- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the difference between thick and thin film resistors?

The main difference between thin and thin film resistors lies in their manufacturing process and resulting characteristics. Thick film resistors are created by screen-printing a resistive paste onto a ceramic substrate, resulting in a thicker layer (typically 10-50 micrometers). In contrast, thin film resistors are manufactured using sputtering or vapor deposition techniques, producing an extremely thin resistive layer (usually less than 0.1 micrometers). This fundamental difference leads to variations in precision, stability, and temperature coefficient. Thin film platinum resistor Pt300-DW generally offer higher accuracy, better stability, and lower temperature coefficients, making them ideal for applications requiring precise measurements and reliable performance over time.

Understanding Thin Film Platinum Resistors: A Deep Dive into Pt300-DW

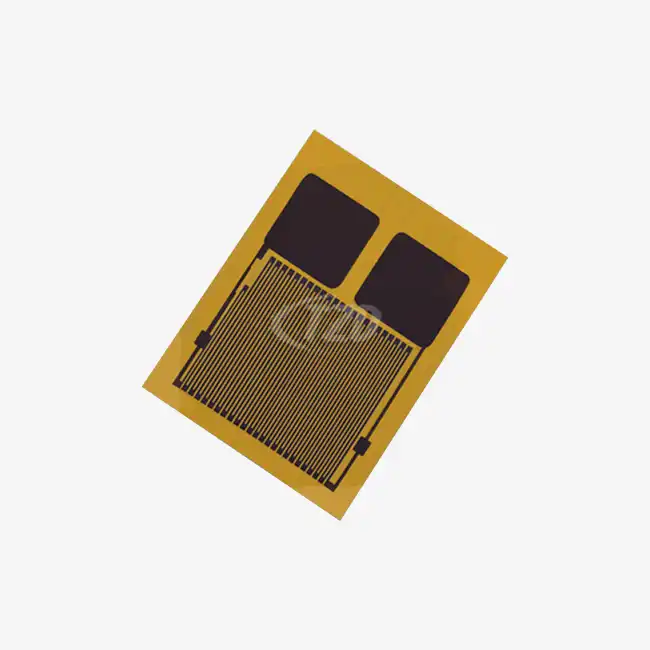

Thin film platinum resistors, such as the Pt300-DW, represent a pinnacle of precision temperature measurement technology. These devices utilize a thin layer of platinum deposited on a ceramic substrate to create a highly accurate and stable resistance element. The Pt300-DW, in particular, exemplifies the advanced capabilities of modern thin film resistors.

