The Technology Behind Flexible Thin Film Temperature Sensors

Advanced Materials and Manufacturing Processes

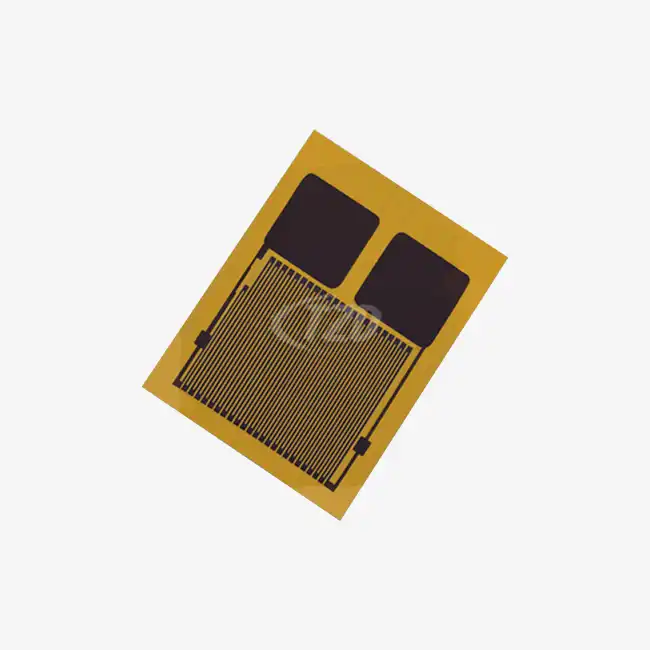

Flexible thin film temperature sensors represent a pinnacle of modern sensor technology, combining cutting-edge materials science with precision manufacturing techniques. These sensors typically utilize platinum as the primary sensing element, deposited in an ultra-thin layer on a flexible substrate. The platinum layer, often just a few nanometers thick, is carefully engineered to achieve a specific electrical resistance that changes predictably with temperature.

The manufacturing process involves advanced techniques such as sputtering or chemical vapor deposition to create the platinum film. This process ensures uniformity and stability of the sensing element, critical for achieving high accuracy and long-term reliability. The substrate material is chosen for its flexibility and thermal properties, often utilizing polyimide or other high-performance polymers that can withstand a wide range of temperatures without degradation.

Precision Design for Optimal Performance

The design of flexible thin film temperature sensors is a delicate balance of various factors. The sensor's geometry, including the thickness and pattern of the platinum film, is optimized to achieve the desired temperature coefficient of resistance (TCR). This coefficient, typically around 3850 ppm/°C for platinum sensors, determines the sensor's sensitivity to temperature changes.

Engineers also focus on minimizing self-heating effects, where the electrical current used to measure resistance causes a slight temperature increase in the sensor itself. This is achieved through careful circuit design and by using the lowest possible measurement current. Additionally, the flexible nature of these sensors requires special consideration in the design of connection points and protective coatings to ensure durability under repeated flexing and exposure to industrial environments.

Integration and Applications in Industrial Automation

Seamless Incorporation into Manufacturing Processes

The integration of flexible thin film temperature sensors into industrial automation systems is a testament to their versatility and effectiveness. These sensors can be adhered to or wrapped around various surfaces, including curved or irregular shapes, making them ideal for monitoring temperature in complex machinery or hard-to-reach areas. This flexibility allows for non-invasive temperature measurement without disrupting the flow of processes or requiring significant modifications to existing equipment.

In automated production lines, these sensors can be strategically placed at critical points to monitor temperature changes in real-time. For instance, in plastic extrusion processes, flexible sensors can be wrapped around different zones of the extruder barrel, providing precise temperature control crucial for maintaining product quality. Similarly, in semiconductor manufacturing, where temperature control is paramount, these sensors can be integrated into wafer processing equipment to ensure uniform heating and cooling cycles.

Enhancing Precision and Efficiency in Various Industries

The application of flexible thin film temperature sensors extends across a wide range of industries, each benefiting from their unique capabilities. In the automotive industry, these sensors are used in engine management systems, battery thermal management in electric vehicles, and climate control systems. Their rapid response time, often as quick as 0.05 seconds, allows for immediate detection of temperature fluctuations, enabling swift corrective actions in automated systems.

In the food and beverage industry, these sensors play a crucial role in maintaining food safety and quality. They can be integrated into automated cooking and packaging lines, ensuring that products are processed at the correct temperatures throughout the production cycle. The sensors' ability to withstand high temperatures (up to 850°C) and their resistance to vibration (up to 40g) make them suitable for demanding food processing environments.

The aerospace industry also heavily relies on these sensors for various applications, from engine monitoring to environmental control systems in aircraft. The sensors' high accuracy (±0.01 Ω) and stability (long-term drift ≤ 0.04%) are essential for maintaining the precise conditions required in aerospace applications, where safety and reliability are paramount.

