- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Are Platinum Resistance Thermistors Worth It for Industrial Automation? Cost-Benefit Analysis

Are Platinum Resistance Thermistors Worth It for Industrial Automation? Cost-Benefit Analysis

Investing in temperature sensors for industrial automation requires balancing cost and performance. Are platinum resistance thermistors a worthwhile investment, or should you opt for cheaper alternatives like NTC thermistors or basic thermocouples? This article breaks down the cost-benefit ratio of platinum resistance thermistors, showing why they deliver long-term value for automation facilities despite a higher upfront cost.

Upfront Cost vs. Long-Term Savings of Platinum Resistance Thermistors

It’s true—platinum resistance thermistors have a higher initial price tag compared to NTC thermistors or low-grade thermocouples. However, their durability and stability translate to significant long-term savings. For example, a standard NTC thermistor may cost 30% less upfront but requires replacement every 1-2 years due to poor stability, while platinum resistance thermistors last 5-10 years in continuous industrial use.

The ≤±0.04% resistance drift after 1000 hours at 500°C means fewer calibrations (typically once every 2-3 years vs. quarterly for alternatives), reducing labor costs and downtime. For an automation line running 24/7, even 1 hour of downtime can cost thousands—making the stability of platinum resistance thermistors a cost-effective choice.

Cost Drivers of Platinum Resistance Thermistors

1. Material and Manufacturing Quality

Platinum’s inherent stability and corrosion resistance are key cost drivers, but they’re also what make the sensors reliable. The use of high-purity platinum (99.99%+) and precision manufacturing processes (to meet 3850 ppm/°C TCR) contribute to upfront costs, but they eliminate the risk of inaccurate readings that lead to defective products.

2. Customization Options

Custom lead materials (silver-palladium, pure platinum) or packaging add modest costs but tailor the sensor to harsh automation environments. For example, silver-palladium leads cost 15% more than standard platinum-nickel but resist corrosion in chemical processing automation, avoiding costly sensor failures.

When Cheaper Alternatives Fall Short in Automation

Cheaper sensors often fail to meet the demands of industrial automation. Thermocouples, for instance, lack precision in moderate temperature ranges (20°C-500°C)—the sweet spot for most automation processes—leading to inconsistent product quality. NTC thermistors suffer from self-heating issues (up to 2°C/mW vs. 0.4°C/mW for platinum RTDs), causing inaccurate readings in confined spaces like robot control units.

In high-vibration automation environments, cheaper sensors break easily—their vibration resistance (typically ≤20g) can’t match the ≥40g acceleration tolerance of platinum resistance thermistors. This means frequent replacements and unplanned downtime, erasing any upfront cost savings.

FAQ: Cost-Benefit of Platinum Resistance Thermistors

Q: For small automation facilities, are platinum resistance thermistors still worth it? A: Yes—even small facilities benefit from reduced downtime and replacements. We offer cost-effective standard models that retain core specs (3850 ppm/°C TCR, ≥40g vibration resistance) for budget-conscious buyers.

