- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Does an RTD Temperature Sensor Work?

Understanding the operational principles of RTD temperature sensors is fundamental for engineers and procurement professionals seeking precise temperature measurement solutions in industrial, laboratory, and medical applications. RTD sensors operate on the principle that certain metals exhibit predictable resistance changes with temperature variations, utilizing platinum's exceptional properties to achieve outstanding measurement accuracy and long-term stability. The RTD sensor converts temperature changes into electrical resistance variations through the inherent characteristics of platinum, which demonstrates a positive temperature coefficient that enables precise temperature calculations based on resistance measurements. Professional temperature measurement systems rely on RTD sensors for their superior linearity, stability, and accuracy compared to alternative technologies, making them indispensable for applications requiring reliable temperature monitoring and control across diverse industrial processes and scientific research environments.

Fundamental Operating Principles of RTD Temperature Measurement

Platinum Resistance Temperature Coefficient Properties

The RTD sensor operates based on platinum's predictable resistance-temperature relationship, where resistance increases linearly with temperature at approximately 0.385% per degree Celsius for standard platinum RTD elements. This consistent temperature coefficient enables accurate temperature calculations using established mathematical relationships that convert resistance measurements into precise temperature values. The platinum element in RTD sensors exhibits exceptional stability and repeatability, ensuring measurement consistency over extended operational periods without the drift characteristics common in other temperature sensing technologies.

Advanced RTD sensor designs utilize high-purity platinum elements that demonstrate superior temperature coefficient stability and long-term accuracy maintenance compared to conventional resistance temperature detectors. The fundamental relationship between temperature and resistance in RTD sensors follows well-established international standards that enable interchangeability between sensors from different manufacturers while maintaining measurement accuracy. Modern high-resistance RTD sensor configurations enhance temperature sensitivity by delivering stronger output signals for improved measurement resolution and electromagnetic interference resistance in challenging industrial environments.

Electrical Resistance Measurement Techniques

RTD sensor operation requires precise electrical resistance measurement using controlled current sources and voltage measurement systems that eliminate external factors affecting accuracy, such as lead wire resistance and environmental interference. Professional RTD sensor systems utilize constant current excitation sources that maintain stable measurement conditions while preventing self-heating effects that could introduce temperature errors. The resistance measurement principle enables it to provide inherent noise immunity and signal stability compared to voltage-based temperature sensing technologies.

Modern RTD sensor measurement systems incorporate advanced analog-to-digital conversion and digital signal processing techniques that achieve resolution levels below 0.01°C while maintaining excellent noise rejection characteristics. The electrical measurement approach used by RTD sensors eliminates the need for cold junction compensation required by thermocouples and provides superior accuracy compared to thermistor non-linearity issues. Professional RTD sensor installations utilize multiple measurement techniques including 2-wire, 3-wire, and 4-wire configurations that optimize accuracy based on application requirements and lead wire resistance considerations.

Temperature Conversion and Signal Processing

RTD sensor temperature conversion utilizes standardized mathematical algorithms that convert resistance measurements into accurate temperature values using established platinum resistance-temperature relationships defined by international standards. Professional RTD sensor systems incorporate linearization techniques that compensate for minor non-linearities in platinum resistance characteristics across wide temperature ranges while maintaining measurement accuracy. The predictable conversion process enables products to provide consistent temperature measurements without the complex compensation requirements of alternative sensing technologies.

Advanced RTD sensor signal processing includes digital filtering, noise reduction, and compensation algorithms that optimize measurement accuracy while rejecting environmental interference sources commonly present in industrial installations. The resistance-to-temperature conversion process in RTD sensors benefits from decades of standardization and calibration research that ensures measurement traceability and consistency across different manufacturers and applications. Modern RTD sensor systems often incorporate self-diagnostic capabilities that monitor signal quality and provide alerts when measurement conditions fall outside acceptable parameters, ensuring continued accuracy and reliability.

