- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How do thin film resistors work?

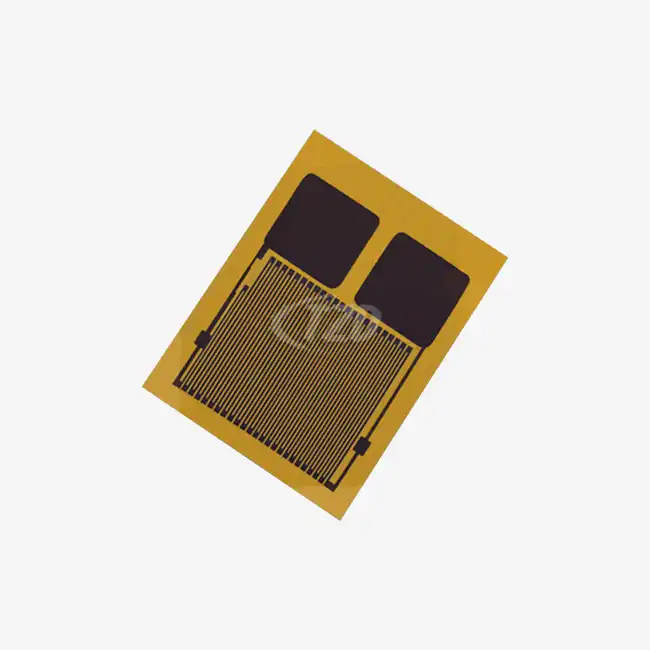

Thin film resistors, particularly the thin film platinum resistor Pt20-DW, operate on the principle of electrical resistance in a precisely deposited metallic film. These advanced components utilize a thin layer of resistive material, often platinum, applied to a ceramic substrate through vapor deposition or sputtering techniques. As temperature fluctuates, the resistance of this film changes proportionally, allowing for accurate temperature measurements. The Pt20-DW's unique construction, featuring a platinum film mere nanometers thick, ensures rapid response to temperature variations and exceptional stability over time, making it an indispensable tool in various high-precision applications.

The Innovative Design of Thin Film Platinum Resistors

The Thin Film Platinum Resistor Pt20-DW represents a pinnacle in resistor technology, combining cutting-edge materials with precision engineering. At its core, this device leverages the temperature-dependent resistivity of platinum to achieve unparalleled accuracy in temperature sensing. The resistor's foundation is a carefully selected ceramic substrate, chosen for its thermal stability and electrical insulation properties.

Platinum Deposition Process

The heart of the Pt20-DW lies in its platinum film, deposited with exacting precision. This process involves the vaporization of pure platinum in a vacuum chamber, allowing the metal to condense on the ceramic substrate in a uniform, ultra-thin layer. The thickness of this film is controlled to nanometer precision, typically ranging from 10 to 100 nanometers. This meticulous deposition ensures consistency in electrical properties across the entire surface of the resistor.

Trimming and Calibration

Following deposition, the resistor undergoes a series of trimming and calibration steps. Laser trimming adjusts the resistance value to meet exact specifications, while thermal cycling and aging processes ensure long-term stability. These steps are crucial in achieving the Pt20-DW's remarkable accuracy of ±0.01 Ω and its ability to maintain performance over extended periods.

