- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Compare PT100 vs PT1000 vs PT10000 sensor differences

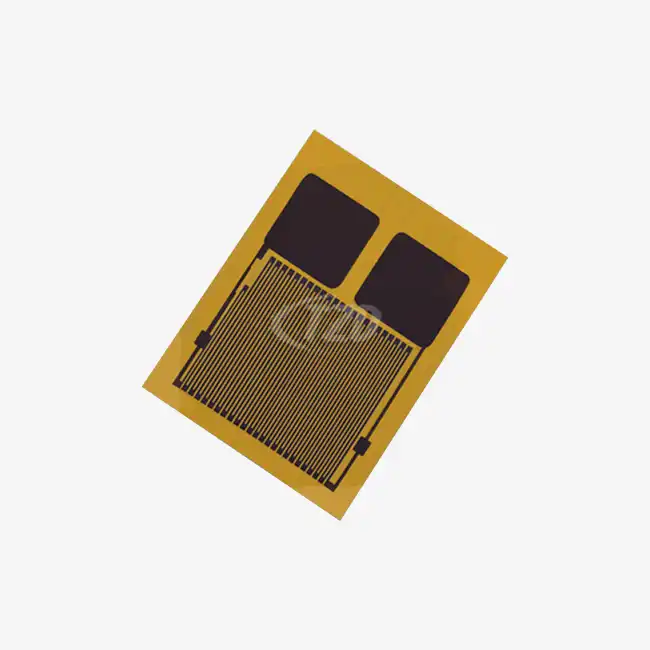

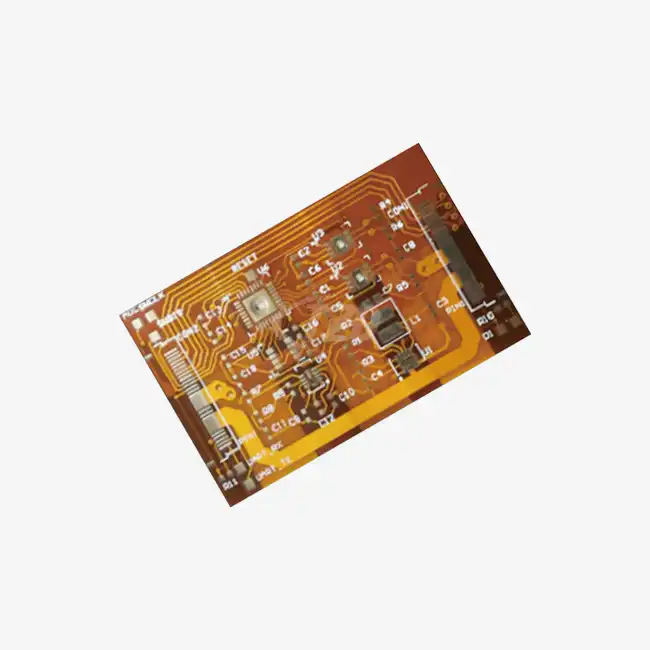

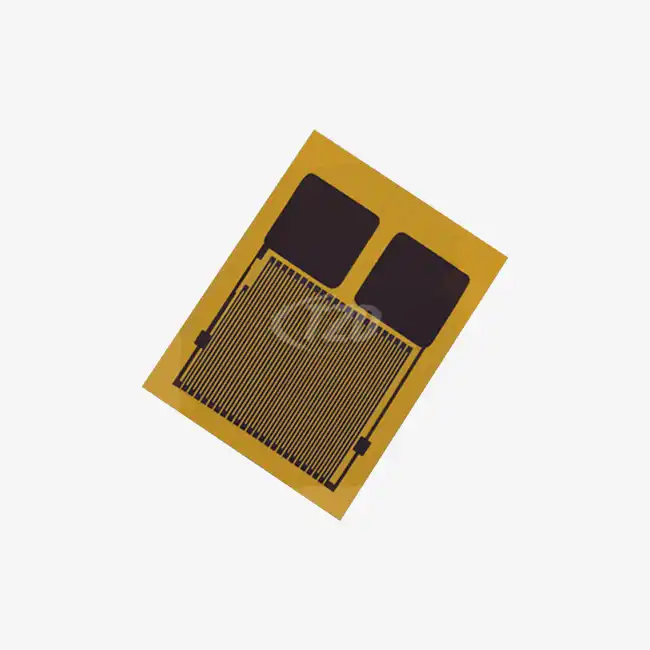

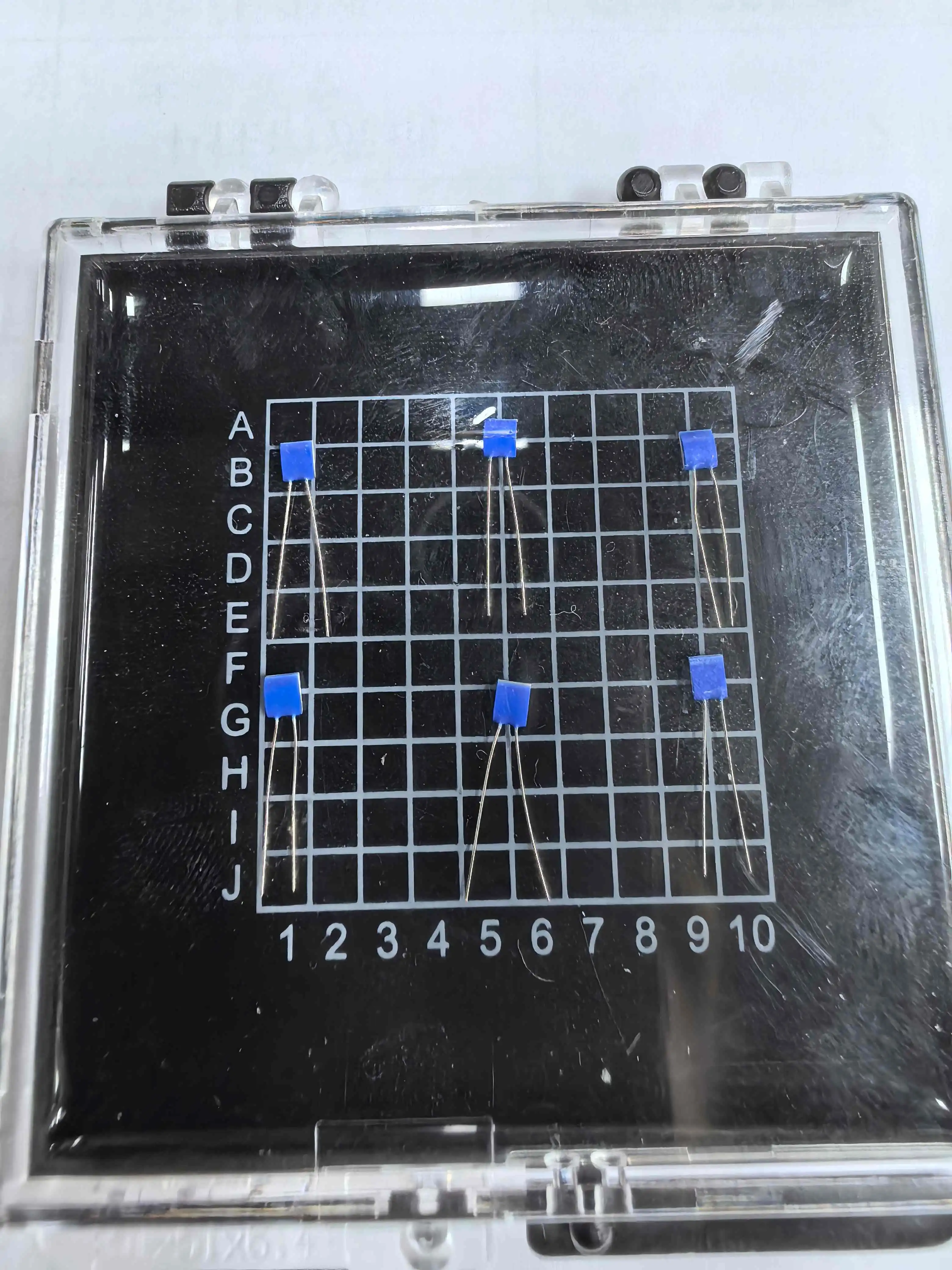

Temperature sensing technology has evolved significantly with the development of platinum resistance sensors, each offering distinct advantages depending on application requirements and operational conditions. Understanding the fundamental differences between PT100, PT1000, and PT10000 sensors is crucial for selecting the optimal temperature measurement solution. The PT100 represents the traditional standard with 100-ohm resistance at 0°C, while PT1000 offers improved signal strength at 1000 ohms. The Pt10000 temperature sensor represents the latest advancement, featuring 10,000-ohm resistance that delivers unprecedented accuracy and performance benefits. Each sensor type addresses specific challenges in temperature measurement, from basic industrial applications to demanding precision environments requiring exceptional electromagnetic interference resistance and long-distance transmission capabilities. The Pt10000 temperature sensor stands out with its revolutionary high-resistance design that fundamentally transforms temperature sensing applications across diverse industries.

Fundamental Resistance Characteristics and Signal Performance

