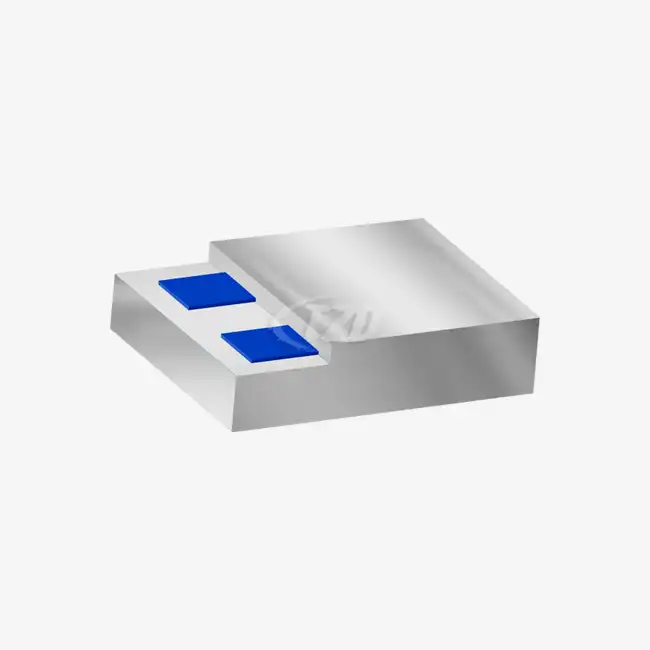

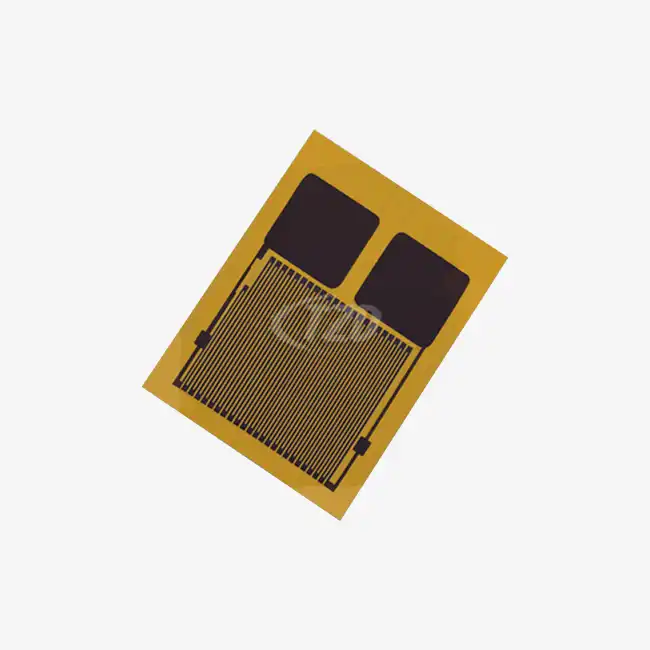

Surface mounted thermistor temperature sensors are delicate components that can be easily damaged by physical forces or harsh environmental conditions. One of the primary causes of failure is mechanical stress, which can occur during installation, maintenance, or normal operation. Excessive vibration or shock can lead to cracks in the sensor's ceramic substrate or damage to the thin-film sensing element, compromising its accuracy and reliability.

Moisture ingress is another significant threat to these sensors. Despite protective coatings and encapsulations, prolonged exposure to high humidity or direct contact with liquids can lead to corrosion of the sensor's internal components or electrical connections. This corrosion can cause erratic readings or complete sensor failure over time.

Thermal shock, which occurs when a sensor is subjected to rapid temperature changes, can also cause failure. The differential expansion and contraction of materials within the sensor can lead to mechanical stress, potentially causing cracks or delamination of the sensing element from its substrate.

Electrical and Circuit-Related Issues

Electrical overstress is a common cause of surface mounted thermistor temperature sensor failure. Applying voltages or currents beyond the sensor's specified limits can result in immediate damage or gradual degradation of the sensing element. This overstress can occur due to power surges, improper circuit design, or mishandling during testing procedures.

Electrostatic discharge (ESD) events pose a significant risk to these sensors, especially during handling and installation. The sensitive nature of the thin-film elements makes them particularly vulnerable to ESD damage, which can cause immediate failure or lead to latent defects that manifest over time.

Poor electrical connections or soldering issues can also contribute to sensor failure. Cold solder joints or improper attachment to the circuit board can result in intermittent connections, leading to erratic temperature readings or complete loss of signal. Additionally, thermal cycling can exacerbate these connection problems, causing solder joint fatigue and eventual failure.

Long-Term Degradation and Calibration Drift

Surface mounted thermistor temperature sensors are subject to long-term degradation that can affect their accuracy and reliability. One of the primary mechanisms of this degradation is calibration drift, where the sensor's resistance-temperature relationship changes over time. This drift can be caused by various factors, including thermal aging of the sensor materials, chemical reactions within the sensor, or subtle physical changes in the sensor structure.