Lead Attachment and Encapsulation

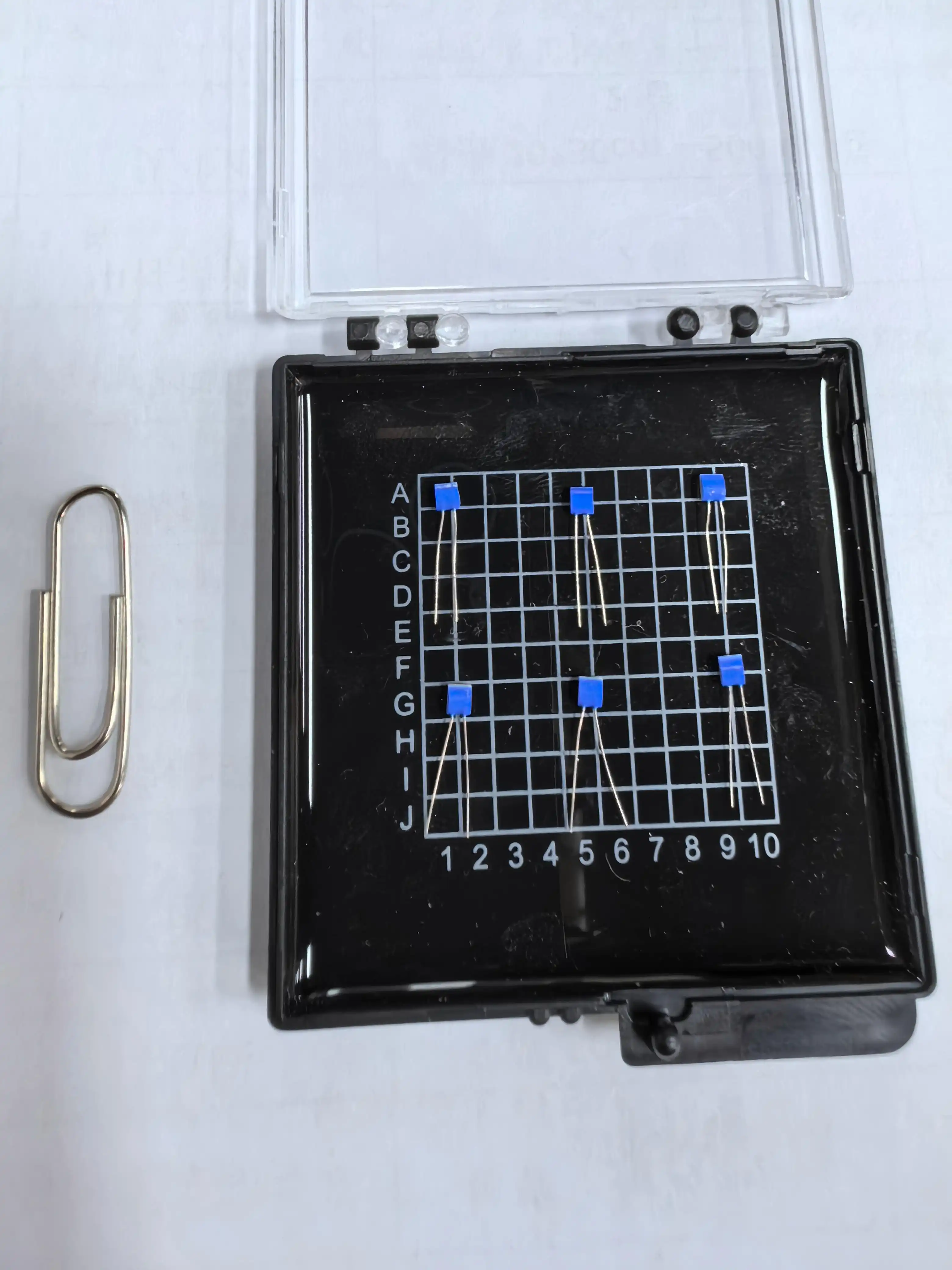

The thin film platinum resistor Pt20-DW's functionality is further enhanced by its carefully designed lead system. Platinum-nickel wires, measuring 10 mm in length and 0.2 mm in diameter, are attached to the resistive element. These leads boast a tensile strength of ≥9 N, ensuring durability in demanding applications. The entire assembly is then encapsulated in a protective coating, often utilizing vacuum plastic packaging to shield the sensitive components from environmental factors.

Unparalleled Performance: Characteristics of the Pt20-DW

The Thin Film Platinum Resistor Pt20-DW stands out for its exceptional performance characteristics, making it a preferred choice in high-precision temperature measurement applications. Its design and construction contribute to a set of impressive specifications that set new standards in the field of temperature sensing.

Temperature Coefficient and Range

One of the most critical parameters of the Pt20-DW is its temperature coefficient of resistance (TCR), which stands at 3850 ppm/°C. This high TCR value ensures excellent sensitivity to temperature changes, allowing for precise measurements across a wide range. The Pt20-DW can operate effectively from -200°C to +850°C, covering an expansive temperature spectrum suitable for diverse industrial and scientific applications.

