Understanding the Structure and Components of Chip Type Thermal Resistance Sensors

The Anatomy of a Chip Type Thermal Resistance Sensor

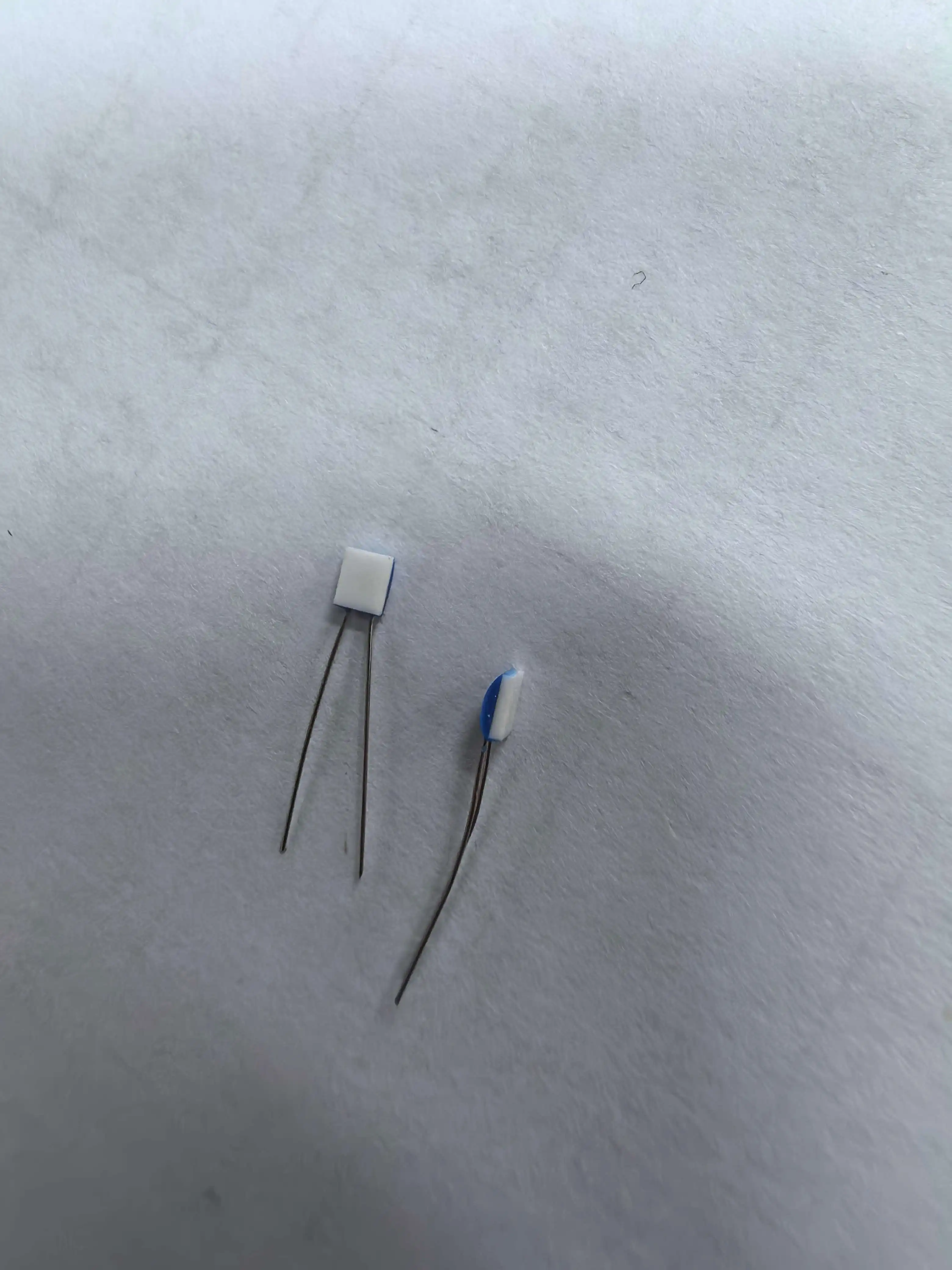

Chip type thermal resistance sensors are marvels of miniaturization and precision engineering. At their core, these sensors consist of a thin film of platinum meticulously deposited on a ceramic substrate. The dimensions of these sensors are remarkably compact, typically ranging from 1.2mm x 2.0mm x 1.0mm to 2.0mm x 2.3mm x 1.0mm. This miniature size allows for integration into a wide array of applications where space is at a premium.

The platinum film is the heart of the sensor, responsible for the actual temperature measurement. Platinum is chosen for its exceptional stability and linear resistance-temperature relationship over a wide temperature range. The film's thickness and pattern are carefully controlled to achieve the desired resistance and sensitivity characteristics.

Lead Specifications and Materials

The sensor element is connected to the outside world through leads, which are critical components in their own right. These leads typically measure 10 mm in length with a diameter of 0.2 mm, striking a balance between robustness and flexibility. The lead material is carefully selected to complement the sensor's performance. While platinum-nickel wire is a common choice, alternatives such as silver-palladium, pure platinum, or silver-nickel may be used depending on the specific application requirements.

The lead material selection is not arbitrary; it affects the sensor's overall performance and durability. For instance, the leads must withstand thermal cycling and maintain good electrical conductivity. The tensile strength of the leads is a crucial parameter, with a minimum of 9 N ensuring that the sensor can withstand handling and installation without damage.

