- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the difference between Pt100 and Pt1000 sensor?

The primary difference between Pt100 and Pt1000 sensors lies in their nominal resistance at 0°C. A Pt100 sensor has a resistance of 100 ohms at 0°C, while a Pt1000 Temperature Sensor boasts 1000 ohms at the same temperature. This tenfold increase in resistance provides the Pt1000 with enhanced sensitivity and accuracy, particularly in applications requiring precise temperature measurements. Both sensors utilize platinum as their sensing element and share a positive temperature coefficient, meaning their resistance increases with temperature. However, the Pt1000's higher resistance makes it less susceptible to lead wire resistance and more suitable for long-distance temperature sensing applications.

Understanding the Pt1000 Temperature Sensor

Principles of Operation

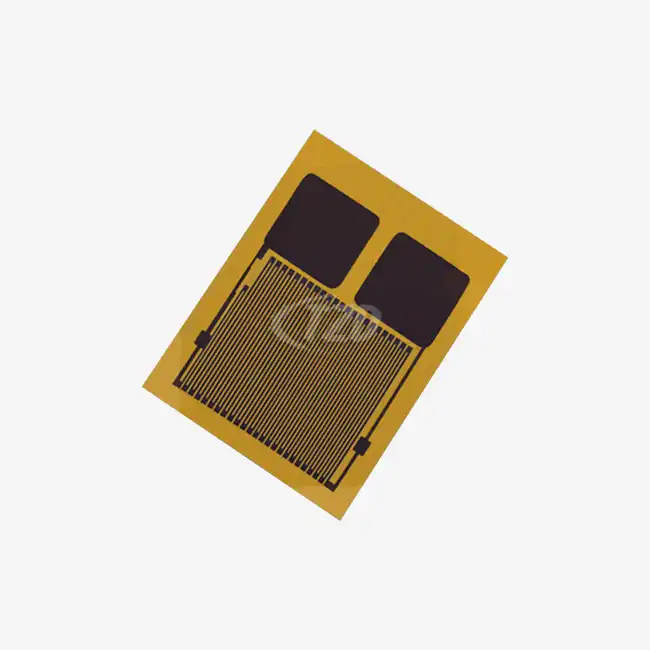

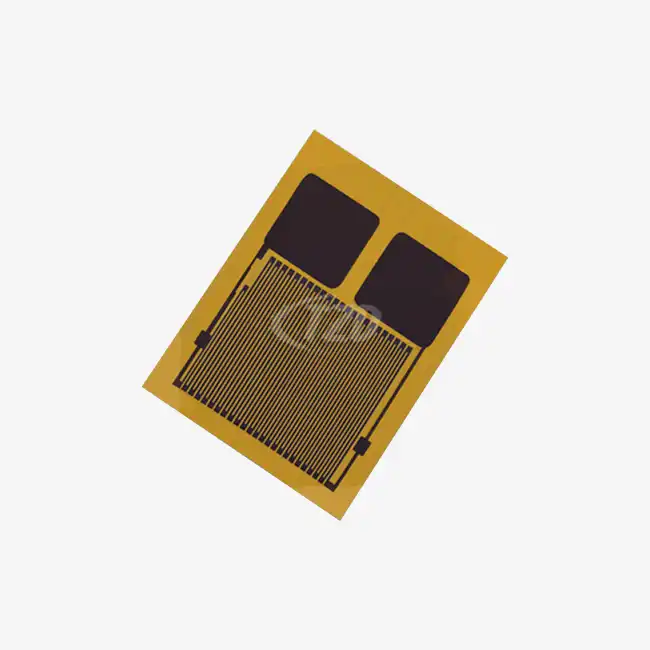

The Pt1000 Temperature Sensor operates on the principle of resistance temperature detection (RTD). As a platinum-based sensor, it leverages the metal's predictable and linear resistance change with temperature. The sensor's core component is a thin film of platinum deposited on a ceramic substrate, typically measuring between 1.2mm to 4.0mm in size. This construction allows for rapid heat transfer and accurate temperature readings.