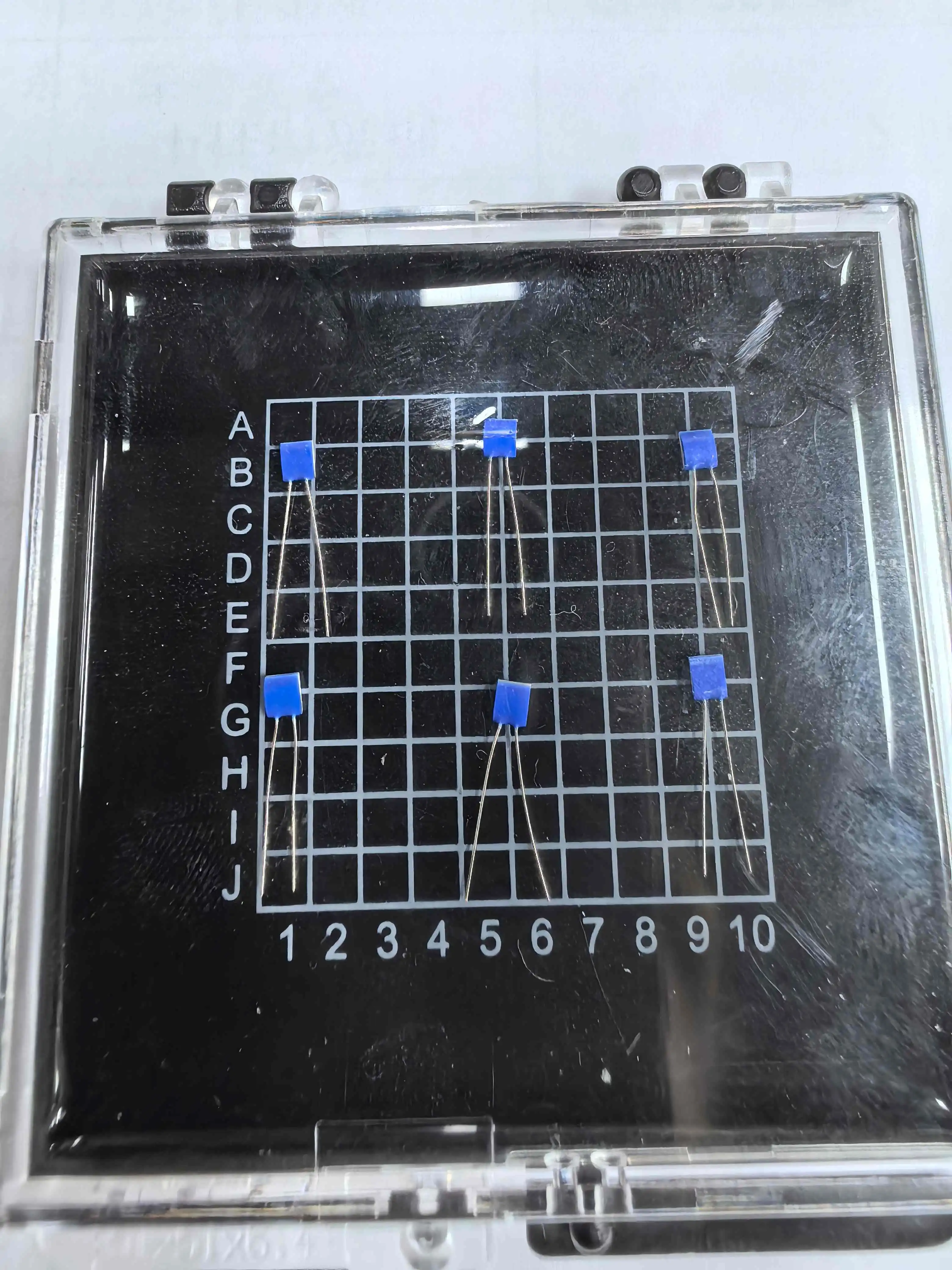

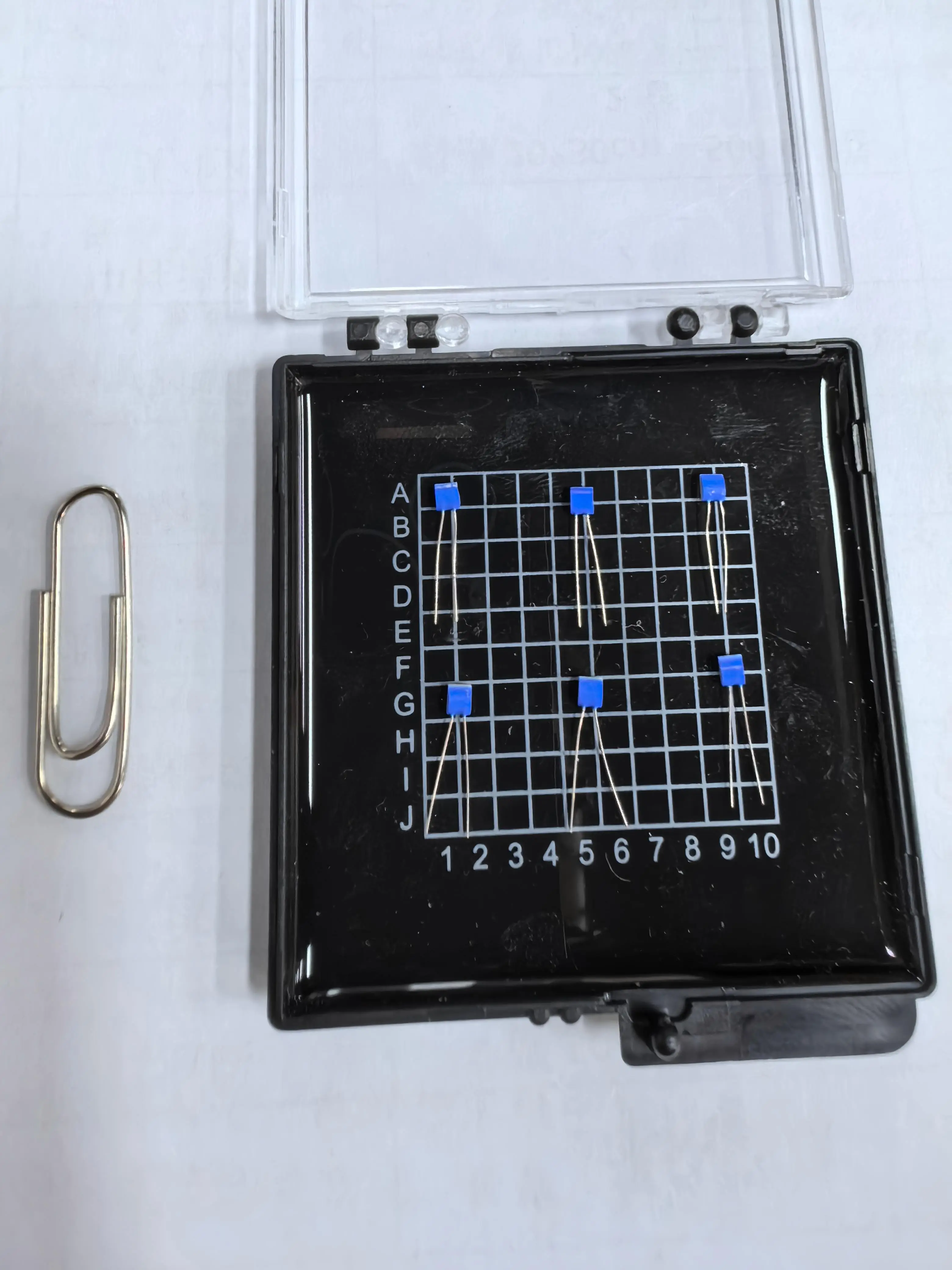

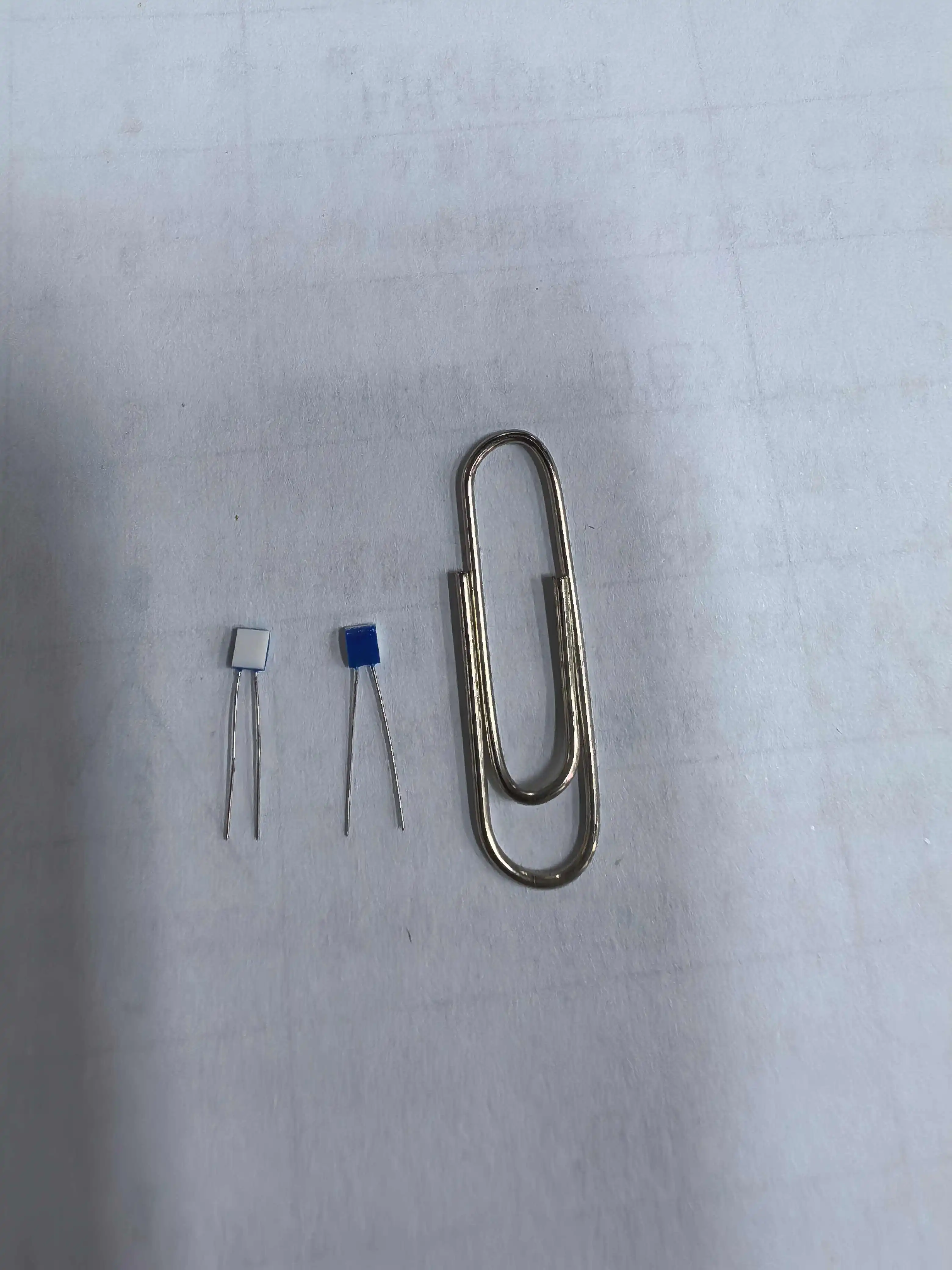

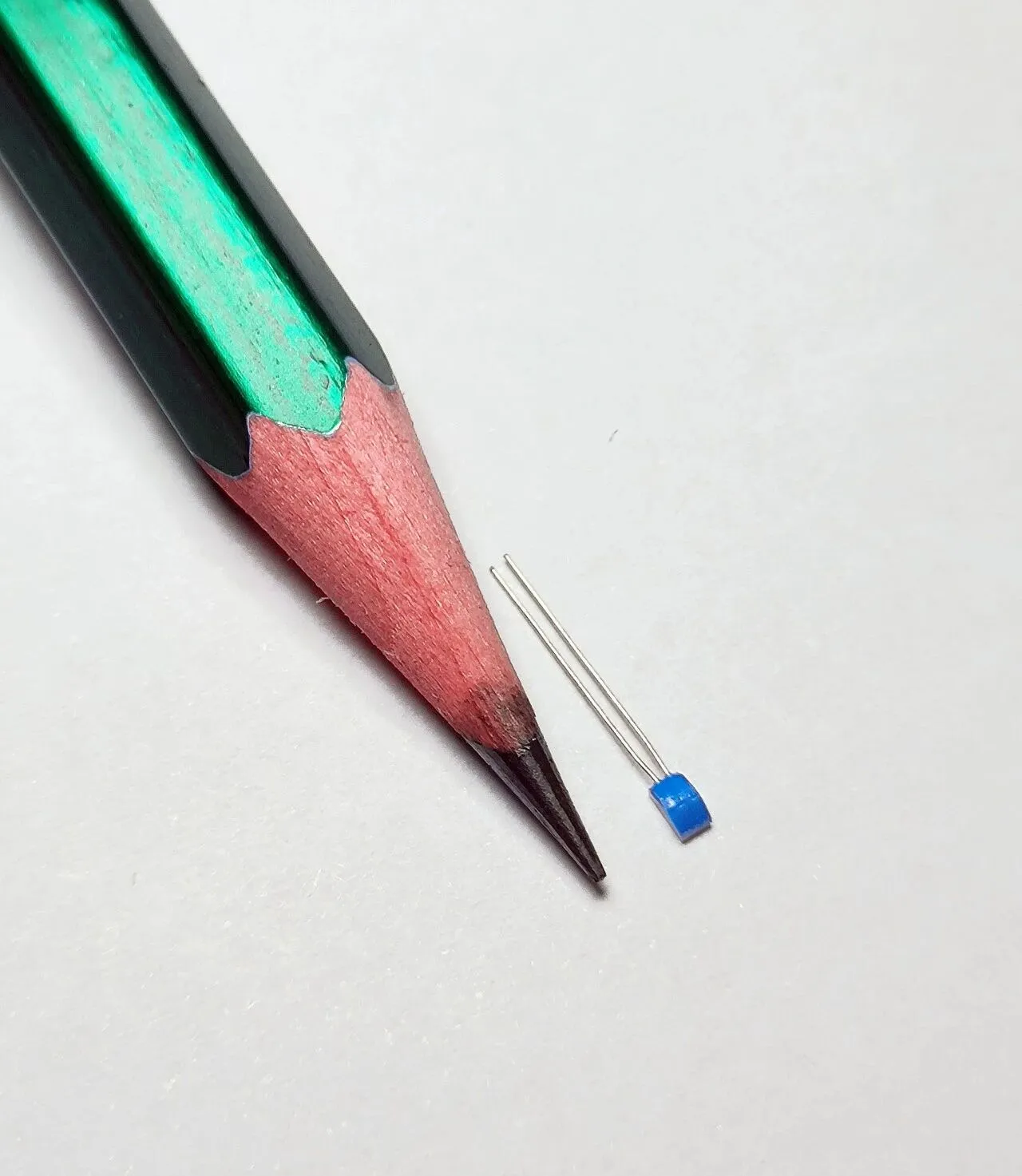

Q: Can I reduce costs by choosing standard vs. custom platinum resistance thermistors? A: Absolutely. Our standard models (2.0mm×2.3mm×1.0mm, platinum-nickel leads) offer the same stability and durability as custom versions, with lower costs for bulk orders (1000+ units).

Q: How quickly do platinum resistance thermistors pay for themselves? A: Typically within 12-18 months, thanks to reduced replacements, calibrations, and downtime. For high-volume automation lines, the payback period can be as short as 6 months.

