The Science Behind Pt100 Temperature Sensing Elements

Pt100 temperature sensing elements are at the heart of modern temperature measurement technology. These sensors utilize the principle of electrical resistance change in platinum as a function of temperature. As the temperature increases, the resistance of the platinum element rises in a highly predictable and nearly linear manner.

Platinum's Unique Properties for Temperature Sensing

Platinum possesses several characteristics that make it exceptionally suitable for temperature measurement:

- High purity: Platinum can be refined to extreme levels of purity, ensuring consistent performance across sensors.

- Chemical inertness: Resistant to oxidation and corrosion, platinum maintains its properties even in harsh environments.

- Stability: Platinum exhibits minimal drift over time, contributing to long-term measurement accuracy.

- Linear response: The resistance-temperature relationship of platinum is nearly linear, simplifying calibration and interpretation of readings.

These properties collectively contribute to the reliability and accuracy of Pt100 Temperature Sensing Element sensors, making them indispensable in critical applications where precise temperature control is paramount.

The Structure of Pt100 Sensors

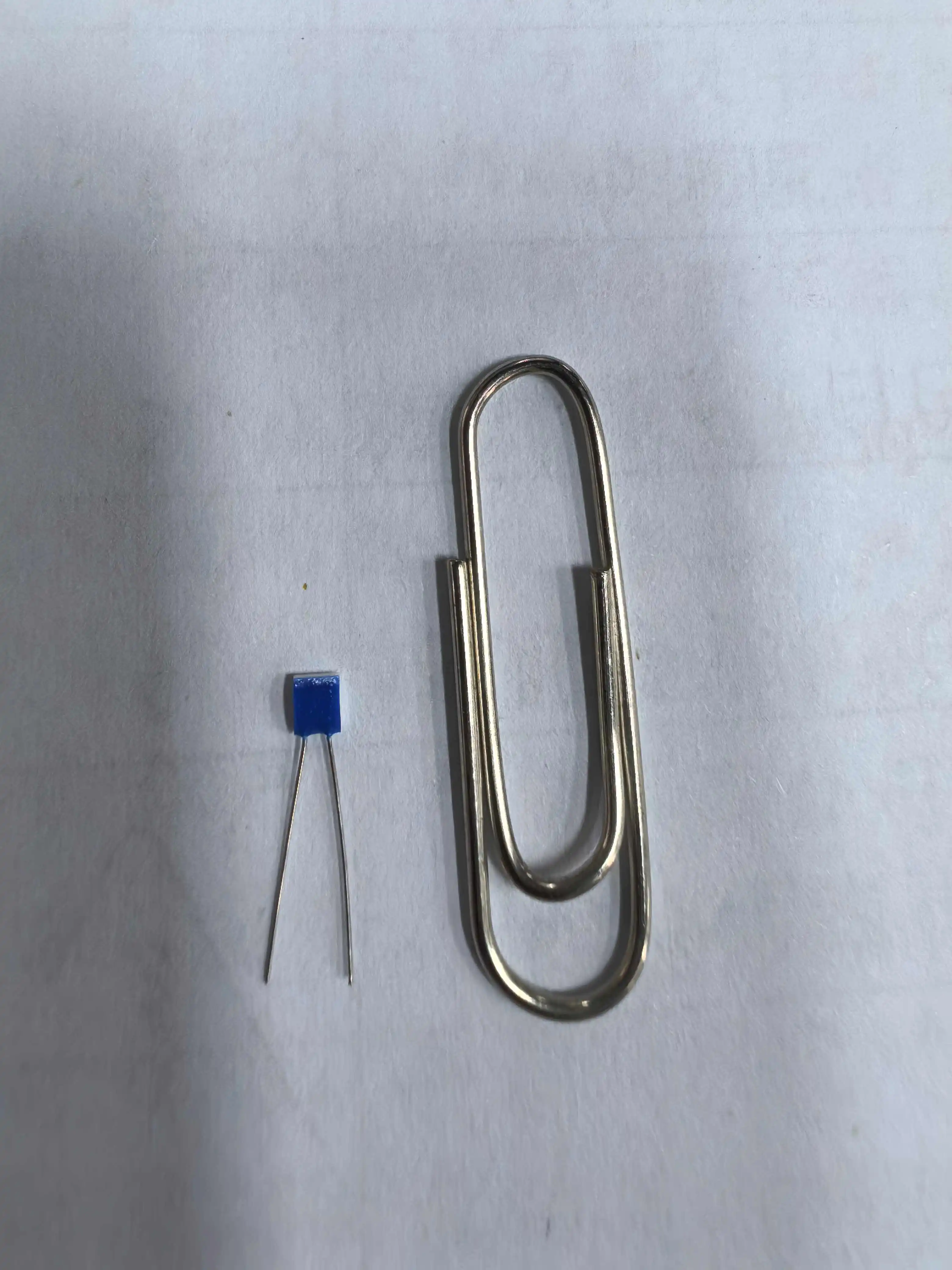

Modern Pt100 sensors often employ thin-film technology, where a precise layer of platinum is deposited onto a ceramic substrate. This construction method allows for miniaturization while maintaining high accuracy. Typical dimensions for these sensing elements can range from 1.2mm x 2.0mm x 1.0mm to 2.0mm x 2.3mm x 1.0mm, depending on the specific application requirements.

