Grasping the Principles and Types of Thermistor Temperature Sensors

The Science Behind Thermistor Operation

Thermistors are a type of resistor whose resistance is highly dependent on temperature. They are constructed using semiconductor materials, typically metal oxides or ceramics, which exhibit a significant change in resistance with even slight temperature fluctuations. This property makes thermistors exceptionally sensitive and accurate for temperature measurement.

There are two main types of thermistors: Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC). NTC thermistors decrease in resistance as temperature increases, while PTC thermistors increase in resistance with rising temperatures. NTC thermistors are more commonly used due to their wider temperature range and higher sensitivity.

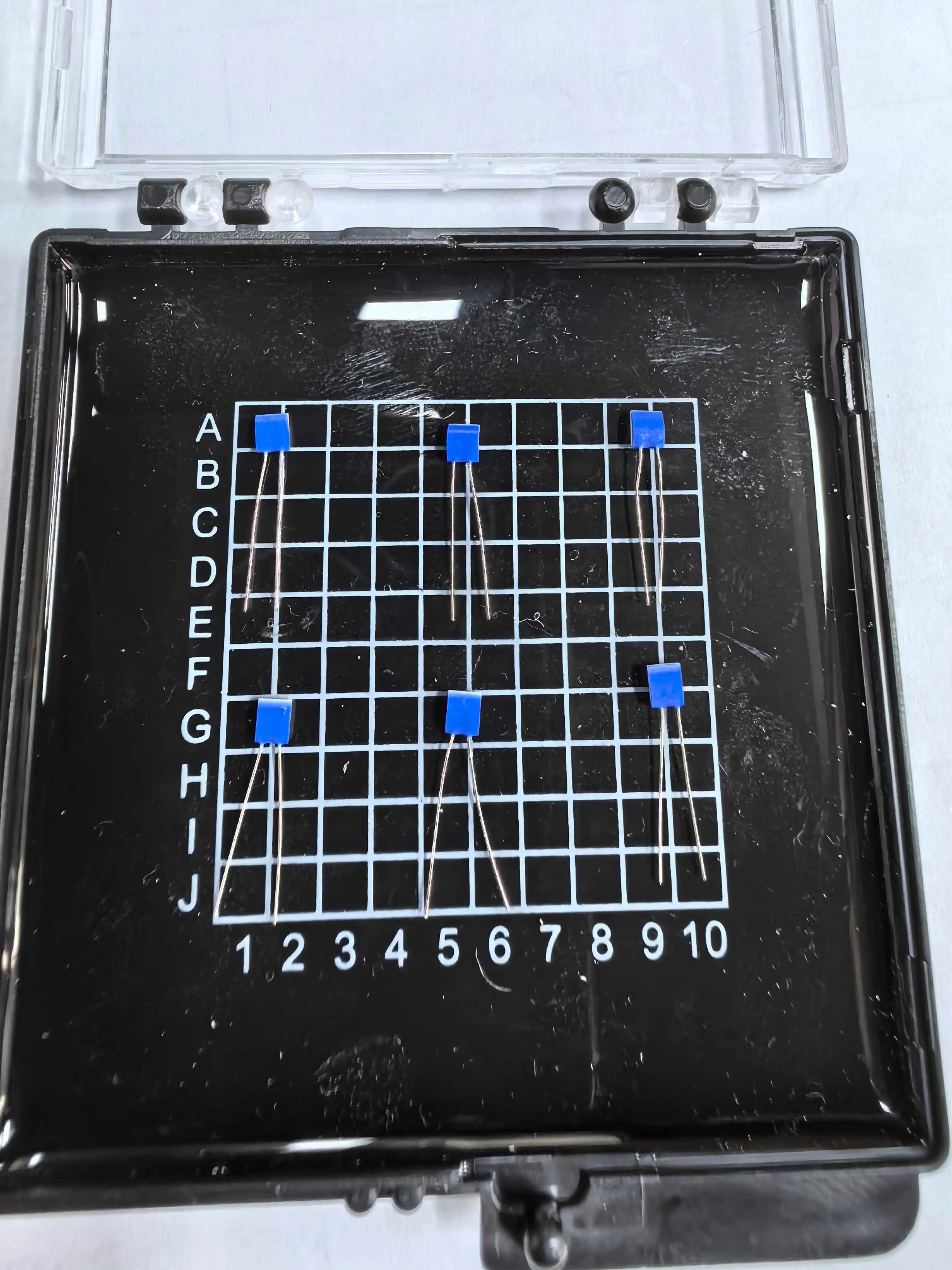

Probe Type Thermistor Temperature Sensors: Design and Advantages

Probe type thermistor temperature sensors are specifically designed for applications requiring direct and precise temperature measurement in a wide range of mediums. These sensors feature a thermistor element securely housed within a protective probe, typically constructed from stainless steel or other corrosion-resistant, durable materials. This robust design enables straightforward insertion into liquids, gases, or solid surfaces, ensuring reliable thermal contact and accurate readings. They are ideal for industrial processes, laboratory environments, food safety monitoring, and HVAC systems.

