Understanding the Technology Behind Thin Film Platinum Resistors

Manufacturing Process and Material Properties

The production of Thin Film Platinum Resistor Pt100-SMD involves a sophisticated manufacturing process that leverages cutting-edge technology. These resistors are crafted by depositing a thin layer of platinum onto a ceramic substrate, typically made of alumina. The platinum film, measuring mere nanometers in thickness, is meticulously patterned to achieve the desired resistance value.

The use of platinum as the sensing element is not arbitrary. Platinum's unique properties make it an ideal material for temperature sensing applications. It exhibits a highly linear and predictable resistance change with temperature, characterized by a temperature coefficient of resistance (TCR) of 3850 ppm/°C. This linearity ensures accurate temperature measurements across a wide range.

Moreover, platinum's chemical inertness contributes to the sensor's long-term stability. Unlike other metals, platinum resists oxidation and corrosion, even at elevated temperatures. This characteristic is crucial for maintaining measurement accuracy over extended periods, with a typical long-term stability of ≤±0.06% resistance drift of R₀°C after 1000 hours at 200°C.

Design Considerations and Specifications

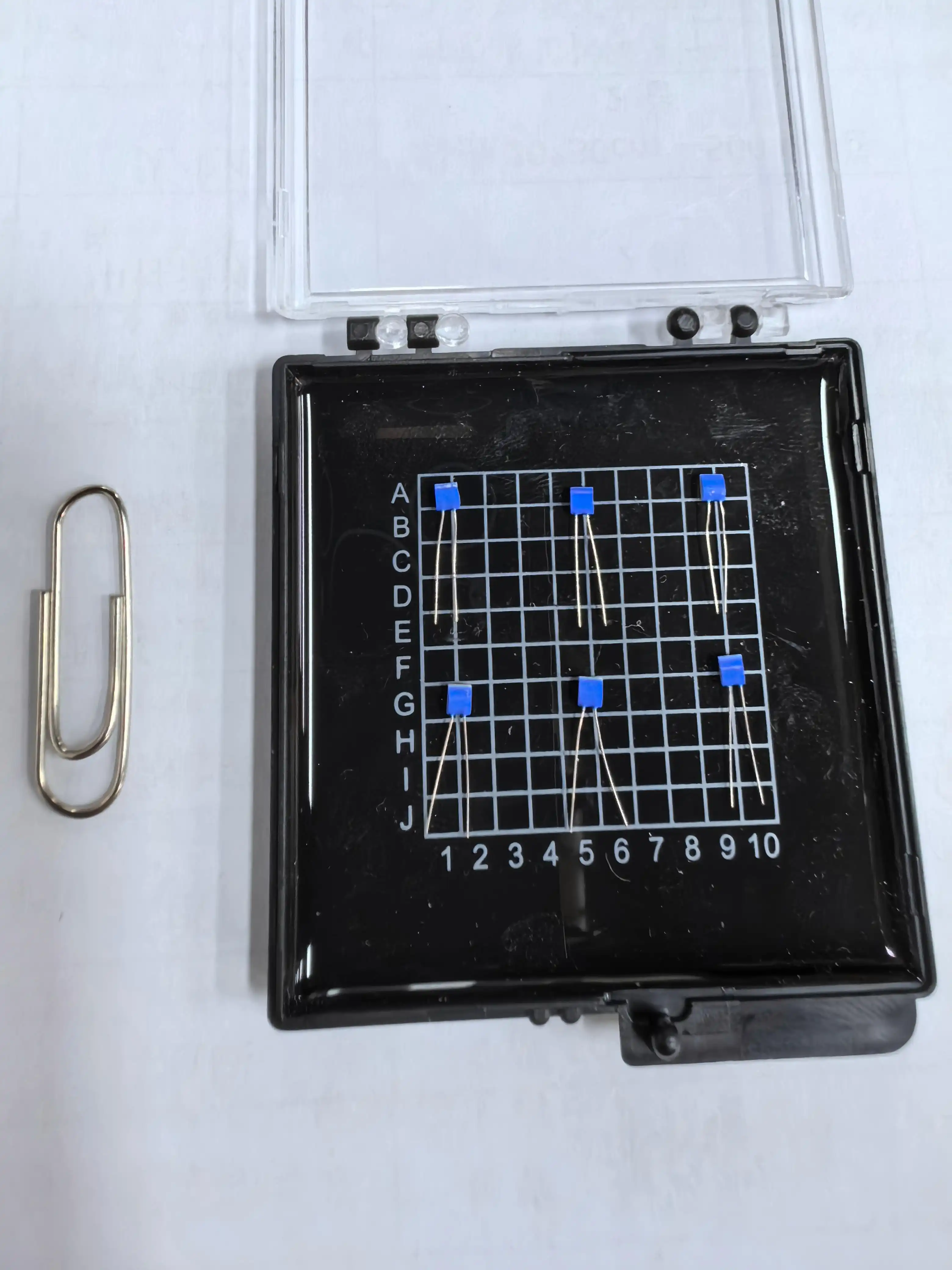

The design of Thin Film Platinum Resistor Pt100-SMD components takes into account various factors to optimize performance and reliability. The element dimensions, typically 3.2mm x 1.6mm x 0.7mm, strike a balance between miniaturization and thermal response. This compact size allows for easy integration into space-constrained circuits while maintaining excellent thermal characteristics.