The thin-film design offers several advantages:

- Rapid response time: With a flow response time (t0.5) as low as 0.05 seconds, these sensors can detect temperature changes quickly.

- Vibration resistance: Capable of withstanding accelerations of 40g or more in the 10 to 2000 Hz frequency range.

- Shock resistance: Engineered to endure shock loads of 100g acceleration or higher.

These features make Pt100 sensors suitable for use in dynamic environments where rapid temperature fluctuations and mechanical stresses are common.

Performance Characteristics of Pt100 Sensors

The reliability of Pt100 sensors is further evidenced by their impressive performance characteristics, which are critical for maintaining accuracy in diverse applications.

Temperature Coefficient and Accuracy

Pt100 sensors are characterized by a temperature coefficient of resistance (TCR) of 3850 ppm/°C. This standardized value, compliant with the IEC60751 standard, ensures consistency across different sensor manufacturers and simplifies integration into measurement systems.

The accuracy of Pt100 sensors can be remarkably high, with some high-precision models offering accuracies of ±0.01 Ω. This translates to temperature measurement precision on the order of hundredths of a degree Celsius, making Pt100 sensors suitable for applications requiring extreme accuracy.

Long-Term Stability and Drift

One of the most crucial aspects of sensor reliability is long-term stability. Pt100 sensors excel in this regard, with typical long-term stability specifications of ≤±0.04% resistance drift after 1000 hours of operation at 500°C. This exceptional stability ensures that calibration intervals can be extended, reducing maintenance costs and improving overall system reliability.

Operating Range and Environmental Resilience

Pt100 sensors boast an impressive operating temperature range, typically from -200°C to +850°C. This wide range makes them versatile for use in cryogenic applications, industrial processes, and high-temperature environments.

The environmental resilience of Pt100 sensors is further enhanced by their high insulation resistance, which can be 100 MΩ at 20°C and remain above 2 MΩ even at elevated temperatures of 500°C. This characteristic ensures electrical isolation and measurement integrity across a broad temperature spectrum.

Applications and Innovations in Pt100 Sensor Technology

The reliability and versatility of Pt100 temperature sensing elements have led to their widespread adoption across various industries and continue to drive innovations in sensor design and application.

Industrial and Scientific Applications

Pt100 sensors find extensive use in industrial processes where precise temperature control is critical. Some key applications include:

- Pharmaceutical manufacturing: Ensuring consistent temperatures during drug production and storage.

- Food and beverage industry: Monitoring cooking, pasteurization, and refrigeration processes.

- Aerospace: Measuring engine temperatures and environmental conditions in aircraft.

- Semiconductor fabrication: Controlling temperatures in wafer processing and chip manufacturing.

- Laboratory equipment: Providing accurate temperature readings for scientific research and quality control.

In these applications, the long-term stability and wide temperature range of Pt100 sensors are particularly valuable, allowing for consistent performance in critical processes.

Advancements in Sensor Design

Ongoing research and development in Pt100 sensor technology continue to push the boundaries of performance and reliability. Some recent innovations include:

- Miniaturization: Development of ultra-small sensors for applications in microelectronics and medical devices.

- Enhanced vibration resistance: Improved designs capable of withstanding extreme mechanical stresses in automotive and aerospace applications.

- Self-calibrating sensors: Integration of smart electronics for in-situ calibration and drift compensation.

- Multi-sensor arrays: Combining multiple Pt100 elements for distributed temperature sensing in large systems.

These advancements are expanding the applicability of Pt100 sensors to new frontiers, including Internet of Things (IoT) devices and smart manufacturing systems.

Customization and Specialized Solutions

The versatility of Pt100 Temperature Sensing Element sensor technology allows for extensive customization to meet specific application requirements. Manufacturers offer a range of options, including:

- Various lead materials: Platinum-nickel, silver-palladium, or silver-nickel wires to suit different environmental conditions.

- Custom dimensions: Tailored sensor sizes for space-constrained applications.

- Specialized packaging: Encapsulation options for harsh environments or sanitary requirements.

- Integrated signal conditioning: Built-in amplifiers or transmitters for direct integration with control systems.

This flexibility ensures that Pt100 sensors can be optimized for reliability and performance in virtually any temperature measurement scenario.

Conclusion

The reliability of Pt100 sensors stems from the unique properties of platinum combined with advanced sensor design and manufacturing techniques. Their accuracy, stability, and versatility make them indispensable in a wide range of applications, from industrial processes to cutting-edge scientific research. As technology continues to advance, Pt100 temperature sensing elements are likely to remain at the forefront of precision temperature measurement, adapting to new challenges and expanding into emerging fields.

For more information on state-of-the-art Pt100 sensors and customized temperature measurement solutions, please contact our team of experts at sales11@xatzd.com. Our commitment to quality and innovation ensures that you'll find the perfect temperature sensing solution for your specific needs.