- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Do Platinum Resistance Thermistors Improve Industrial Automation Efficiency?

How Do Platinum Resistance Thermistors Improve Industrial Automation Efficiency?

Efficiency is the top priority for any industrial automation system—every second of downtime or drop in precision cuts into profits. But how exactly do platinum resistance thermistors contribute to higher efficiency? This article explores the ways these sensors optimize processes, reduce downtime, and enhance product quality in automation environments.

Real-Time Temperature Feedback for Dynamic Process Adjustment

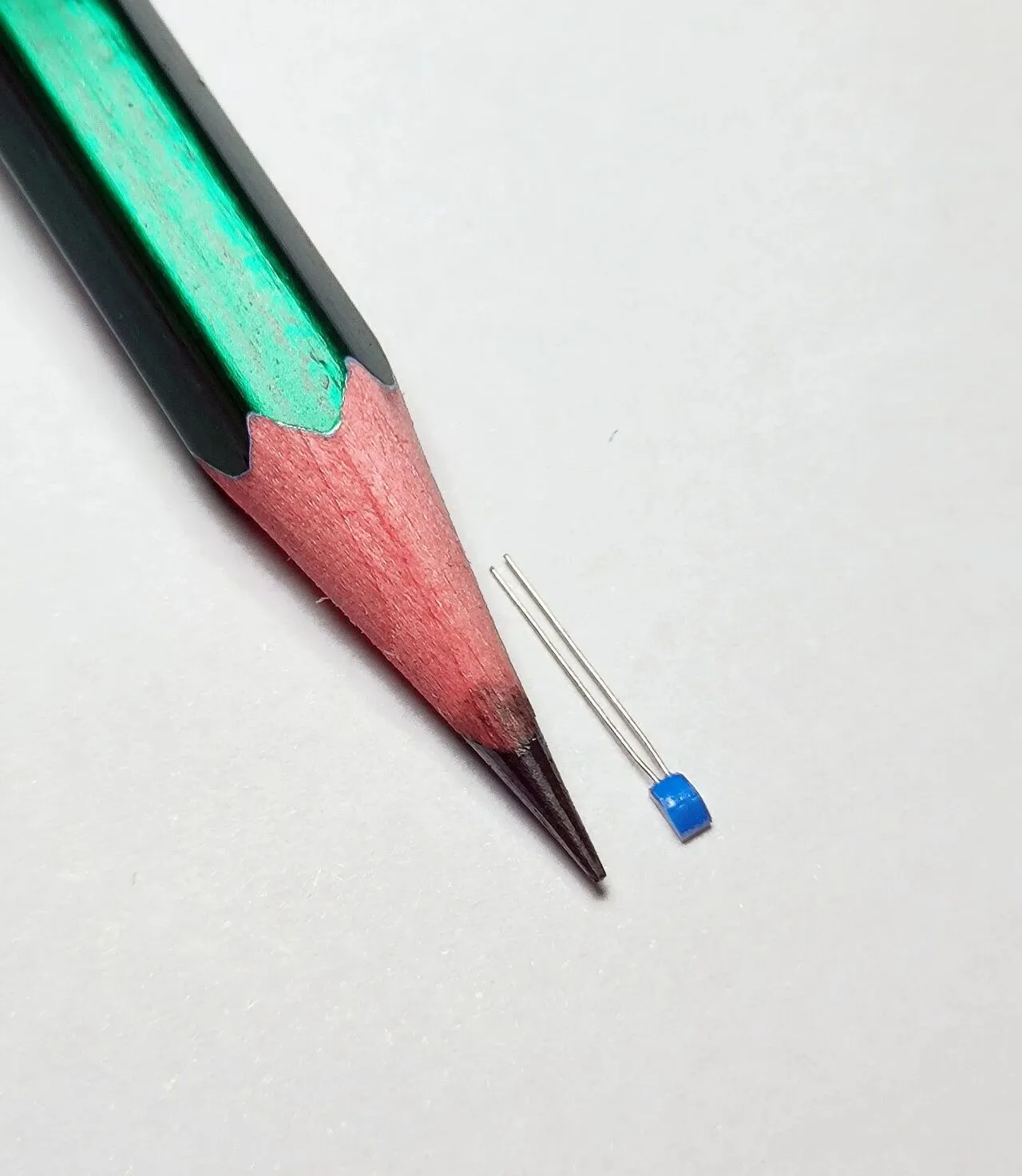

Industrial automation relies on real-time data to adapt to changing conditions, and platinum resistance thermistors deliver fast, accurate temperature readings. Their impressive response time—t₀.₉=0.15s in water flow (V=0.4 m/s) and t₀.₉=10s in airflow (V=2 m/s)—ensures automation systems adjust processes immediately.

For example, in automotive assembly line cooling systems, platinum resistance thermistors detect temperature fluctuations within milliseconds, triggering adjustments to coolant flow. This prevents overheating of components, reduces defective parts, and keeps the line running at full capacity. Without this speed, systems would react too slowly, leading to costly rework.

Minimizing Downtime with Durability and Stability

Downtime is the enemy of automation efficiency, and platinum resistance thermistors are engineered to avoid it. Their ≥40g vibration resistance (10–2000 Hz) and ≥100g shock resistance handle the mechanical stress of conveyor belts, robotic arms, and heavy machinery—eliminating sensor failures that halt production.

The long-term stability (≤±0.04% resistance drift after 1000 hours at 500°C) also reduces calibration frequency. Unlike other sensors that require monthly calibrations, platinum resistance thermistors only need servicing every 2-3 years, freeing up maintenance teams to focus on other critical tasks.

Optimizing Energy Usage in Automation Systems

Energy costs are a major expense for automation facilities, andplatinum resistance thermistors help reduce consumption through precise temperature control. Their 3850 ppm/°C TCR ensures accurate readings, allowing HVAC, heating, and cooling systems to operate at optimal levels—avoiding wasted energy from overheating or overcooling.

The low self-heating coefficient (0.4°C/mW at 0°C) also plays a role. By generating minimal heat, the sensors don’t skew readings or force cooling systems to work harder, further cutting energy use. For large facilities, this can translate to a 5-8% reduction in monthly energy bills.