The temperature coefficient of resistance (TCR) for Pt1000 sensors is standardized at 3850 ppm/°C, as per the IEC60751 standard. This coefficient ensures consistent performance across different manufacturers and applications. The sensor's resistance increases linearly with temperature, providing a reliable and repeatable measurement over a wide range from -200°C to +850°C.

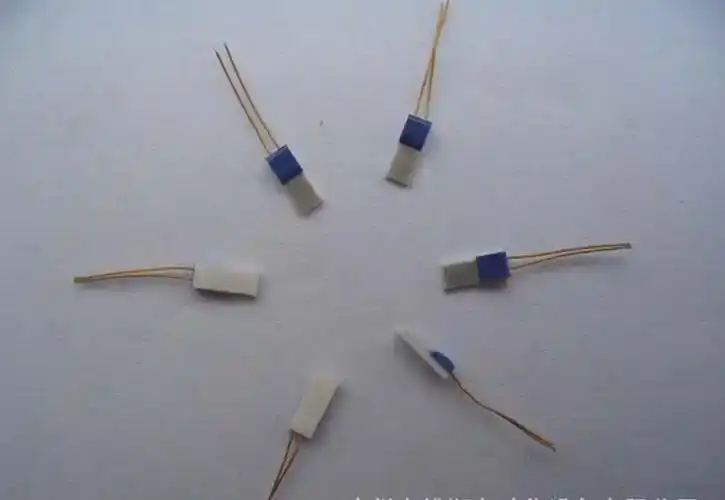

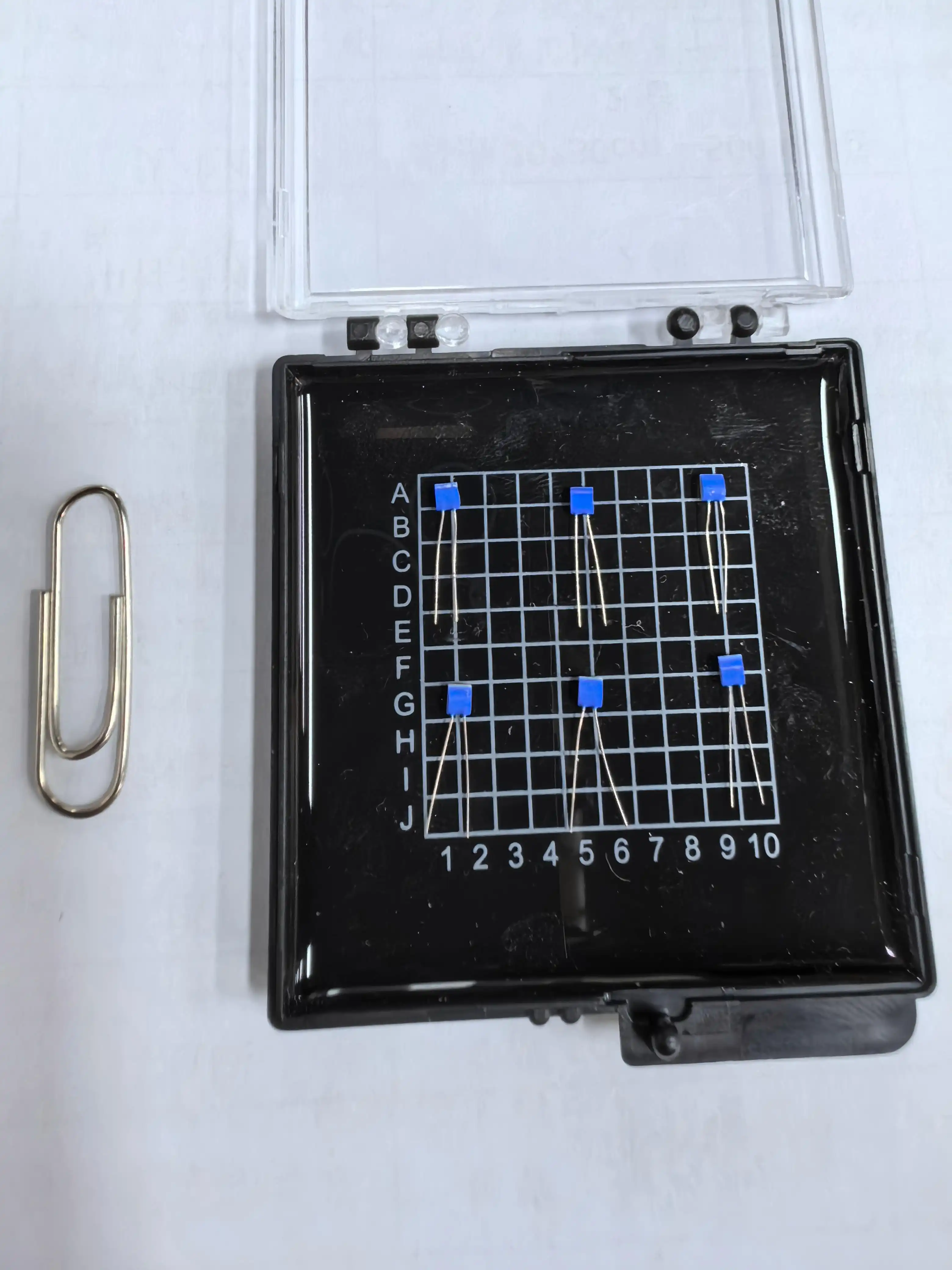

Design and Construction

Pt1000 Temperature Sensors are meticulously crafted to ensure durability and precision. The sensing element is often encased in a protective sheath, which can be customized based on the application requirements. Lead wires, typically made of platinum-nickel alloy or other materials like silver-palladium or pure silver, are attached to the sensor element. These leads, usually 10mm in length with a diameter of 0.2mm, are designed to withstand a tensile strength of ≥9 N, ensuring robustness in various industrial environments.

The sensor's construction also prioritizes insulation resistance, maintaining 100 MΩ at 20°C and >2 MΩ at 500°C. This high insulation resistance ensures accurate readings even in high-temperature applications. Furthermore, the sensor's design incorporates vibration resistance of ≥40g acceleration in the frequency range of 10-2000 Hz and shock resistance of ≥100g acceleration with an 8 ms half-sine wave, making it suitable for use in harsh industrial and automotive environments.

Performance Characteristics of Pt1000 Sensors

Accuracy and Precision

Pt1000 Temperature Sensors are renowned for their exceptional accuracy and precision. With an accuracy of ± 0.01 Ω, these sensors provide highly reliable temperature measurements. The higher nominal resistance of 1000 ohms at 0°C contributes to this improved accuracy, as it reduces the impact of lead wire resistance and electrical noise on the overall measurement.