Contamination of the sensor surface can also lead to gradual performance degradation. Dust, oil, or other particulates can accumulate on the sensor, affecting its thermal response and potentially leading to inaccurate temperature measurements. In industrial environments, chemical vapors or corrosive atmospheres can accelerate this degradation process.

Repeated thermal cycling, especially at the extremes of the sensor's operating range, can cause cumulative stress on the sensor materials. This stress can lead to microcracks, changes in the crystalline structure of the sensing element, or alterations in the thermal expansion characteristics of the sensor components. Over time, these changes can result in decreased accuracy or complete sensor failure.

Preventive Measures and Best Practices

Proper Selection and Installation Techniques

Preventing surface mounted thermistor temperature sensor failure begins with proper sensor selection. It's crucial to choose a sensor with specifications that match the application requirements, including temperature range, accuracy, and environmental conditions. Consider factors such as the sensor's thermal coefficient, stability over time, and resistance to environmental stressors when making your selection.

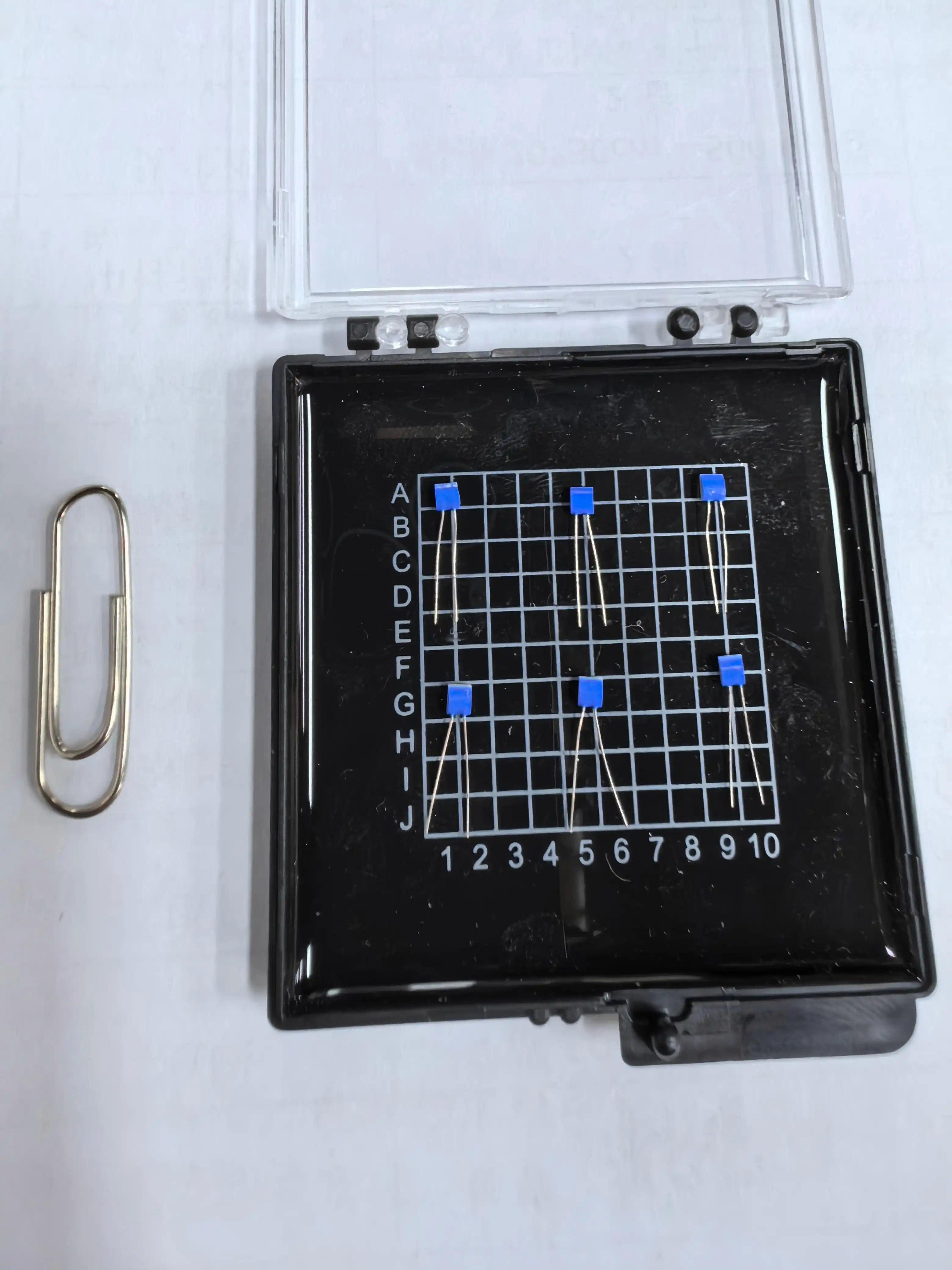

During installation, follow manufacturer guidelines meticulously to avoid damaging the sensor. Use appropriate handling techniques and tools to minimize the risk of mechanical stress or ESD events. Ensure that the mounting surface is clean, flat, and appropriate for the sensor type. When soldering, use temperature-controlled equipment and follow recommended profiles to prevent thermal damage to the sensor.