The advantages of probe type thermistor temperature sensors include:

- High accuracy and sensitivity

- Fast response times

- Durability and resistance to harsh environments

- Versatility in application across different industries

- Cost-effectiveness compared to other temperature sensing technologies

Applications Across Industries

Probe type thermistor temperature sensors find applications in numerous industries due to their reliability and precision. In the medical field, they are used in patient monitoring systems and diagnostic equipment. The automotive industry utilizes these sensors for engine temperature control and climate systems. In industrial processes, they play a crucial role in maintaining optimal operating temperatures for machinery and equipment.

Advanced Features of Modern Thermistor Temperature Sensors

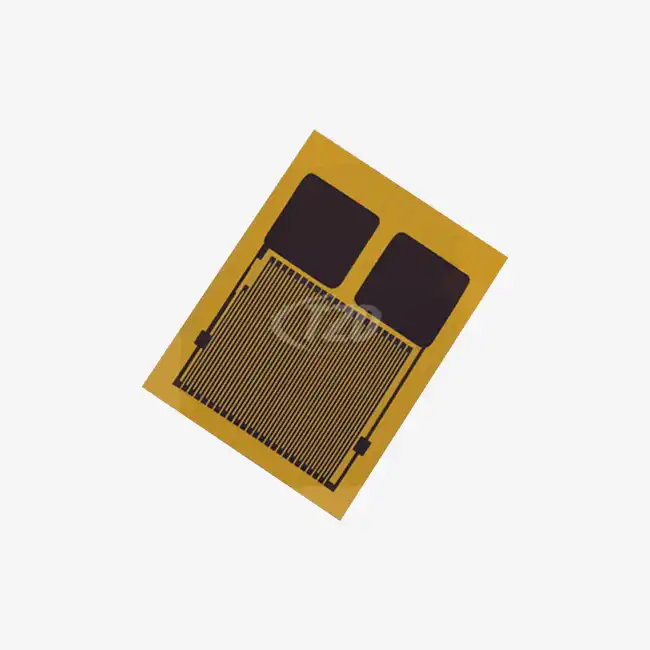

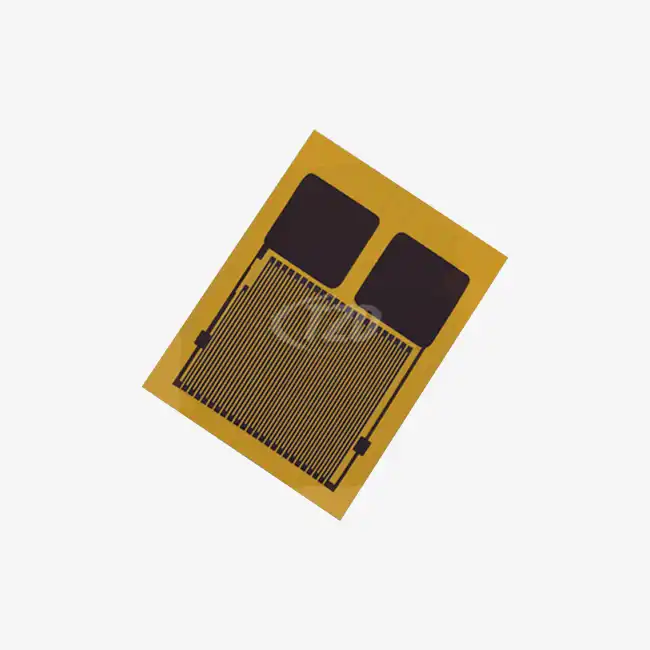

Cutting-Edge Manufacturing Techniques

Present day thermistor temperature sensors advantage from progressed fabricating procedures that upgrade their execution and unwavering quality. Thin film technology, for instance, allows for the creation of highly sensitive and stable thermistors. Companies like Xi'an Tongzida Technology Co., Ltd. have established sophisticated platforms for designing, processing, packaging, and testing thin film temperature sensitive chips.