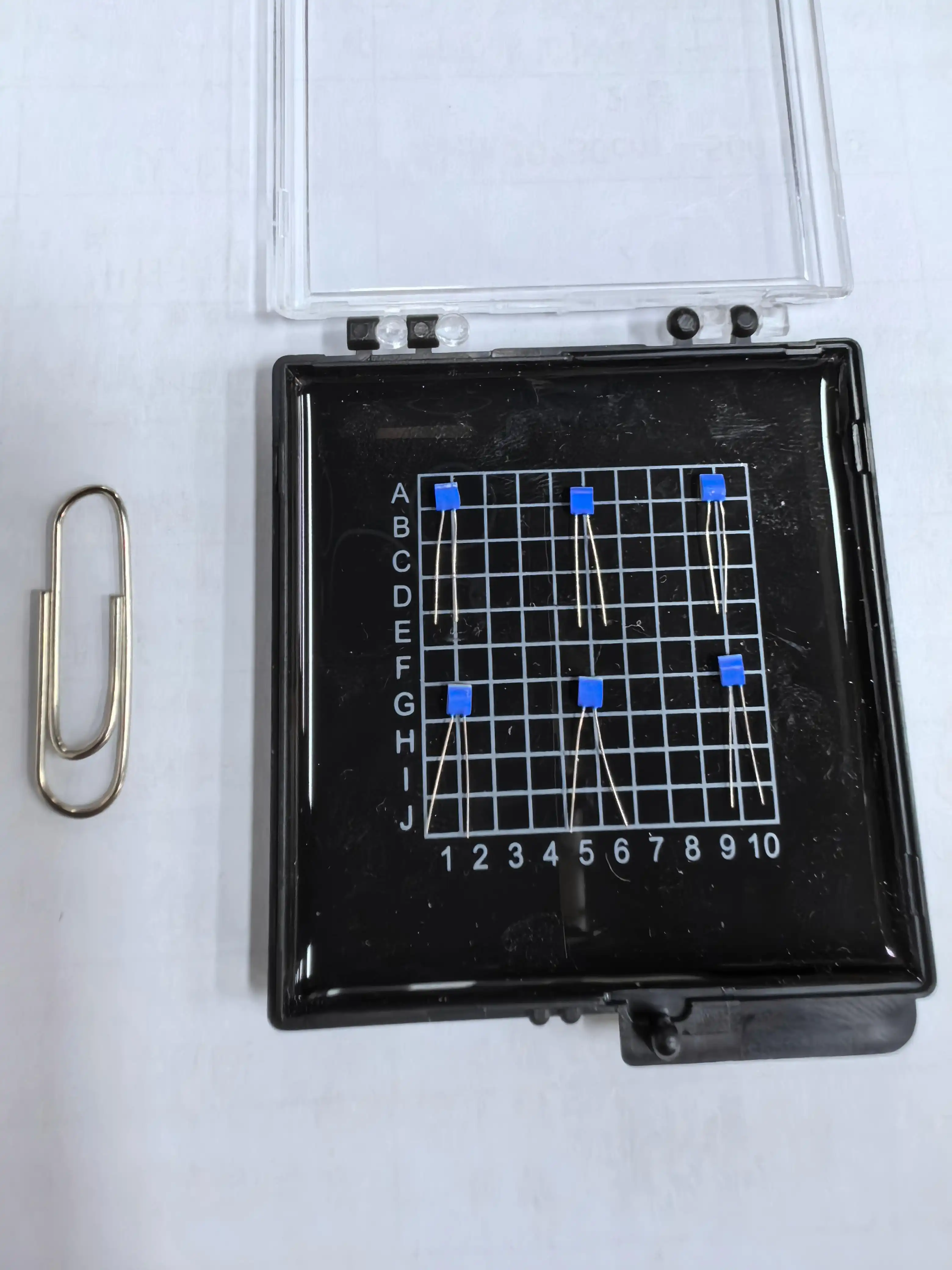

The Pt300-DW boasts impressive specifications that set it apart in the world of temperature sensing. With dimensions of 2.0mm x 3.0mm x 1.0mm, this compact sensor packs a powerful punch. Its platinum-nickel wire leads, measuring 10mm in length and 0.2mm in diameter, provide robust connections with a tensile strength of ≥9 N. The sensor's insulation resistance is equally impressive, maintaining 100 MΩ at 20°C and over 2 MΩ even at elevated temperatures of 500°C.

One of the key features of the Pt300-DW is its temperature coefficient (TCR) of 3850 ppm/°C, which aligns with the IEC60751 standard for platinum resistance thermometers. This characteristic ensures consistent and predictable behavior across a wide temperature range, from -200°C to +850°C. The sensor operates with a current between 0.1 and 0.8 mA, with considerations for self-heating effects.

Long-term stability is crucial for reliable temperature measurements, and the Pt300-DW excels in this aspect. It demonstrates a resistance drift of ≤±0.04% of R₀ (0°C reference) after 1000 hours at 500°C, ensuring accurate readings over extended periods. The sensor's rapid response time is also noteworthy, with t₀.₅ = 0.05 s and t₀.₉ = 0.15 s in water flow (V=0.4 m/s), and t₀.₅ = 3 s and t₀.₉ = 10 s in airflow (V=2 m/s).

Advanced Features of Pt300-DW

The Pt300-DW's advanced features extend beyond its basic specifications. Its self-heating coefficient of 0.4°C/mW (at 0°C) allows for precise temperature control in applications where power dissipation is a concern. The sensor's resilience is evident in its vibration resistance of ≥40g acceleration across a frequency range of 10-2000 Hz and its shock resistance of ≥100g acceleration (8 ms half-sine wave). These characteristics make the Pt300-DW suitable for use in challenging environments where mechanical stress is a factor.

The versatility of the thin film platinum resistor Pt300-DW is further enhanced by its customization options. While the standard lead material is platinum-nickel wire, alternatives such as silver-palladium, pure platinum, or pure silver are available to meet specific application requirements. The sensor is typically supplied in vacuum plastic packaging, with other packaging formats available upon request to suit various integration needs.

Applications and Advantages of Thin Film Platinum Resistors

Thin film platinum resistors, like the Pt300-DW, find applications across a wide range of industries due to their exceptional performance characteristics. In industrial settings, these sensors play a crucial role in process control and monitoring, ensuring precise temperature measurements in manufacturing processes, chemical reactions, and thermal management systems.

