Understanding Pt100 Sensors and Their Customization Potential

The Basics of Pt100 Sensors

Pt100 sensors are platinum resistance thermometers that leverage the principle of resistance change with temperature. These sensors are renowned for their accuracy, stability, and wide temperature measurement range. The "Pt" in Pt100 stands for platinum, while "100" indicates a resistance of 100 ohms at 0°C. As temperature increases, the resistance of the platinum element rises in a predictable and repeatable manner.

Standard Pt100 sensors comply with IEC60751, featuring a temperature coefficient of 3850 ppm/°C. This coefficient ensures consistent performance across various temperature ranges, typically from -200°C to +850°C. The accuracy of these sensors can reach ±0.01 Ω, making them ideal for applications requiring precise temperature measurements.

Customization Options for Pt100 Sensors

Customization of Pt100 sensors opens up a world of possibilities for optimizing temperature measurement in specific applications. Some key customization options include:

- Element Dimensions: Sensors can be tailored to various sizes, ranging from 1.2mm to 4.0mm, to fit space-constrained applications.

- Temperature Range: While standard Pt100 sensors cover a broad range, customized versions can be optimized for narrower, application-specific ranges.

- Lead Materials: Options include platinum nickel, silver nickel, or pure platinum, each offering unique benefits for different environments.

- Packaging: Custom packaging can enhance durability, chemical resistance, or compatibility with specific mounting requirements.

- Response Time: Specialized designs can achieve response times as low as 0.05 seconds for rapid temperature detection.