Conclusion & CTA

While platinum resistance thermistors have a higher upfront cost, their long-term savings, durability, and precision make them a worthwhile investment for industrial automation. Cheaper alternatives may seem appealing initially, but they lead to increased downtime, calibration costs, and defective products—eroding profits over time.

If you’re weighing sensor options for your automation system, contact our team for a personalized cost-benefit analysis. We’ll help you choose between standard and custom platinum resistance thermistors to fit your budget and performance needs. Request a free quote today to see how much you can save long-term.

Author Information:

[Xu Fei] is a cost-optimization consultant for industrial automation, with expertise in sensor technology. He helps manufacturers balance performance and budget to maximize operational efficiency.

References:

1. “Cost-Benefit Analysis of Industrial Temperature Sensors” – Industrial Automation Magazine, 2024.

2. IEC 60751:2022. Industrial platinum resistance thermometers and platinum temperature sensors.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, focusing on providing high-performance temperature sensors for demanding industrial applications. We have profound expertise in microsensor manufacturing, specific packaging technologies, and multi-sensor integration methods, which ensures the excellent performance and reliability of our thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including sensor chips, testing systems, and analysis software. Please feel free to contact our technical experts at any time. ventes11@xatzd.com Discuss your specific requirements for thermistors and learn how our advanced thermal resistor optimization and manufacturing capabilities can enhance the performance and reliability of your temperature measurement system.

Learn about our latest products and discounts through SMS or email