The temperature measurement range of -50°C to +200°C makes these resistors versatile for a wide array of applications. However, it's worth noting that some advanced models can cover an even broader range, from -200°C to +850°C, catering to extreme temperature scenarios.

The choice of terminal materials and construction is another critical aspect of the design. Tin alloy terminals are commonly used, offering good solderability and resistance to thermal fatigue. The recommended soldering methods include reflow soldering or wave soldering, with a soldering temperature of 230-240°C. High-temperature solder paste is recommended to ensure reliable connections that can withstand thermal cycling.

Advantages of Thin Film Platinum Resistors in Circuit Applications

Precision and Stability in Temperature Measurement

One of the primary advantages of Thin Film Platinum Resistor Pt100-SMD components is their exceptional precision in temperature measurement. The platinum sensing element, combined with the thin film construction, allows for an accuracy of ± 0.01 Ω. This level of precision is crucial in applications where even slight temperature variations can have significant impacts, such as in medical equipment or industrial process control.

The stability of these resistors is equally impressive. With a long-term stability drift of ≤ 0.04%, they maintain their accuracy over extended periods, even in harsh environments. This stability is particularly valuable in applications requiring long-term monitoring or in systems where frequent recalibration is impractical or costly.

Rapid Response and Environmental Resilience

The thin film construction of these resistors contributes to their rapid response time, which can be as low as 0.05 seconds. This quick response is essential in applications where fast temperature changes need to be detected and acted upon promptly, such as in automotive safety systems or industrial process control.

Environmental resilience is another key advantage of Thin Film Platinum Resistor Pt100-SMD components. They exhibit impressive vibration resistance of up to 40g and impact resistance of 100g. This robustness makes them suitable for use in harsh industrial environments, automotive applications, and aerospace systems where mechanical stress is a constant concern.

Versatility and Customization Options

The versatility of Thin Film Platinum Resistor Pt100-SMD components is evident in their wide range of customization options. Manufacturers offer these resistors in multiple sizes, ranging from 1.2mm to 4.0mm, allowing designers to choose the optimal size for their specific application requirements.

Furthermore, various lead materials are available, including platinum nickel, silver nickel, and pure platinum. This variety enables engineers to select the most suitable option based on factors such as environmental conditions, temperature range, and cost considerations.

The customization extends to the resistance values and temperature coefficients as well. While the standard TCR is 3850 ppm/°C, other options may be available to meet specific application needs. This flexibility makes Thin Film Platinum Resistor Pt100-SMD components adaptable to a wide range of circuit designs and temperature sensing requirements.

Implementation Challenges and Best Practices

Circuit Integration and Signal Conditioning

While Thin Film Platinum Resistor Pt100-SMD components offer numerous advantages, their implementation in circuits requires careful consideration. The low resistance values and small resistance changes with temperature necessitate precise signal conditioning circuitry.

Typically, a constant current source is used to excite the platinum resistor, and the voltage drop across it is measured. This voltage is then amplified and converted to a digital signal for processing. The design of this signal conditioning circuit is critical to achieving the full potential of the sensor's accuracy.

Considerations such as self-heating effects, lead wire resistance compensation, and noise reduction must be addressed in the circuit design. Techniques like four-wire connections and excitation current reversal can be employed to mitigate these issues and improve measurement accuracy.

Thermal Management and Mounting Considerations

Proper thermal management is essential when implementing Thin Film Platinum Resistor Pt100-SMD components. The small size of these sensors makes them susceptible to self-heating effects, which can introduce measurement errors if not properly managed.

The mounting of the sensor is also crucial. Good thermal contact with the measured surface or medium must be ensured while also protecting the sensor from mechanical stress. In some cases, thermal compound or specialized mounting adapters may be necessary to optimize heat transfer and measurement accuracy.

Additionally, the placement of the sensor within the overall system must be carefully considered. Factors such as heat sources, airflow, and thermal gradients can all affect the sensor's performance and must be accounted for in the design process.

Calibration and Maintenance Strategies

While Thin Film Platinum Resistor Pt100-SMD components are known for their stability, periodic calibration is still recommended to ensure ongoing accuracy. The calibration process typically involves comparing the sensor's output to a known reference temperature at multiple points across its operating range.

Maintenance strategies should include regular inspection for physical damage, corrosion, or contamination. In harsh environments, protective coatings or enclosures may be necessary to extend the sensor's lifespan and maintain its performance.

It's also important to establish a system for tracking the sensor's performance over time. This can help identify any drift or degradation early, allowing for timely recalibration or replacement before measurement accuracy is compromised.

Conclusion

Thin Film Platinum Resistor Pt100-SMD components have emerged as a cornerstone of precision temperature measurement in modern circuit design. Their combination of accuracy, stability, and versatility makes them indispensable in a wide range of applications, from industrial process control to medical diagnostics and beyond.

As technology continues to advance, we can expect further improvements in the performance and capabilities of these sensors. Engineers and designers who master the implementation of Thin Film Platinum Resistor Pt100-SMD components will be well-positioned to create innovative and high-performance temperature sensing solutions.

For more information about our advanced Thin Film Platinum Resistor Pt100-SMD products and how they can benefit your circuit designs, please contact us at sales11@xatzd.com. Our team of experts is ready to assist you in selecting the optimal solution for your specific application needs.