Proper thermal management is essential for the longevity of surface mounted thermistor temperature sensors. Design the circuit board layout to minimize heat transfer from other components to the sensor. Consider using thermal isolation techniques or heat sinking where necessary to maintain the sensor within its specified operating temperature range.

Environmental Protection and Encapsulation

To protect surface mounted thermistor temperature sensors from harsh environments, consider additional encapsulation or protective coatings. Conformal coatings can provide an effective barrier against moisture and contaminants, extending the sensor's lifespan in high-humidity or corrosive environments. However, ensure that the coating material and application process are compatible with the sensor and do not significantly affect its thermal response.

In applications where mechanical stress or vibration is a concern, use appropriate damping or isolation techniques. This may include using flexible mounting methods or incorporating shock-absorbing materials to protect the sensor from excessive mechanical forces.

For sensors exposed to extreme temperature variations, implement thermal management strategies to minimize thermal shock. This can include gradual temperature ramping during system startup or shutdown, or the use of thermal buffers to moderate rapid temperature changes.

Regular Maintenance and Calibration

Implementing a regular maintenance and calibration schedule is crucial for ensuring the long-term accuracy and reliability of surface mounted thermistor temperature sensors. Periodic visual inspections can help identify early signs of physical damage, corrosion, or contamination. Clean sensors gently using appropriate methods and materials to remove any accumulated debris or contaminants that could affect performance.

Regular calibration checks are essential to detect and correct for any drift in sensor accuracy over time. Develop a calibration schedule based on the sensor's specifications, application requirements, and operating environment. Use traceable reference standards and follow established calibration procedures to ensure accurate results.

In critical applications, consider implementing redundancy or cross-checking mechanisms. Using multiple sensors or complementary measurement techniques can help detect sensor failures or inaccuracies before they lead to system-wide issues.

Advanced Diagnostic and Monitoring Techniques

Implementing Self-Diagnostic Features

Advanced surface mounted thermistor temperature sensors can incorporate self-diagnostic features to detect potential issues before they lead to complete failure. These features may include built-in test circuits that periodically check the sensor's resistance at known temperature points or monitor for sudden changes in sensor characteristics that could indicate damage or degradation.

Some modern sensor designs include redundant sensing elements within a single package. This redundancy allows for continuous comparison between multiple measurements, enabling the detection of discrepancies that might indicate a failing sensor element. Implementing these advanced sensors can significantly improve system reliability and reduce downtime in critical applications.

Data Analysis and Predictive Maintenance

Leveraging data analytics and machine learning techniques can provide valuable insights into sensor health and performance trends. By continuously monitoring and analyzing sensor data, it's possible to detect subtle changes in behavior that may indicate impending failure or calibration drift. This approach enables predictive maintenance strategies, allowing for sensor replacement or recalibration before accuracy is significantly compromised.

Implementing statistical process control (SPC) techniques can help identify outliers or trends in sensor readings that may not be immediately apparent. By establishing control limits and monitoring for shifts in sensor behavior over time, it's possible to proactively address potential issues before they lead to system failures or inaccurate measurements.

Remote Monitoring and IoT Integration

Integrating surface mounted thermistor temperature sensors into Internet of Things (IoT) platforms can enable remote monitoring and management of sensor performance. This connectivity allows for real-time data collection, analysis, and alerting, enabling rapid response to potential sensor issues. Remote diagnostics capabilities can significantly reduce maintenance costs and improve overall system reliability, especially for sensors deployed in hard-to-reach or hazardous environments.

IoT integration also facilitates the collection of large-scale sensor performance data across multiple installations or applications. This wealth of data can be used to refine sensor designs, improve calibration techniques, and develop more accurate predictive maintenance models, ultimately leading to more reliable and longer-lasting temperature measurement systems.

Conclusion

Understanding the causes of surface mounted thermistor temperature sensor failure is crucial for maintaining accurate and reliable temperature measurement systems across various industries. By implementing proper selection, installation, and maintenance practices, along with advanced diagnostic and monitoring techniques, it's possible to significantly extend sensor lifespan and improve overall system performance. As technology continues to advance, the integration of smart sensors with self-diagnostic capabilities and IoT connectivity will further enhance our ability to prevent and predict sensor failures, ensuring more reliable and efficient temperature monitoring solutions.

For more information on high-quality surface mounted thermistor temperature sensors and expert guidance on implementing reliable temperature measurement solutions, please contact us at sales11@xatzd.com. Our team of specialists is ready to assist you in selecting the right sensors for your application and developing strategies to maximize their performance and longevity.