The Evolution and Advantages of Thin Film Sensor Technology

From Traditional Sensors to Cutting-Edge Thin Film Technology

The journey of sensor technology has been marked by continuous innovation and improvement. Traditional sensors, while effective, often faced limitations in terms of size, accuracy, and response time. The advent of thin film sensor technology, exemplified by the Pt300 Thin Film Sensor, has addressed many of these challenges, ushering in a new era of sensing capabilities.

Thin film sensors are fabricated using advanced deposition techniques, allowing for the creation of extremely thin and precise sensing elements. This process enables the production of sensors with remarkable characteristics, including enhanced sensitivity, faster response times, and improved stability. The Pt300 Thin Film Sensor, for instance, utilizes platinum as its sensing element, known for its excellent temperature coefficient and stability over a wide temperature range.

Key Advantages of Advanced Thin Film Sensors

The adoption of thin film sensor technology offers several significant advantages over conventional sensing methods:

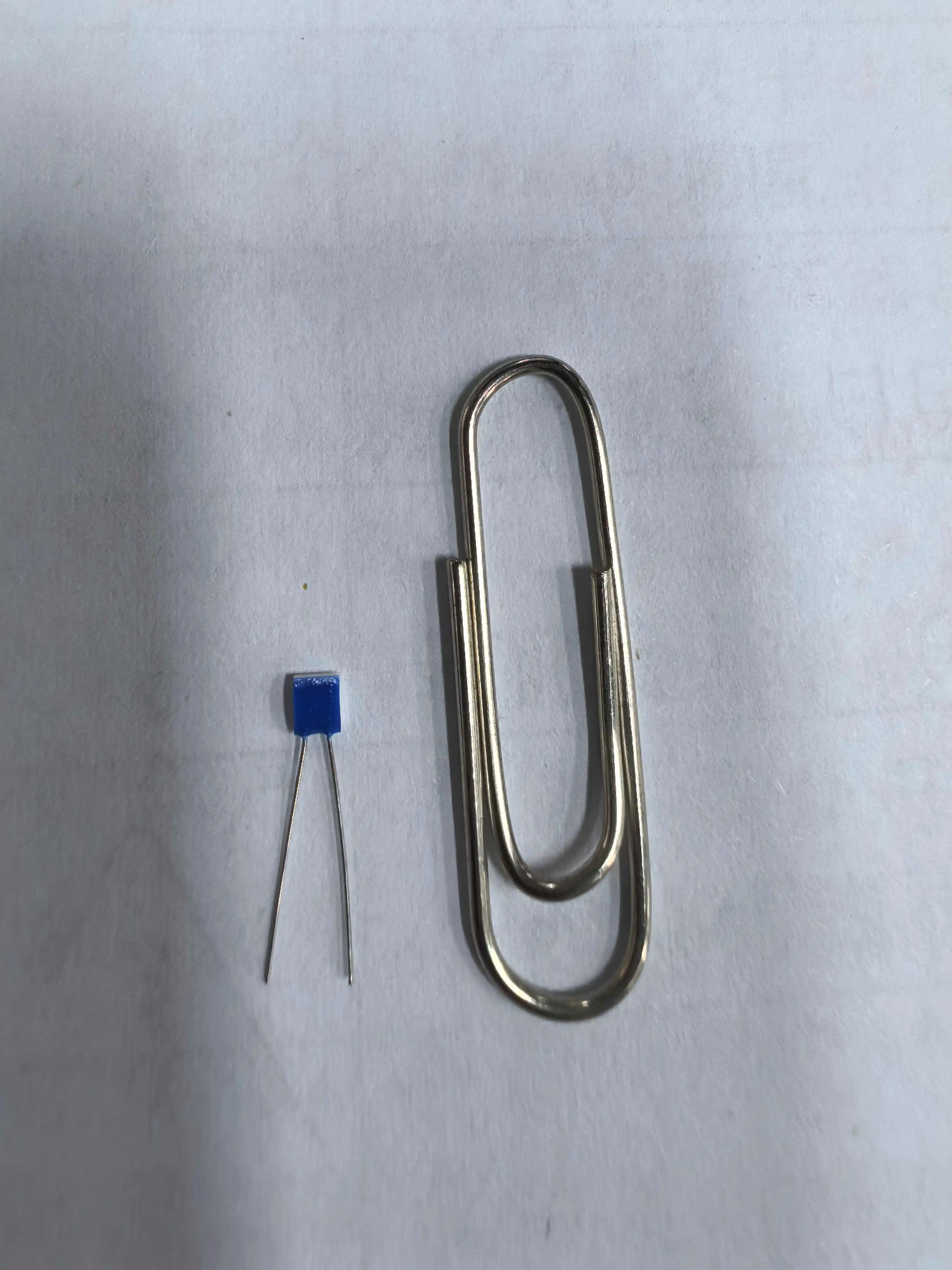

- Miniaturization: Thin film sensors can be produced in extremely small sizes, making them ideal for applications where space is at a premium. The ability to create sensors as small as 1.2mm opens up new possibilities for integration into compact devices and systems.

- High Accuracy: With an accuracy of ± 0.01 Ω, thin film sensors like the Pt300 provide exceptionally precise measurements, crucial for applications requiring high levels of control and monitoring.