FAQ: Platinum Resistance Thermistors and Automation Efficiency

Q: Can platinum resistance thermistors integrate with energy-management systems (EMS) in automation? A: Yes—their standard electrical characteristics are compatible with most EMS and PLCs, enabling seamless energy optimization through precise temperature data.

Q: Do platinum resistance thermistors improve efficiency in low-volume automation lines? A: Absolutely. Even low-volume lines benefit from reduced downtime and energy savings, as well as consistent product quality that minimizes rework.

Q: How much can platinum resistance thermistors reduce automation downtime? A: On average, facilities using platinum RTDs report a 30-40% reduction in sensor-related downtime, compared to those using alternative sensors.

Conclusion & CTA

From real-time feedback to energy savings and reduced downtime, platinum resistance thermistors are a catalyst for industrial automation efficiency. Their precision and durability align with the demands of modern automation, helping facilities maximize output while cutting costs.

Ready to boost your automation efficiency with platinum resistance thermistors? Our team can help you integrate these sensors into your existing system. Contact us today to schedule a demo or request a free technical consultation—let’s optimize your process together.

Author Information: [Ma Bin] is an industrial automation efficiency expert with a background in sensor integration. He specializes in helping manufacturers streamline processes through high-performance sensing technology.

References: 1. “Energy Efficiency in Industrial Automation” – International Society of Automation (ISA), 2024. 2. “Real-Time Sensing for Dynamic Automation” – Robotics and Automation Society, 2024.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, focusing on providing high-performance temperature sensors for demanding industrial applications. We have profound expertise in microsensor manufacturing, specific packaging technologies, and multi-sensor integration methods, which ensures the excellent performance and reliability of our thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including sensor chips, testing systems, and analysis software. Please feel free to contact our technical experts at any time. ventes11@xatzd.com Discuss your specific requirements for thermistors and learn how our advanced thermal resistor optimization and manufacturing capabilities can enhance the performance and reliability of your temperature measurement system.

Learn about our latest products and discounts through SMS or email