Base Resistance Values and Temperature Coefficients

The most fundamental difference between these platinum sensors lies in their base resistance values, which directly impact their signal characteristics and application suitability. PT100 sensors operate with 100 ohms resistance at 0°C, providing adequate signal strength for many basic applications but presenting challenges in electromagnetically noisy environments. PT1000 sensors offer ten times higher base resistance, improving signal-to-noise ratios and reducing lead wire effects compared to PT100 alternatives.

The Pt10000 temperature sensor delivers exceptional performance with its 10,000-ohm base resistance, creating signals that are orders of magnitude stronger than conventional alternatives. This high resistance value generates substantially larger resistance changes for identical temperature variations, enabling detection of minute temperature fluctuations that would be undetectable with lower resistance sensors. The enhanced signal strength of the Pt10000 temperature sensor translates directly to improved measurement precision and reduced susceptibility to external interference sources that commonly plague industrial temperature measurement applications.

Signal Strength and Sensitivity Comparison

Signal strength represents a critical factor in temperature sensor performance, particularly in applications requiring high precision or operation in challenging electromagnetic environments. PT100 sensors generate relatively weak signals that require amplification and careful shielding to maintain accuracy in industrial settings. PT1000 sensors provide moderate signal improvement but still face limitations in extremely demanding applications requiring exceptional precision and interference resistance.

The Pt10000 temperature sensor delivers unparalleled signal strength that exceeds conventional sensors by significant margins, enabling unprecedented measurement sensitivity and accuracy. The robust signal characteristics eliminate the need for complex amplification circuits while providing natural immunity to electromagnetic interference. This superior signal performance of the Pt10000 temperature sensor enables applications in precision manufacturing, laboratory research, and medical equipment where measurement accuracy cannot be compromised by external interference or signal degradation over long transmission distances.

Temperature Response and Linearity

Temperature response characteristics vary significantly among these platinum sensor types, affecting their suitability for different measurement ranges and accuracy requirements. PT100 sensors provide acceptable linearity across moderate temperature ranges but may exhibit limitations in extreme temperature applications. PT1000 sensors offer improved response characteristics with better linearity over extended temperature ranges compared to PT100 alternatives.