Insulation and Protective Measures

To ensure accurate measurements and longevity, chip type thermal resistance sensors incorporate robust insulation. The insulation resistance is typically 100 MΩ at 20°C, dropping to over 2 MΩ at 500°C. This high insulation resistance prevents current leakage and ensures that the measured resistance truly reflects the temperature of the platinum element.

The sensor may also be encapsulated or coated to protect it from environmental factors such as moisture, chemicals, or mechanical stresses. This protection is crucial for maintaining the sensor's accuracy and reliability over its operational lifetime, which can span many years in some applications.

Operating Principles and Performance Characteristics

The Physics Behind Temperature Sensing

The fundamental principle underlying chip type thermal resistance temperature sensors is the temperature dependence of electrical resistance in metals, particularly platinum. As temperature increases, the vibration of atoms within the metal lattice intensifies, impeding the flow of electrons and thereby increasing electrical resistance. This relationship is highly linear for platinum, making it an ideal material for precise temperature measurements.

The temperature coefficient of resistance (TCR) is a critical parameter that quantifies this relationship. For these sensors, the TCR is typically 3850 ppm/°C, meaning that for every degree Celsius increase in temperature, the resistance increases by 0.385%. This high TCR value ensures excellent sensitivity and resolution in temperature measurements.

Operational Parameters and Considerations

The operating current for chip type thermal resistance sensors is carefully controlled, typically ranging from 0.3 to 1 mA. This low current is chosen to minimize self-heating effects, which could otherwise introduce errors into the temperature measurement. Self-heating occurs when the current passing through the sensor generates heat, potentially raising the sensor's temperature above that of its surroundings.

These sensors boast an impressive operating temperature range, often spanning from -200°C to +850°C. This wide range makes them versatile for applications from cryogenics to high-temperature industrial processes. The accuracy of these sensors can be as high as ±0.01 Ω, translating to temperature measurements with precision better than 0.1°C in many cases.

Dynamic Response and Stability

One of the standout features of chip type thermal resistance sensors is their rapid response time. With response times as low as 0.05 seconds, these sensors can capture fast temperature changes, making them suitable for dynamic environments and control systems that require quick feedback.

Long-term stability is another crucial characteristic. The drift in these sensors is typically ≤ 0.04% over extended periods, ensuring reliable measurements year after year. This stability is complemented by excellent vibration resistance (up to 40g) and impact resistance (up to 100g), making these sensors robust enough for demanding industrial and automotive applications.

Applications and Advantages of Chip Type Thermal Resistance Sensors

Industrial and Process Control Applications

In the realm of industrial process control, chip type thermal resistance temperature sensors have become indispensable. Their high accuracy and stability make them ideal for applications where precise temperature control is critical, such as in chemical reactors, food processing equipment, and semiconductor manufacturing. The sensors' ability to withstand harsh environments, including high temperatures and corrosive atmospheres, ensures reliable operation in a wide range of industrial settings.

These sensors also excel in energy management systems, where they help optimize the efficiency of heating, ventilation, and air conditioning (HVAC) systems. Their quick response time allows for rapid adjustments to changing conditions, resulting in improved energy efficiency and comfort in commercial and residential buildings.

Medical and Laboratory Applications

The medical field has embraced chip type thermal resistance sensors for their precision and reliability. These sensors are used in a variety of medical devices, from patient monitoring systems to diagnostic equipment. Their small size allows for non-invasive temperature measurements, while their accuracy ensures reliable data for critical medical decisions.

In laboratory settings, these sensors play a crucial role in maintaining precise temperatures for experiments and sample storage. They are used in incubators, cryogenic storage systems, and thermal cyclers for PCR (polymerase chain reaction) machines, where even small temperature variations can significantly impact results.

Automotive and Aerospace Applications

The automotive industry relies heavily on chip type thermal resistance sensors for engine management, climate control, and battery monitoring in electric vehicles. These sensors' ability to withstand vibration and extreme temperatures makes them ideal for monitoring critical components such as engine coolant, transmission fluid, and exhaust gas temperatures.

In aerospace applications, these sensors are crucial for monitoring temperatures in aircraft engines, hydraulic systems, and cabin environmental controls. Their high accuracy and stability are essential for ensuring the safety and efficiency of aircraft operations, where reliability is paramount.

Advantages Over Other Temperature Sensing Technologies

Chip type thermal resistance temperature sensors offer several advantages over other temperature sensing technologies. Compared to thermocouples, they provide higher accuracy and stability, especially over long periods. Unlike infrared sensors, they can measure the actual temperature of an object rather than just its surface temperature. Their wide temperature range and linear response make them more versatile than many semiconductor-based temperature sensors.

Additionally, these sensors are relatively immune to electrical noise and can transmit signals over long distances without significant degradation, making them suitable for large-scale industrial installations. Their compatibility with standard resistance measurement techniques also simplifies integration into existing control systems.

Conclusion

Chip type thermal resistance temperature sensors represent a pinnacle of precision temperature measurement technology. Their combination of accuracy, stability, and versatility makes them indispensable in a wide range of applications across industries. As technology continues to advance, these sensors are likely to play an even more critical role in ensuring efficient, safe, and precise temperature control in countless systems and devices.

For those seeking to implement or learn more about chip type thermal resistance temperature sensors, Xi'an Tongzida Technology Co., Ltd. offers expertise and custom solutions. With their advanced manufacturing capabilities and commitment to quality, they are well-positioned to meet the diverse needs of industries relying on precise temperature measurement. For more information or to discuss your specific requirements, please contact them at sales11@xatzd.com.