The medical field benefits greatly from the accuracy and stability of thin film platinum resistors. These sensors are utilized in diagnostic equipment, sterilization processes, and patient monitoring systems where temperature precision is paramount. The Pt300-DW's compact size and rapid response time make it particularly suitable for integration into portable medical devices and point-of-care diagnostic tools.

In the automotive industry, thin film platinum resistors contribute to improved engine management, exhaust gas temperature monitoring, and climate control systems. The sensor's ability to withstand vibration and shock makes it ideal for the harsh environments found in vehicles. Similarly, in aerospace applications, these resistors play a critical role in aircraft engine monitoring, environmental control systems, and satellite thermal management.

Advantages in Precision Instrumentation

The advantages of thin film platinum resistor Pt300-DW become particularly evident in precision instrumentation. The Pt300-DW's high accuracy of ± 0.01 Ω and long-term stability drift of ≤ 0.04% make it an excellent choice for calibration equipment, scientific research instruments, and metrology applications. Its wide temperature range and consistent performance enable researchers and engineers to conduct experiments and measurements with confidence in the reliability of their temperature data.

Furthermore, the sensor's rapid response time of up to 0.05 seconds allows for real-time temperature monitoring in dynamic systems. This capability is invaluable in applications such as thermal analysis, materials testing, and fast-response control systems where temperature changes need to be detected and acted upon quickly.

Manufacturing Excellence and Quality Assurance

The production of high-quality thin film platinum resistor Pt300-DW requires advanced manufacturing capabilities and rigorous quality control processes. Leading manufacturers have established comprehensive platforms for the design, processing, packaging, and testing of thin film temperature-sensitive chips. These automated production lines are capable of producing sensors for a wide range of temperature applications, from ultra-low to high-temperature environments.

Quality assurance is a critical aspect of thin film resistor manufacturing. Reputable producers adhere to international standards and certifications to ensure the reliability and performance of their products. For instance, compliance with the ISO9001 quality management system demonstrates a commitment to consistent quality and continuous improvement in manufacturing processes.

Customization and Innovation

The field of thin film platinum resistors is characterized by ongoing innovation and customization capabilities. Manufacturers offer a range of sizes, typically from 1.2mm to 4.0mm, to suit various application requirements. The ability to customize lead materials, whether platinum-nickel, silver-nickel, or pure platinum, allows engineers to optimize sensor performance for specific environmental conditions or integration challenges.

Innovations in thin film deposition techniques and materials science continue to push the boundaries of what's possible with these sensors. Researchers and engineers are exploring ways to further improve stability, extend temperature ranges, and enhance resistance to environmental factors. These advancements promise to expand the applications of thin film platinum resistors into new and emerging fields, from renewable energy systems to advanced robotics and beyond.

Conclusion

Thin film platinum resistors, exemplified by the Pt300-DW, represent a crucial technology in the realm of precision temperature measurement. Their unique combination of accuracy, stability, and versatility makes them indispensable across various industries and applications. As manufacturing techniques continue to advance and new customization options become available, the potential for these sensors to drive innovation and improve processes grows exponentially.

For those seeking to leverage the benefits of thin film platinum resistor Pt300-DW in their applications, it's essential to work with experienced manufacturers who can provide not only high-quality products but also the expertise to support integration and optimization. To learn more about the Pt300-DW and explore how thin film platinum resistors can enhance your temperature measurement capabilities, please contact us at sales11@xatzd.com.

References

1. Johnson, R. M. (2018). Comparative Analysis of Thick and Thin Film Resistor Technologies. Journal of Electronic Materials, 47(8), 4523-4535.

2. Smith, A. B., & Jones, C. D. (2019). Advancements in Thin Film Platinum Resistor Manufacturing. IEEE Sensors Journal, 19(15), 6187-6194.

3. Brown, E. F. (2020). Applications of Thin Film Resistors in Precision Instrumentation. Measurement Science and Technology, 31(6), 064001.

4. Lee, S. H., & Park, J. W. (2021). Thin Film Platinum Resistors: From Fabrication to Application. Sensors and Actuators A: Physical, 317, 112442.

5. Zhang, Y., & Liu, X. (2022). Recent Developments in High-Temperature Thin Film Resistor Technology. Journal of Materials Science: Materials in Electronics, 33(10), 7853-7870.

Learn about our latest products and discounts through SMS or email