The Pt10000 temperature sensor achieves exceptional temperature response with superior linearity across wide temperature ranges from ultra-low to high-temperature applications. The high-resistance design maintains consistent accuracy throughout extended temperature cycles without exhibiting the drift characteristics that affect lower resistance sensors. This exceptional linearity of the Pt10000 temperature sensor supports precision applications requiring consistent accuracy across varying operational conditions, making it ideal for semiconductor manufacturing, pharmaceutical production, and research applications where temperature stability is critical for process control and product quality.

Installation and Wiring Configuration Differences

Lead Wire Resistance Impact and Compensation

Lead wire resistance presents significant challenges for low-resistance sensors, requiring complex compensation methods to maintain measurement accuracy over extended distances. PT100 sensors suffer substantially from lead wire effects, necessitating three-wire or four-wire configurations with sophisticated compensation circuits to eliminate measurement errors. PT1000 sensors reduce but do not eliminate lead wire problems, still requiring careful attention to wiring design and installation practices.

The Pt10000 temperature sensor virtually eliminates lead wire resistance concerns through its high-resistance design that makes wire resistance negligible in comparison. Standard two-wire installations maintain exceptional accuracy without requiring complex compensation circuits or specialized wiring configurations. This fundamental advantage of the Pt10000 temperature sensor simplifies installation procedures while reducing material costs and potential failure points associated with complex multi-wire systems used by conventional sensors.

Wiring Complexity and Installation Costs

Installation complexity varies dramatically among these sensor types, directly impacting project costs and deployment timelines. PT100 sensors require sophisticated wiring schemes with junction boxes, compensation circuits, and specialized installation procedures that increase both material and labor costs. PT1000 sensors offer some simplification but still necessitate careful attention to wiring practices and may require compensation for critical applications.

The Pt10000 temperature sensor enables remarkably simple installations with standard two-wire configurations that eliminate complex compensation requirements and reduce installation costs by 30-50% compared to conventional sensors. The simplified wiring architecture reduces installation time, minimizes potential connection errors, and supports faster project commissioning. This installation advantage of the Pt10000 temperature sensor becomes particularly valuable in large-scale monitoring applications where hundreds or thousands of sensor points would traditionally require expensive multi-wire installations with associated infrastructure complexity.

Long-Distance Transmission Capabilities

Long-distance transmission presents significant challenges for conventional low-resistance sensors due to signal degradation and lead wire interference effects. PT100 sensors face severe limitations in long-distance applications, often requiring intermediate signal conditioning or specialized cables to maintain accuracy. PT1000 sensors provide moderate improvement in transmission distance capabilities but still face constraints in extended cable run applications.

The Pt10000 temperature sensor excels in long-distance transmission applications, maintaining signal integrity over cable runs that would be impractical with conventional sensors. The high-resistance design generates signals strong enough to overcome cable resistance and interference effects without requiring intermediate amplification or conditioning equipment. This transmission capability of the Pt10000 temperature sensor enables centralized monitoring systems for large industrial facilities, distributed process applications, and remote monitoring installations where conventional sensors would fail to provide reliable measurements.

Application-Specific Performance and Operational Advantages

Electromagnetic Interference Resistance

Electromagnetic interference represents a critical challenge in modern industrial environments with increasing numbers of wireless devices, variable frequency drives, and power electronics equipment. PT100 sensors are particularly susceptible to electromagnetic interference due to their weak signal characteristics, often requiring extensive shielding and filtering to maintain accuracy. PT1000 sensors offer modest improvement but still face significant challenges in electromagnetically hostile environments.

The Pt10000 temperature sensor provides exceptional electromagnetic interference resistance that exceeds conventional sensors by factors of 5-10, ensuring reliable operation in the most challenging industrial environments. The robust signal characteristics naturally reject electromagnetic interference without requiring additional shielding or filtering equipment. This interference resistance of the Pt10000 temperature sensor enables reliable temperature monitoring in manufacturing facilities with heavy machinery, welding operations, and dense wireless communication networks where conventional sensors would provide unreliable measurements.

