- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Platinum Resistance Thermistors vs. Thermocouples: Which Is Better for Industrial Automation?

Platinum Resistance Thermistors vs. Thermocouples: Which Is Better for Industrial Automation?

Thermocouples and platinum resistance thermistors are the two most common temperature sensors in industrial automation. Both have their strengths, but choosing the wrong one can lead to inefficiency, poor quality, and increased costs. This comparison covers accuracy, stability, cost, and compatibility to help you choose the right sensor for your automation needs.

Accuracy and Temperature Range: A Critical Distinction

The biggest difference between the two sensors lies in accuracy and operating range. Thermocouples excel in extreme high temperatures (up to 1700°C) but lack precision in the moderate range (20°C-500°C)—the most common range for industrial automation processes like assembly line heating, HVAC, and robotic temperature control.

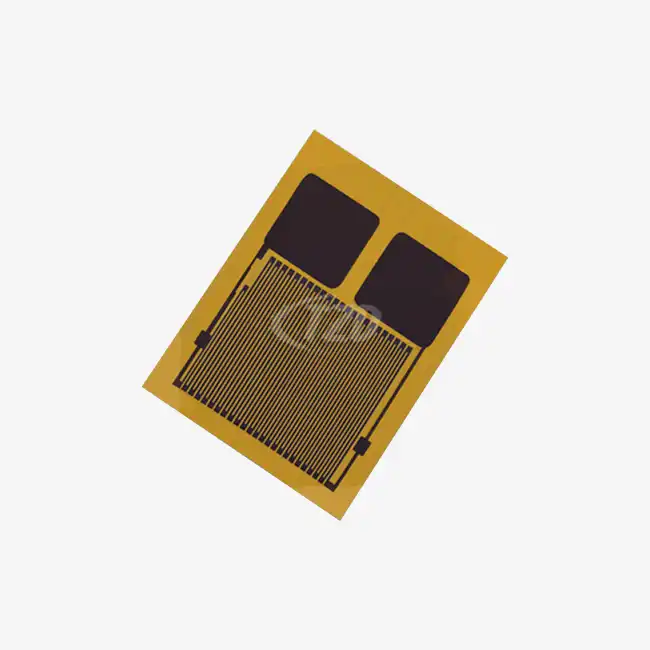

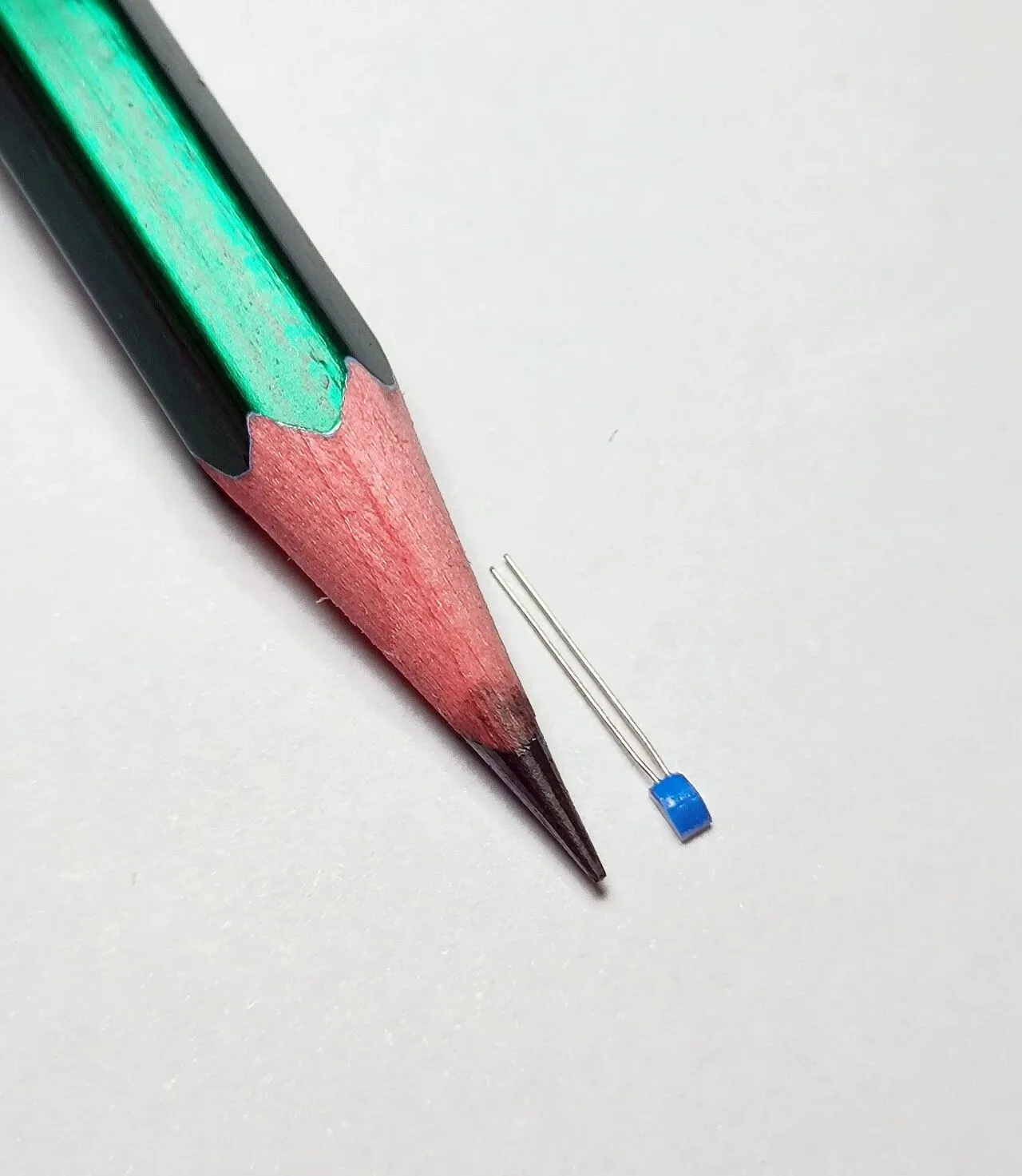

Platinum resistance thermistors offer superior accuracy (±0.1°C vs. ±1°C for thermocouples) in this moderate range, thanks to their 3850 ppm/°C TCR. For applications like semiconductor manufacturing or food processing automation, this precision ensures consistent product quality. Thermocouples, by contrast, may lead to variations that require rework or scrapping.

Stability and Longevity: Which Lasts Longer in Automation?

Industrial automation demands 24/7 operation, so sensor stability is non-negotiable. Platinum resistance thermistors offer exceptional long-term stability: ≤±0.04% resistance drift after 1000 hours at 500°C, meaning they maintain accuracy for years. Thermocouples, however, suffer from drift (up to ±5% after 1000 hours) due to alloy degradation, requiring frequent replacement (every 1-2 years).

The mechanical durability of platinum resistance thermistors also gives them an edge. Their ≥40g vibration resistance and ≥100g shock resistance outperform thermocouples (typically ≤30g vibration resistance), making them more durable in high-stress automation environments.

Cost, Complexity, and Integration

1. Cost Considerations

Thermocouples have a lower upfront cost (30-50% less than platinum RTDs), but their short lifespan and frequent calibrations make them more expensive long-term. Platinum resistance thermistors have a higher initial cost but pay for themselves within 12-18 months through reduced downtime and maintenance.