These advanced manufacturing processes result in thermistors with exceptional characteristics, such as:

- Temperature coefficients as precise as 3850ppm/℃

- Wide operating temperature ranges (e.g., -200℃ to +850℃)

- Accuracy levels of ±0.01 Ω

- Long-term stability with drift ≤ 0.04%

Customization and Adaptability

Present day test sort thermistor temperature sensors offer a tall degree of customization to meet different application necessities over businesses. Producers can create these sensors in a wide extend of sizes, ordinarily from 1.2mm to 4.0mm in distance across, pleasing establishments with strict spatial impediments. Moreover, users can select from various lead materials—including platinum nickel, silver nickel, and pure platinum—depending on factors such as temperature range, environmental conditions, electrical conductivity, and compatibility with specific systems or devices.

Enhanced Durability and Performance

Today's thermistor sensors are designed to withstand challenging environments. High-quality probe type thermistor temperature sensors can offer:

- Rapid response times, as fast as 0.05 seconds

- Vibration resistance up to 40g

- Impact resistance of 100g

These features make modern thermistors suitable for high-demand scenarios in industrial, medical, automotive, and aerospace applications where reliability under extreme conditions is paramount.

Optimizing Temperature Measurement with Thermistor Sensors

Best Practices for Installation and Maintenance

To ensure optimal performance of probe type thermistor temperature sensors, proper installation and maintenance are crucial. Key considerations include:

- Proper positioning of the sensor for accurate readings

- Ensuring good thermal contact between the sensor and the measured medium

- Regular calibration to maintain accuracy over time

- Protection from electromagnetic interference and mechanical stress

- Periodic inspection and cleaning to prevent contamination

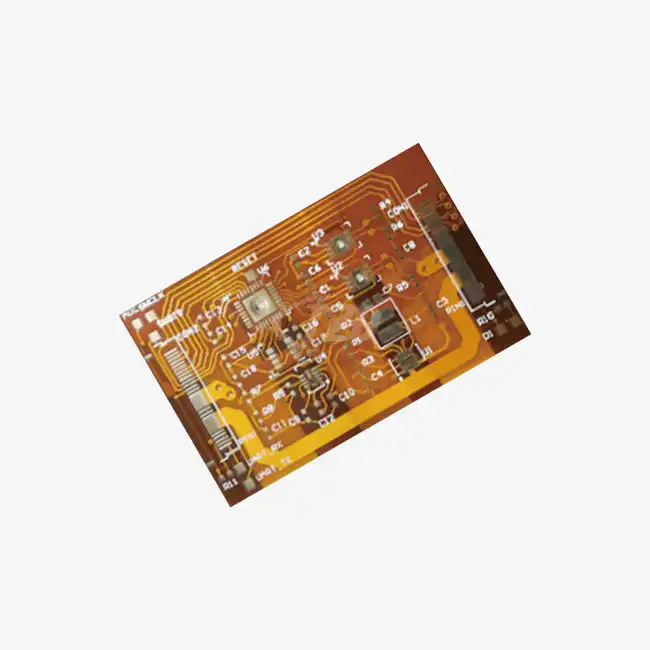

Integration with Control Systems

Thermistor temperature sensors can be seamlessly integrated into larger control systems, enabling automated temperature regulation, real-time monitoring, and responsive adjustments for improved efficiency and operational reliability across various applications. This integration often involves:

- Analog-to-digital conversion of sensor outputs

- Implementation of temperature compensation algorithms

- Integration with PLC or SCADA systems for real-time monitoring and control

- Development of custom software for data analysis and reporting

Future Trends and Innovations

The field of thermistor temperature sensing continues to evolve, with emerging trends including:

- Miniaturization for use in increasingly compact devices

- Integration with IoT systems for remote monitoring and predictive maintenance

- Development of self-calibrating sensors to reduce maintenance requirements

- Utilization of advanced materials for even greater sensitivity and stability

Conclusion

Probe type thermistor temperature sensors play a vital role in modern temperature measurement and control applications. Their high accuracy, fast response times, and versatility make them indispensable across various industries. As technology continues to advance, these sensors are becoming even more sophisticated, offering improved performance and reliability.

For those seeking high-quality thermistor temperature sensors or custom solutions for specific applications, Xi'an Tongzida Technology Co., Ltd. offers a range of advanced options. Their expertise in thin film technology and commitment to quality ensure that customers receive sensors that meet the most demanding requirements. For more information or to discuss your specific needs, please contact them at sales11@xatzd.com.