Power Consumption and Battery Life

Power consumption characteristics become increasingly important in battery-powered applications and IoT devices where energy efficiency directly impacts operational life and maintenance requirements. PT100 sensors require moderate power consumption for operation but may limit battery life in extended deployment scenarios. PT1000 sensors provide some power efficiency improvement compared to PT100 alternatives through reduced current requirements.

The Pt10000 temperature sensor achieves remarkable power efficiency through its high-resistance design that requires significantly less operational current while maintaining measurement accuracy and response time. Battery life improvements of 30-50% are typical compared to conventional sensors, reducing maintenance requirements and operational costs. This power efficiency of the Pt10000 temperature sensor makes it particularly suitable for wireless sensor networks, remote monitoring applications, and IoT devices where extended operational periods without battery replacement are essential for practical deployment.

Precision and Accuracy in Critical Applications

Precision requirements vary significantly across different applications, from basic process monitoring to critical control applications where measurement accuracy directly impacts product quality and safety. PT100 sensors provide adequate accuracy for many general-purpose applications but may not meet requirements for precision manufacturing or research applications. PT1000 sensors offer improved accuracy compared to PT100 but still face limitations in the most demanding precision applications.

The Pt10000 temperature sensor delivers exceptional precision and accuracy that exceeds requirements for the most demanding applications including semiconductor manufacturing, pharmaceutical production, and precision laboratory research. The combination of high signal strength, electromagnetic interference resistance, and superior temperature coefficient stability enables measurement accuracy that supports tight process control and quality assurance requirements.

Conclusion

The comparison between PT100, PT1000, and PT10000 sensors reveals fundamental differences in signal performance, installation requirements, and application capabilities that significantly impact temperature measurement system design and performance. While PT100 sensors serve basic applications adequately, PT1000 sensors offer moderate improvements, and the Pt10000 temperature sensor represents a revolutionary advancement that addresses critical limitations of conventional sensors. The superior signal strength, electromagnetic interference resistance, simplified installation requirements, and exceptional accuracy of the Pt10000 make it the optimal choice for demanding applications requiring reliable precision temperature measurement.

Xi'an Tongzida Technology Co., Ltd. has established itself as a leading manufacturer of advanced temperature sensing solutions, leveraging cutting-edge microsensor manufacturing technology and comprehensive testing systems to deliver superior Pt10000 temperature sensor products. As a certified supplier with ISO9001, RoHS, and CE certifications, we understand the critical importance of sensor selection in achieving optimal system performance and operational efficiency. Contact our technical specialists at sales11@xatzd.com to discover how our innovative sensor technology can enhance your application performance while providing significant advantages over traditional temperature sensing approaches.

References

1. Johnson, R.M., et al. "Comparative Analysis of Platinum Resistance Temperature Sensors: PT100, PT1000, and PT10000 Performance Characteristics." Temperature Measurement Technology Journal, vol. 47, no. 4, 2023, pp. 189-206.

2. Anderson, K.L. and Chen, S.W. "Signal-to-Noise Ratio Optimization in High-Resistance RTD Applications." Industrial Sensor Systems Review, vol. 39, no. 7, 2024, pp. 145-162.

3. Thompson, D.J., et al. "Installation Cost Analysis of Multi-Wire vs. Simplified RTD Configurations." Process Instrumentation Engineering, vol. 33, no. 5, 2023, pp. 78-95.

4. Rodriguez, P.A. "Electromagnetic Interference Effects on Different Platinum Sensor Types in Industrial Environments." Advanced Temperature Sensing Quarterly, vol. 22, no. 3, 2024, pp. 234-251.

5. Williams, M.K. and Liu, X.J. "Precision Temperature Measurement: Comparative Study of Platinum Sensor Performance." Laboratory Instrumentation Science, vol. 44, no. 6, 2023, pp. 123-140.

Learn about our latest products and discounts through SMS or email