Future Trends and Innovations in Thin Film Temperature Sensing

Advancements in Sensor Miniaturization and Functionality

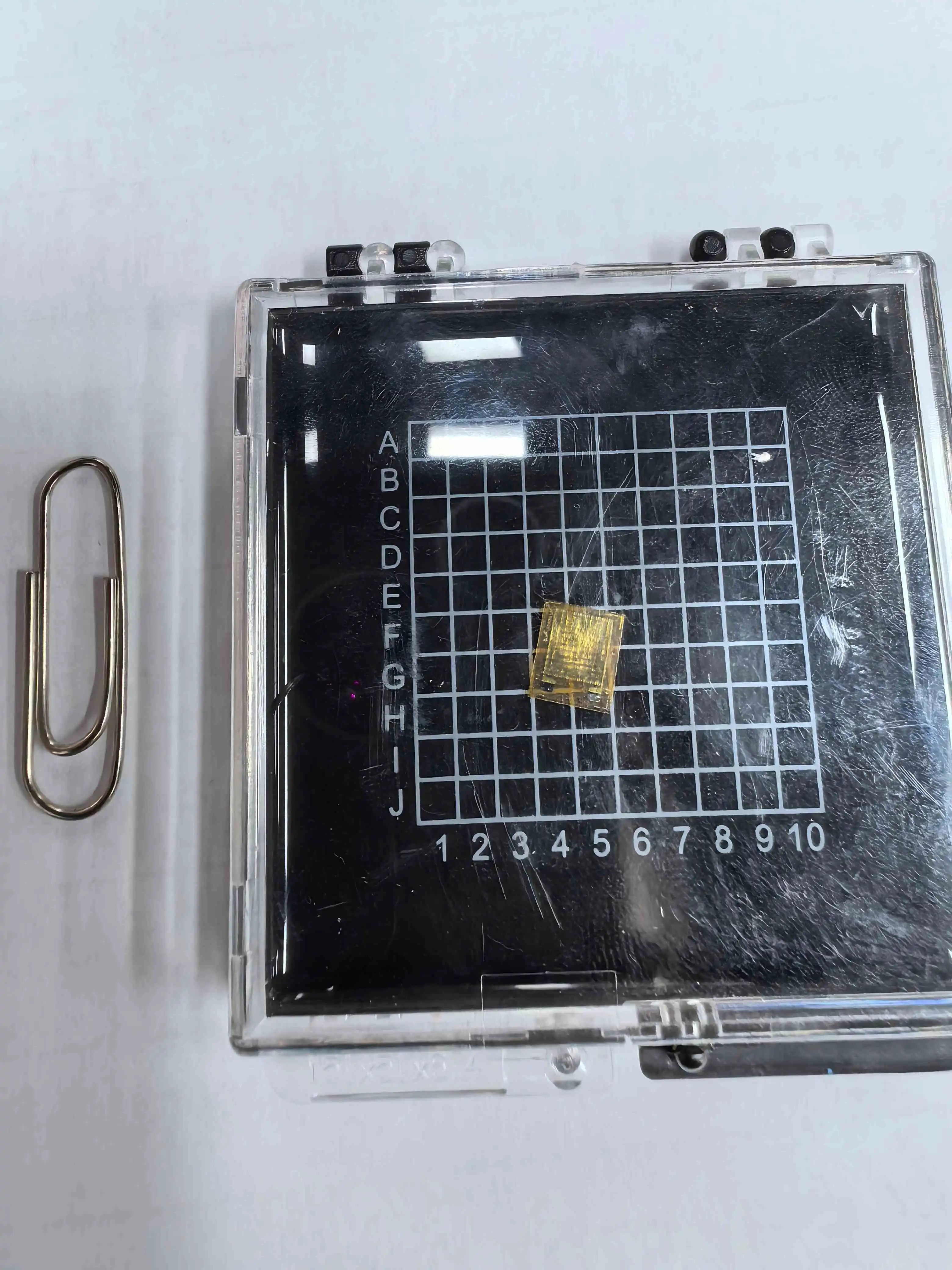

The future of flexible thin film temperature sensors is poised for significant advancements, particularly in the realm of miniaturization and enhanced functionality. Researchers are exploring ways to further reduce the size of these sensors, with some prototypes as small as 1.2mm. This miniaturization opens up new possibilities for embedding sensors in even smaller devices or more intricate machinery, expanding their application in microelectronics and nanotechnology-based industrial processes.

Additionally, there's a growing trend towards developing multi-functional sensors that can measure not only temperature but also other parameters such as pressure or humidity. This integration of multiple sensing capabilities into a single flexible thin film device could revolutionize industrial automation by providing more comprehensive data from a single sensor point, simplifying system design and reducing overall sensor footprint in complex machinery.

Integration with IoT and AI for Smarter Industrial Systems

The integration of flexible thin film temperature sensors with Internet of Things (IoT) technology is set to transform industrial automation further. By connecting these sensors to IoT networks, manufacturers can achieve real-time, remote monitoring of temperature conditions across entire production facilities. This connectivity enables more sophisticated data analysis, predictive maintenance, and automated decision-making processes.

Artificial Intelligence (AI) algorithms are being developed to work in tandem with these sensor networks, analyzing temperature data patterns to predict equipment failures, optimize energy usage, and fine-tune production processes. For instance, in smart factories, AI-powered systems could use data from flexible thin film temperature sensors to automatically adjust production parameters, ensuring optimal conditions and maximizing efficiency without human intervention.

As these technologies evolve, we can expect to see more adaptive and self-optimizing industrial systems, where flexible thin film temperature sensors serve as the critical link between the physical and digital worlds, driving the next wave of industrial automation and efficiency.

Conclusion

Flexible thin film temperature sensors have emerged as a cornerstone technology in the optimization of industrial automation. Their unique combination of precision, flexibility, and durability makes them indispensable in a wide array of applications across various industries. As we look to the future, the continued advancement of these sensors, coupled with their integration into IoT and AI systems, promises to further revolutionize industrial processes, driving unprecedented levels of efficiency, quality, and innovation.

For those seeking to leverage the power of flexible thin film temperature sensors in their industrial automation projects, Xi'an Tongzida Technology Co., Ltd. offers state-of-the-art solutions tailored to diverse industrial needs. With our advanced manufacturing capabilities and commitment to quality, we provide sensors that meet the highest standards of performance and reliability. To learn more about how our flexible thin film temperature sensors can optimize your industrial processes, please contact us at sales11@xatzd.com.