Advanced Manufacturing Techniques

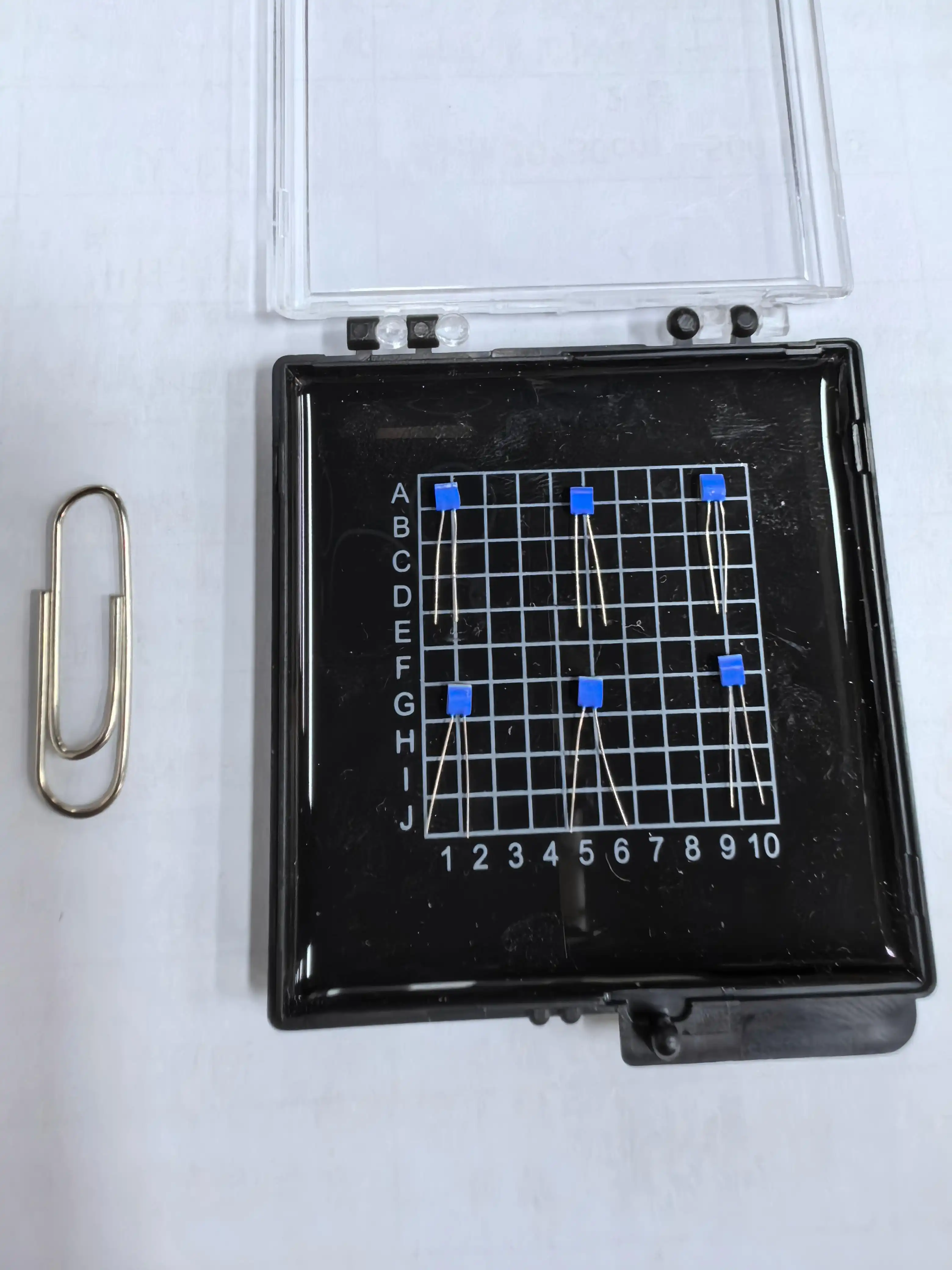

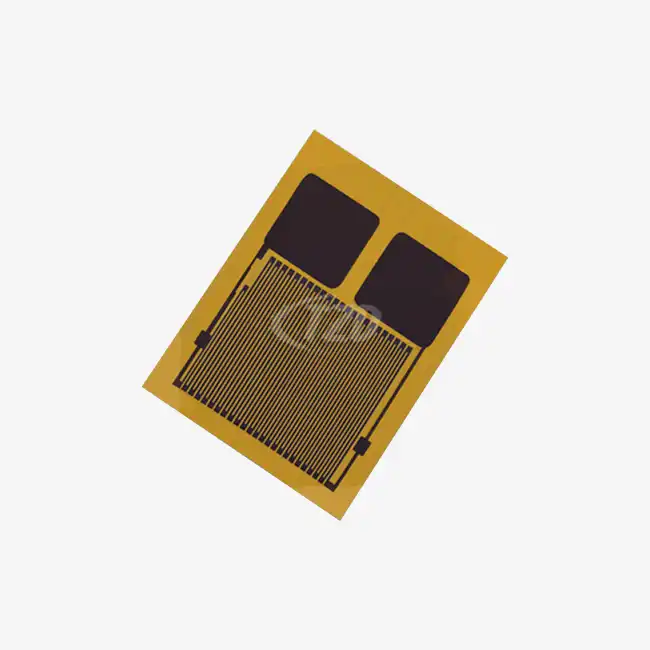

Modern Pt100 sensor customization utilizes advanced thin-film technology. This process involves depositing a precise layer of platinum on a ceramic substrate, allowing for miniaturization and improved performance. Automated production lines ensure consistency and quality in the manufacturing of these customized sensors.

For instance, SMD (Surface Mount Device) thin-film platinum resistance thermistors can be produced with dimensions as compact as 3.2mm x 1.6mm x 0.7mm. These sensors maintain excellent stability, with resistance drift of R₀°C not exceeding ±0.06% after 1000 hours at 200°C.

Benefits of Customizing Pt100 Sensors for Specific Applications

Enhanced Accuracy and Precision

Customized Pt100 sensors can be fine-tuned to deliver superior accuracy within specific temperature ranges. By optimizing the sensor design for a narrower range, manufacturers can achieve tighter tolerances and more precise measurements. This enhanced accuracy is crucial in applications such as semiconductor manufacturing, where even minor temperature fluctuations can significantly impact product quality.