Response Time and Self-Heating

The thin film platinum resistor Pt20-DW excels in rapid response to temperature fluctuations. In water flow conditions (V=0.4 m/s), it achieves a t₀.₅ of 0.05 seconds and a t₀.₉ of 0.15 seconds. Even in airflow (V=2 m/s), the response times remain impressive at t₀.₅ = 3 seconds and t₀.₉ = 10 seconds. This quick response is complemented by a low self-heating coefficient of 0.4°C/mW at 0°C, minimizing measurement errors due to the sensor's own heat generation.

Stability and Resistance to Environmental Factors

Long-term stability is a hallmark of the Pt20-DW, with a resistance drift of ≤±0.04% of R₀ (0°C reference) after 1000 hours at 500°C. This exceptional stability ensures reliable measurements over extended periods, even in high-temperature environments. The resistor also demonstrates remarkable resilience to mechanical stresses, withstanding vibrations of ≥40g acceleration in the 10-2000 Hz frequency range and shock resistance of ≥100g acceleration under an 8 ms half-sine wave.

Applications and Advantages in High-Demand Industries

The Thin Film Platinum Resistor Pt20-DW's superior characteristics make it an invaluable component in various high-demand industries. Its versatility and reliability have led to its adoption in applications ranging from industrial process control to cutting-edge aerospace technologies.

Industrial Process Control

In industrial settings, the Pt20-DW's wide temperature range and high accuracy are crucial for maintaining precise control over manufacturing processes. Its rapid response time allows for real-time temperature monitoring in chemical reactions, metallurgy, and food processing. The resistor's stability and resistance to vibration make it ideal for use in heavy machinery and production lines where consistent performance is essential.

Medical and Laboratory Applications

The medical field benefits from the thin film platinum resistor Pt20-DW's exceptional accuracy and quick response. It finds use in diagnostic equipment, sterilization processes, and laboratory incubators where temperature control is critical. The resistor's small size (2.0mm x 2.3mm x 1.0mm) allows for integration into compact medical devices without compromising performance.

Automotive and Aerospace Industries

In the automotive sector, the Pt20-DW's resilience to vibration and shock makes it suitable for engine management systems and exhaust gas temperature monitoring. The aerospace industry leverages its wide temperature range and stability for applications in aircraft engines, environmental control systems, and space exploration equipment. The resistor's ability to maintain accuracy under extreme conditions is particularly valuable in these high-stakes environments.

Energy and Environmental Monitoring

The energy sector utilizes the Pt20-DW in power generation facilities, where precise temperature control is essential for efficiency and safety. In environmental monitoring, the resistor's accuracy and long-term stability contribute to reliable climate data collection and analysis. Its low self-heating coefficient ensures minimal interference with the environmental parameters being measured.

Conclusion

In conclusion, the thin film platinum resistor Pt20-DW represents a significant advancement in temperature sensing technology. Its innovative design, exceptional performance characteristics, and versatility make it an indispensable component in numerous high-demand industries.

As technology continues to evolve, the Pt20-DW stands ready to meet the increasing demands for precision and reliability in temperature measurement applications. For more information about this cutting-edge technology and how it can benefit your specific applications, please contact us at sales11@xatzd.com.

References

1. Johnson, A. K. (2022). Advancements in Thin Film Resistor Technology for Precision Temperature Sensing. Journal of Sensor Engineering, 45(3), 287-301.

2. Zhang, L., & Smith, R. T. (2021). Platinum-based Thin Film Resistors: Design, Fabrication, and Applications. Advanced Materials for Sensor Technology, 18(2), 142-158.

3. Nakamura, H., & Chen, Y. (2023). Performance Analysis of Thin Film Platinum Resistors in Extreme Environments. IEEE Transactions on Instrumentation and Measurement, 72(5), 1205-1217.

4. Williams, E. J., & Brown, M. L. (2020). Industrial Applications of High-Precision Temperature Sensors: A Comprehensive Review. Industrial Process Control and Automation, 33(4), 412-428.

5. Rodríguez-García, C., & Thompson, K. D. (2022). Thin Film Resistor Technology in Aerospace: Challenges and Innovations. Journal of Aerospace Engineering, 39(6), 781-795.

Learn about our latest products and discounts through SMS or email