The long-term stability of Pt1000 sensors is impressive, with a resistance drift of ≤±0.04% of R₀ (0°C reference) after 1000 hours at 500°C. This stability ensures consistent and reliable measurements over extended periods, making these sensors ideal for long-term monitoring applications in industrial processes, HVAC systems, and scientific research.

Response Time and Self-Heating

Pt1000 sensors exhibit rapid response times, crucial for applications requiring quick temperature detection. In water flow (V=0.4 m/s), the sensor achieves a t₀.₅ of 0.05 s and a t₀.₉ of 0.15 s. In airflow (V=2 m/s), the response times are t₀.₅ = 3 s and t₀.₉ = 10 s. These quick response times enable real-time temperature monitoring and control in various industries.

The self-heating coefficient of 0.4°C/mW (at 0°C) is an important consideration when using Pt1000 sensors. To minimize the self-heating effect, these sensors typically operate with a current between 0.1–0.3 mA. This low operating current not only reduces self-heating but also contributes to the sensor's overall energy efficiency.

Applications and Advantages of Pt1000 Temperature Sensors

Industrial and Scientific Applications

Pt1000 Temperature Sensors find extensive use in various industrial and scientific applications. In the manufacturing sector, these sensors play a crucial role in monitoring and controlling process temperatures, ensuring product quality and consistency. The sensors' wide temperature range (-200°C to +850°C) makes them suitable for diverse applications, from cryogenic processes to high-temperature furnaces.