- Wide Temperature Range: Advanced thin film sensors can operate across an impressive temperature spectrum, from -200°C to +850°C, making them suitable for diverse environments and applications.

- Rapid Response: The thin nature of the sensing element allows for quick heat transfer, resulting in response times as fast as 0.05 seconds. This rapid response is essential in applications where real-time data is critical.

- Durability: Despite their delicate construction, thin film sensors exhibit remarkable durability. With vibration resistance of 40g and impact resistance of 100g, they can withstand harsh industrial environments and challenging conditions.

These advantages make thin film sensors, particularly the Pt300 Thin Film Sensor, indispensable in various high-demand scenarios across multiple industries.

Applications and Impact of Advanced Thin Film Sensors

Industrial Applications: Enhancing Efficiency and Control

In the industrial sector, advanced thin film sensors are transforming manufacturing processes and quality control measures. The Pt300 Thin Film Sensor, with its high accuracy and rapid response time, enables precise temperature control in critical industrial processes. This level of control leads to improved product quality, reduced waste, and enhanced energy efficiency.

For instance, in semiconductor manufacturing, where temperature control is paramount, thin film sensors provide the necessary precision to maintain optimal conditions during wafer processing. Similarly, in chemical and pharmaceutical industries, these sensors ensure accurate temperature monitoring during reactions and storage, contributing to product consistency and safety.

Medical and Healthcare: Advancing Patient Care

The medical field has seen significant advancements with the integration of thin film sensor technology. The miniature size and high accuracy of sensors like the Pt300 make them ideal for various medical devices and diagnostic equipment. From advanced thermometers to sophisticated imaging systems, thin film sensors are enhancing the capabilities of medical technology.

In applications such as blood analysis equipment, these sensors provide rapid and accurate temperature measurements, crucial for reliable test results. Additionally, their use in medical implants and wearable health monitoring devices is opening new avenues for continuous patient monitoring and personalized healthcare.

Automotive and Aerospace: Driving Safety and Performance

The automotive and aerospace industries are leveraging the capabilities of advanced thin film sensors to enhance vehicle safety, performance, and efficiency. In automotive applications, these sensors play a vital role in engine management systems, exhaust gas recirculation, and battery temperature monitoring in electric vehicles.

The aerospace sector benefits from the wide temperature range and high reliability of thin film sensors. They are crucial components in aircraft engine monitoring systems, helping to ensure optimal performance and safety. The sensors' ability to withstand extreme conditions makes them invaluable in space exploration missions, where they provide critical data on spacecraft systems and environmental conditions.

Future Prospects and Emerging Trends in Thin Film Sensor Technology

Integration with IoT and AI

The future of thin film sensor technology is closely tied to the growth of the Internet of Things (IoT) and artificial intelligence (AI). As these technologies continue to evolve, the integration of advanced sensors like the Pt300 Thin Film Sensor will become increasingly important. These sensors will serve as the primary data collection points for IoT networks, providing the high-quality, real-time data necessary for AI-driven decision-making and predictive analytics.

In smart manufacturing environments, for example, networks of thin film sensors will enable comprehensive monitoring of production processes, leading to predictive maintenance, optimized energy usage, and enhanced product quality. The combination of sensor data with AI algorithms will allow for unprecedented levels of automation and efficiency in industrial operations.

Advancements in Materials and Fabrication Techniques

Ongoing research in materials science and fabrication techniques promises to further enhance the capabilities of thin film sensors. New materials with improved temperature coefficients and stability are being developed, potentially expanding the operating range and accuracy of these sensors even further.

Advancements in nanotechnology and microfabrication techniques are also opening up new possibilities for sensor design. These developments may lead to even smaller sensors with improved performance characteristics, enabling their integration into an even wider range of applications and devices.

Expanding Applications in Emerging Fields

As thin film sensor technology continues to advance, its applications are expanding into new and emerging fields. In renewable energy, these sensors are playing a crucial role in optimizing the performance of solar panels and wind turbines. In environmental monitoring, they are enabling more accurate and widespread tracking of climate conditions and pollution levels.

The field of robotics is another area where thin film sensors are making significant contributions. Their small size and high accuracy make them ideal for integration into robotic systems, enhancing their sensory capabilities and enabling more sophisticated interactions with their environment.

Conclusion

Advanced thin film sensor technology, exemplified by products like the Pt300 Thin Film Sensor, is undeniably shaping the future across multiple industries. Its combination of miniaturization, high accuracy, wide temperature range, and durability is enabling innovations that were previously unattainable. As we look to the future, the continued development and integration of this technology promise to drive further advancements in automation, healthcare, transportation, and beyond.

The potential applications of thin film sensors are vast and continually expanding. From improving industrial processes to enhancing patient care and pushing the boundaries of space exploration, these sensors are at the forefront of technological progress. As research continues and new applications emerge, the impact of thin film sensor technology on our daily lives and various industries is set to grow exponentially.

For those interested in exploring the possibilities of advanced thin film sensor technology or seeking customized solutions for specific applications, Xi'an Tongzida Technology Co., Ltd. offers expertise and innovation in this field. To learn more about their range of thin film sensors, including the Pt300 Thin Film Sensor, and how they can benefit your projects, please contact their sales team at sales11@xatzd.com.