Design and Composition of Ultra-Thin Flexible Temperature Sensors

Materials and Construction

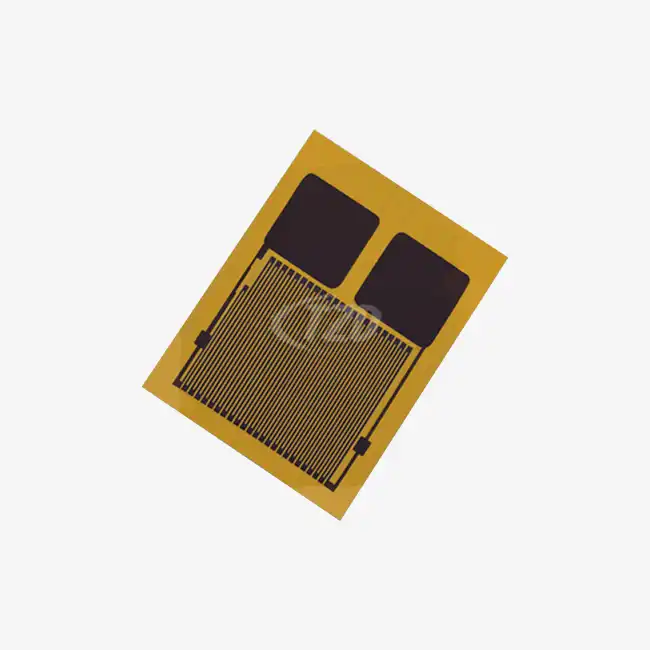

Ultra-thin flexible temperature sensors are marvels of modern engineering, combining advanced materials science with precision manufacturing techniques. These sensors often utilize thin-film platinum as the sensing element, known for its exceptional stability and linear temperature-resistance relationship. The platinum layer, typically only a few nanometers thick, is deposited on a flexible substrate such as polyimide or polyester.

The construction process involves several intricate steps, including photolithography and etching, to create the precise patterns necessary for accurate temperature sensing. The resulting structure is then encapsulated in a protective layer that shields the sensitive components from environmental factors while maintaining flexibility.

Dimensions and Customization

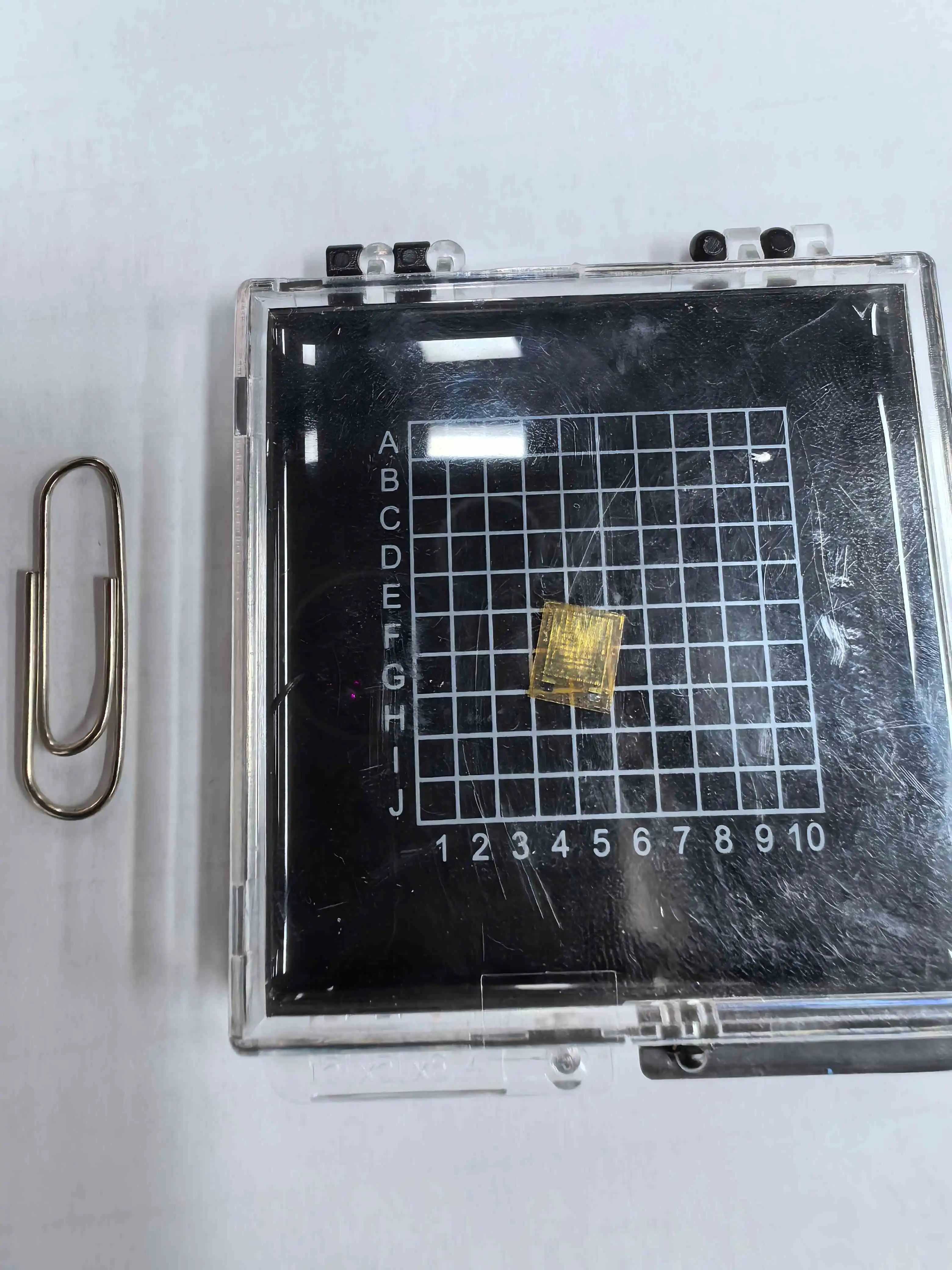

One of the most remarkable aspects of ultra-thin flexible temperature sensors is their minuscule size. With dimensions as small as 7mm x 5mm x 0.05mm, these sensors can be integrated into spaces where conventional sensors simply cannot fit. Moreover, manufacturers offer customization options, allowing users to tailor the sensor's dimensions to their specific application requirements.