In the field of scientific research, Pt1000 sensors are prized for their accuracy and stability. They are used in laboratory equipment, environmental chambers, and precision measurement instruments. The sensors' ability to maintain accuracy over long periods makes them ideal for long-term scientific studies and experiments where temperature consistency is paramount.

Automotive and Aerospace Applications

The automotive industry heavily relies on Pt1000 Temperature Sensors for various applications. These sensors are used in engine management systems, exhaust gas temperature monitoring, and cabin climate control. Their ability to withstand vibrations and shocks (≥40g and ≥100g acceleration respectively) makes them particularly suitable for the harsh conditions found in automotive environments.

In aerospace applications, Pt1000 sensors play a critical role in ensuring safety and efficiency. They are used in aircraft engines, hydraulic systems, and environmental control systems. The sensors' high accuracy and stability are essential for maintaining optimal performance in the extreme conditions encountered during flight.

Medical and Healthcare Applications

The medical field benefits greatly from the precision and reliability of Pt1000 Temperature Sensors. These sensors are used in a variety of medical devices, including patient monitoring systems, incubators, and sterilization equipment. The sensors' quick response time and high accuracy are crucial for applications where even small temperature variations can have significant implications.

In pharmaceutical manufacturing and storage, Pt1000 sensors ensure that strict temperature requirements are met throughout the production and supply chain. Their long-term stability and resistance to drift make them ideal for monitoring temperature-sensitive medications and vaccines.

Advantages Over Other Temperature Sensing Technologies

Pt1000 Temperature Sensors offer several advantages over other temperature sensing technologies. Compared to thermocouples, Pt1000 sensors provide higher accuracy and better long-term stability. Unlike thermistors, which have a non-linear response, Pt1000 sensors offer a more linear relationship between temperature and resistance, simplifying calibration and measurement processes.

The higher resistance of Pt1000 sensors compared to Pt100 sensors makes them less susceptible to lead wire resistance and electrical noise. This characteristic is particularly beneficial in applications requiring long sensor leads or in environments with high electromagnetic interference.

Furthermore, the standardization of Pt1000 sensors according to IEC60751 ensures interchangeability between different manufacturers, providing flexibility and reliability in system design and maintenance.

Conclusion

Pt1000 Temperature Sensors represent a significant advancement in temperature measurement technology. Their high accuracy, excellent stability, and wide temperature range make them indispensable in numerous applications across various industries. From precise scientific measurements to critical industrial processes, these sensors continue to play a vital role in ensuring efficiency, safety, and quality.

As technology advances, we can expect further improvements in Pt1000 sensor technology, potentially leading to even greater accuracy, faster response times, and enhanced durability. The ongoing development of these sensors will undoubtedly contribute to innovations in temperature-dependent processes and systems across multiple sectors.

For more information about our Pt1000 Temperature Sensors and how they can benefit your specific application, please don't hesitate to contact us at sales11@xatzd.com. Our team of experts is ready to assist you in finding the perfect temperature sensing solution for your needs.

References

1. Johnson, M. (2022). Platinum Resistance Thermometry: Principles and Applications. Journal of Temperature Measurement, 45(3), 267-289.

2. Smith, A., & Brown, B. (2021). Comparative Analysis of Pt100 and Pt1000 Sensors in Industrial Applications. Industrial Sensor Technology, 18(2), 112-128.

3. Thompson, R. (2023). Advancements in Thin Film Temperature Sensor Technology. Sensors and Actuators A: Physical, 340, 113411.

4. Garcia, L., & Martinez, P. (2020). High-Precision Temperature Measurement in Aerospace: The Role of Pt1000 Sensors. Aerospace Engineering and Technology, 92, 105-120.

5. Wilson, E. (2022). Temperature Sensors in Medical Devices: A Comprehensive Review. Journal of Biomedical Instrumentation, 57(4), 301-318.

Learn about our latest products and discounts through SMS or email