2. Integration and Complexity

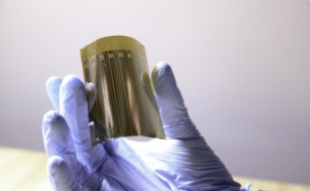

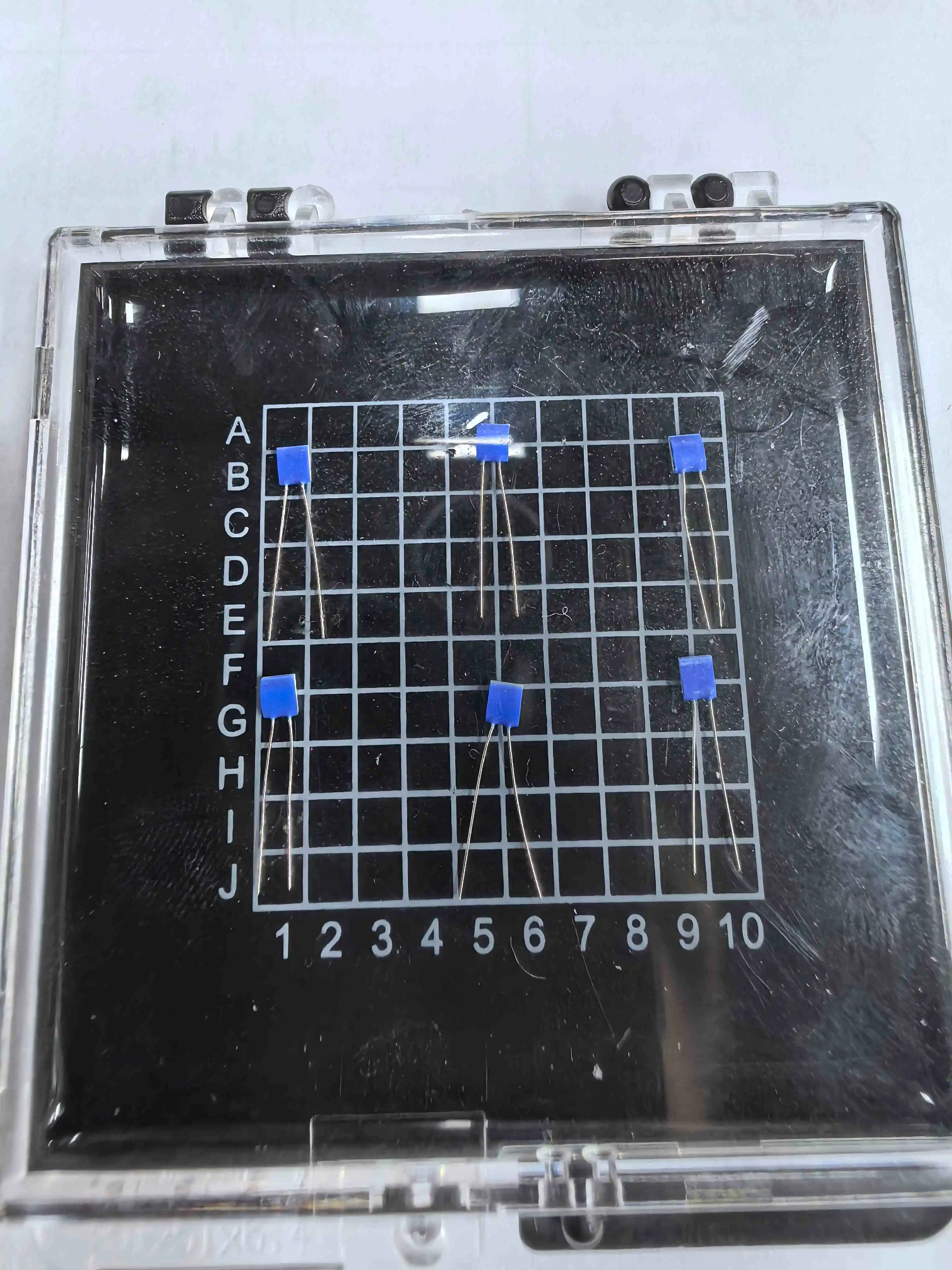

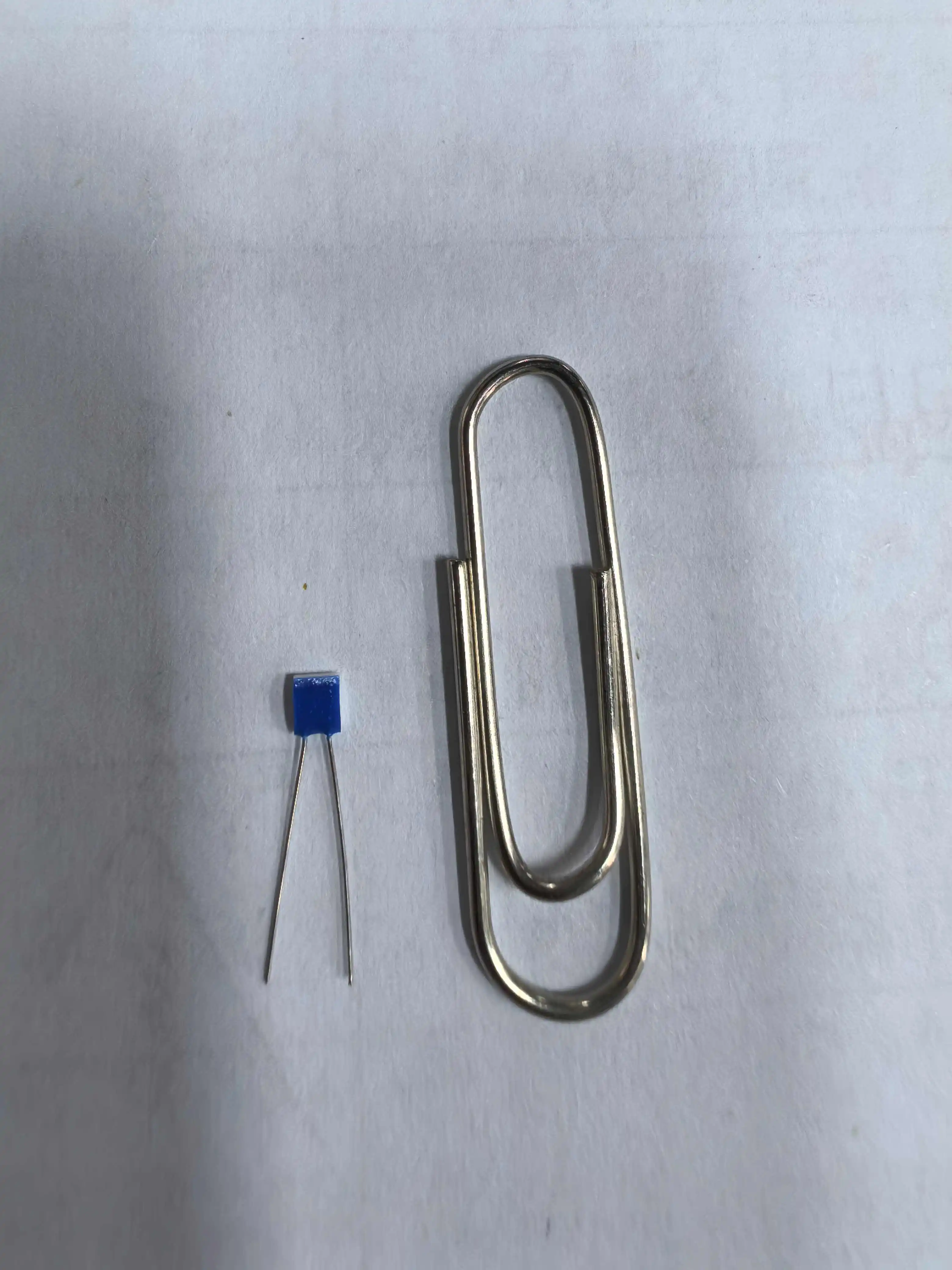

Thermocouples require a reference junction to maintain accuracy, adding complexity to automation system design. Platinum resistance thermistors have no such requirement—they integrate seamlessly with PLCs and automation controllers via standard leads (10mm length, 0.2mm diameter), simplifying installation and reducing setup costs.

FAQ: Choosing Between Platinum RTDs and Thermocouples

Q: For high-heat automation processes (above 500°C), which sensor is better? A: Thermocouples are better for temperatures above 500°C. For processes between -50°C and 500°C (most automation), platinum RTDs offer superior accuracy.

Q: Are platinum resistance thermistors harder to install than thermocouples? A: No—they’re easier. Platinum RTDs don’t need a reference junction, and their standard leads fit most automation setups without modifications.

Q: For budget-constrained automation projects, should I choose thermocouples? A: Consider short-term vs. long-term costs. If the project is temporary (≤2 years), thermocouples may work. For permanent automation, platinum RTDs are more cost-effective.

Conclusion & CTA

For most industrial automation applications (moderate temperatures, 24/7 operation, precision requirements), platinum resistance thermistors outperform thermocouples. They offer better accuracy, stability, and long-term value, while simplifying integration into existing systems. Thermocouples are only preferable for extreme high-temperature processes.

Not sure which sensor fits your automation process? Our team can evaluate your temperature range, environment, and budget to make a personalized recommendation. Contact us today to request a free sensor comparison guide or sample testing.

Author Information:

[Han Liang] is a sensor technology specialist with expertise in industrial automation. He helps manufacturers select the right temperature sensors to optimize performance and cost.

References:

1. IEC 60751:2022. Industrial platinum resistance thermometers and platinum temperature sensors.

2. ANSI/ASTM E230-22. Standard Specification for Thermocouples for Temperature Measurement.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, focusing on providing high-performance temperature sensors for demanding industrial applications. We have profound expertise in microsensor manufacturing, specific packaging technologies, and multi-sensor integration methods, which ensures the excellent performance and reliability of our thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including sensor chips, testing systems, and analysis software. Please feel free to contact our technical experts at any time. ventes11@xatzd.com Discuss your specific requirements for thermistors and learn how our advanced thermal resistor optimization and manufacturing capabilities can enhance the performance and reliability of your temperature measurement system.

Learn about our latest products and discounts through SMS or email