The ability to customize not only the size but also the shape of these sensors opens up a plethora of possibilities for designers and engineers. From curved surfaces to tight corners, ultra-thin flexible temperature sensors can conform to almost any geometry, ensuring accurate temperature measurements in even the most challenging environments.

Temperature Range and Accuracy

Despite their diminutive size, ultra-thin flexible temperature sensors boast impressive performance characteristics. They typically operate across a wide temperature range, from -70°C to +200°C, making them suitable for diverse applications from cryogenic processes to high-temperature industrial settings.

Accuracy is paramount in temperature sensing, and these sensors deliver. They are available in different grades, with Class A sensors offering accuracy up to ±0.6°C and Class B sensors providing ±1.2°C accuracy. This level of precision is crucial for applications in medical diagnostics, scientific research, and quality control in manufacturing processes.

Technical Specifications and Performance Metrics

Base Resistance and Temperature Coefficient

The base resistance of ultra-thin flexible temperature sensors is a critical parameter that can be specified according to the requirements of the application. This flexibility in resistance values allows for optimal integration with various readout circuits and systems.

The temperature coefficient of resistance (TCR) is another crucial specification, typically around 6444 ppm/°C for these sensors. This high TCR value ensures excellent sensitivity to temperature changes, enabling rapid and accurate measurements. The linear relationship between resistance and temperature simplifies calibration and interpretation of sensor outputs.

Response Time and Stability

Ultra-thin flexible temperature sensors excel in their rapid response to temperature changes. With response times as low as 0.05 seconds, these sensors can capture quick temperature fluctuations that might be missed by slower, traditional sensors. This rapid response is particularly valuable in dynamic environments or processes where temperature control is critical.

Long-term stability is another hallmark of these sensors. With drift rates typically less than 0.04% over extended periods, users can rely on consistent and accurate measurements without frequent recalibration. This stability is achieved through careful material selection and advanced manufacturing processes that minimize material degradation over time.

Durability and Environmental Resistance

Despite their delicate appearance, ultra-thin flexible temperature sensors are surprisingly robust. They can withstand vibrations up to 40g and impacts up to 100g, making them suitable for use in harsh industrial environments and mobile applications. This durability is achieved through careful design of the sensor structure and the use of high-quality, flexible encapsulation materials.

The sensors are also designed to resist various environmental factors. Many models offer protection against moisture, chemicals, and electromagnetic interference, ensuring reliable operation in diverse settings. This environmental resistance, combined with their flexibility, allows these sensors to be used in applications where traditional rigid sensors would fail.

Applications and Industry Impact

Medical and Wearable Technologies

The medical field has embraced ultra-thin flexible temperature sensors with enthusiasm. These sensors enable continuous, non-invasive temperature monitoring in patients, providing valuable data for diagnosing and treating various conditions. In wearable health devices, these sensors can be integrated into patches or garments, offering users real-time body temperature tracking without discomfort or inconvenience.

Beyond simple temperature monitoring, these sensors are finding applications in advanced medical treatments. For example, in hyperthermia therapy for cancer treatment, ultra-thin flexible temperature sensors can provide precise temperature control, enhancing treatment efficacy while minimizing risks to surrounding healthy tissue.

Industrial and Manufacturing Applications

In the industrial sector, ultra-thin flexible temperature sensors are revolutionizing process control and quality assurance. Their ability to conform to irregular surfaces allows for temperature monitoring in previously inaccessible areas of machinery or products. This capability is particularly valuable in industries such as electronics manufacturing, where temperature control during production is critical for product quality and reliability.

The automotive industry is another sector benefiting from these sensors. They can be integrated into battery systems for electric vehicles, providing crucial temperature data to optimize performance and prevent overheating. In aerospace applications, these sensors offer lightweight, space-efficient solutions for monitoring temperatures across aircraft structures and systems.

Research and Development

The unique properties of ultra-thin flexible temperature sensors make them invaluable tools in scientific research. They enable temperature measurements in scenarios where traditional sensors would be too intrusive or impractical. For instance, in materials science, these sensors can be embedded within composite materials to study temperature distributions during curing processes.

In environmental research, ultra-thin flexible temperature sensors are being used to study microclimates and thermal gradients in ecosystems. Their low profile and flexibility allow for minimal disruption to the environments being studied, providing more accurate and representative data.

Conclusion

Ultra-thin flexible temperature sensors represent a significant advancement in temperature measurement technology. Their unique combination of flexibility, accuracy, and durability opens up new possibilities across a wide range of industries and applications. As research and development in this field continue, we can expect to see even more innovative uses for these remarkable sensors, further pushing the boundaries of what's possible in temperature sensing and control.

For those interested in exploring the potential of ultra-thin flexible temperature sensors for their specific applications, Xi'an Tongzida Technology Co., Ltd. offers customized solutions and expert guidance. To learn more about our products and services, please contact us at sales11@xatzd.com. Our team of specialists is ready to assist you in finding the perfect temperature sensing solution for your needs.