Improved Response Time

Through customization, Pt100 sensors can be engineered to respond more quickly to temperature changes. This is particularly valuable in processes requiring rapid temperature control or in safety-critical applications where swift detection of temperature anomalies is essential. Customized sensors with response times as low as 0.05 seconds enable real-time temperature monitoring and control in dynamic environments.

Durability and Longevity

Tailoring Pt100 sensors to specific environmental conditions can significantly enhance their durability and longevity. For instance, sensors designed for high-vibration environments can incorporate reinforced construction to withstand up to 40g of vibration and 100g of impact. This ruggedness ensures reliable operation and reduced maintenance needs in harsh industrial settings or aerospace applications.

Compatibility with Specific Processes

Customized Pt100 sensors can be designed to seamlessly integrate with existing processes or equipment. This might involve creating sensors with specific mounting options, connector types, or output signals that align perfectly with the user's systems. Such compatibility streamlines installation, reduces integration challenges, and minimizes the risk of errors in temperature measurement.

Industries Benefiting from Customized Pt100 Sensors

Aerospace and Aviation

The aerospace industry demands sensors capable of withstanding extreme temperatures, vibrations, and rapid pressure changes. Customized Pt100 sensors can be engineered to meet these rigorous requirements, ensuring accurate temperature monitoring in aircraft engines, hydraulic systems, and avionics. The ability to withstand high g-forces and maintain accuracy over a wide temperature range makes these sensors indispensable in ensuring flight safety and efficiency.

Medical and Pharmaceutical

In medical applications, precision and reliability are paramount. Customized Pt100 sensors can be designed to meet stringent sterilization requirements and offer the necessary biocompatibility for use in medical devices. From monitoring body temperature in critical care settings to ensuring precise temperature control in pharmaceutical manufacturing processes, these tailored sensors play a crucial role in maintaining quality and safety standards.

Automotive Industry

The automotive sector benefits from customized Pt100 sensors in various applications, including engine temperature monitoring, battery management in electric vehicles, and climate control systems. Sensors designed to withstand the harsh environments found in vehicles, such as high temperatures and constant vibrations, ensure reliable performance and contribute to improved vehicle efficiency and safety.

Industrial Process Control

In industrial settings, customized Pt100 sensors find applications in a wide range of processes, from food and beverage production to chemical manufacturing. These sensors can be tailored to resist corrosive environments, withstand high pressures, or operate in explosive atmospheres. The ability to customize sensors for specific industrial processes leads to improved product quality, enhanced energy efficiency, and reduced downtime.

Research and Development

Scientific research often requires temperature measurements under unique or extreme conditions. Customized Pt100 sensors can be designed to operate in ultra-low temperatures, vacuum environments, or in the presence of strong electromagnetic fields. This flexibility allows researchers to obtain accurate temperature data in experimental setups that would be challenging or impossible with standard sensors.

Conclusion

Customizing Pt100 sensors offers a myriad of benefits across various industries, from aerospace to medical and industrial applications. By tailoring these sensors to specific needs, businesses can achieve higher accuracy, improved reliability, and enhanced performance in their temperature measurement systems. The ability to optimize sensor characteristics such as size, temperature range, and response time allows for seamless integration into diverse applications, ultimately leading to improved processes and products.

As technology continues to advance, the potential for customization in Pt100 sensors grows, opening new possibilities for innovative temperature measurement solutions. For those seeking to leverage the benefits of customized Pt100 sensors in their applications, it's crucial to partner with experienced manufacturers who possess the expertise and advanced manufacturing capabilities required to deliver high-quality, tailored solutions.

To explore how customized Pt100 sensors can benefit your specific application or to learn more about our advanced thin-film platinum resistor technology, please contact us at sales11@xatzd.com. Our team of experts is ready to assist you in developing the perfect temperature measurement solution for your unique requirements.