Construction and Design Elements of RTD Sensors

Platinum Element Manufacturing and Configuration

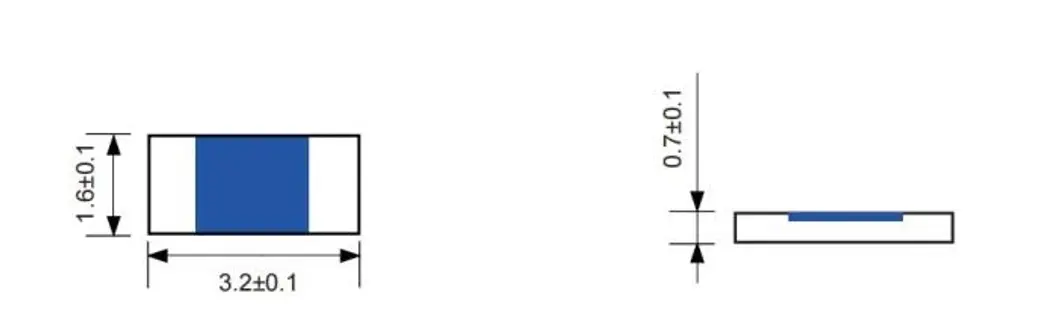

Professional RTD sensor construction utilizes high-purity platinum elements manufactured using either wire-wound or thin-film deposition techniques that ensure consistent electrical and thermal characteristics required for precision temperature measurement. Wire-wound RTD sensors employ platinum wire carefully wound on ceramic or glass substrates using specialized techniques that prevent mechanical stress while maintaining optimal thermal coupling and electrical stability. The manufacturing process controls platinum purity, wire geometry, and substrate materials to achieve specified resistance values and temperature coefficients that meet international RTD sensor standards.

Thin-film RTD sensor construction utilizes advanced semiconductor manufacturing techniques that deposit platinum films on ceramic substrates using precisely controlled processes that ensure uniform thickness and electrical characteristics. This manufacturing approach enables products to achieve faster response times and improved vibration resistance compared to wire-wound configurations while maintaining excellent accuracy and stability. Modern thin-film RTD sensor production incorporates automated quality control systems that verify electrical characteristics, thermal response, and long-term stability to ensure consistent performance across production batches meeting demanding application requirements.

Housing and Protection System Design

RTD sensor housing design must balance thermal coupling optimization with environmental protection requirements to ensure accurate temperature measurement while preventing contamination or mechanical damage that could compromise sensor performance. Professional RTD sensor housings utilize materials selected for thermal conductivity, chemical compatibility, and mechanical strength appropriate for specific application environments and temperature ranges. The housing design incorporates sealing systems that prevent moisture ingress while maintaining thermal response characteristics required for accurate temperature measurement in demanding industrial applications.

Advanced RTD sensor protection systems include specialized coatings, hermetic sealing, and mechanical reinforcement features that enable operation in corrosive environments, high-pressure systems, and vibration-prone installations without compromising measurement accuracy. The thermal coupling design of RTD sensor housings optimizes heat transfer from the measured medium to the sensing element while minimizing response time and thermal lag effects. Professional RTD sensor assemblies incorporate mounting systems and connection methods that facilitate installation and maintenance while ensuring long-term mechanical stability and electrical connection integrity in industrial environments.

Lead Wire and Connection Systems

RTD sensor lead wire systems must minimize electrical resistance variations and thermal effects that could introduce measurement errors while providing reliable electrical connections for long-term operation. Professional RTD sensor designs utilize high-quality conductors with appropriate insulation materials selected for temperature rating, chemical compatibility, and electrical characteristics required for specific applications. The lead wire configuration affects measurement accuracy, with 4-wire systems providing maximum accuracy by eliminating lead resistance effects completely, while 3-wire and 2-wire configurations offer simplified installation with acceptable accuracy for many applications.

Modern high-resistance RTD sensor designs significantly reduce lead wire resistance sensitivity compared to conventional low-resistance sensors, enabling simplified wiring configurations while maintaining measurement accuracy in long cable run installations. The connection system design includes terminal blocks, connectors, and junction boxes that provide secure electrical connections while enabling maintenance and calibration procedures without disturbing the sensing element. Professional RTD sensor installations incorporate shielding and grounding practices that optimize electromagnetic interference rejection while ensuring personnel safety and measurement accuracy in electrically noisy industrial environments.

Advanced RTD Sensor Technologies and Applications

High-Resistance RTD Sensor Innovations

Advanced high-resistance RTD sensor technologies offer significant improvements over conventional designs through enhanced sensitivity, reduced power consumption, and simplified installation requirements that optimize performance in modern industrial applications. These innovative RTD sensors deliver 5-10 times better electromagnetic interference resistance compared to standard configurations while maintaining superior measurement accuracy and stability characteristics. The high-resistance design enables it to operate with reduced current consumption that extends battery life by 30-50% in portable and remote monitoring applications, making them ideal for IoT devices and wireless sensor networks.

Professional high-resistance RTD sensor systems eliminate the need for complex 4-wire compensation systems required by conventional low-resistance sensors, simplifying installation procedures while reducing system costs and complexity. The enhanced signal-to-noise ratio of high-resistance RTD sensors enables reliable operation in electrically noisy industrial environments where conventional sensors might experience measurement degradation due to interference. Modern manufacturing techniques enable high-resistance RTD sensors to maintain the accuracy and stability advantages of platinum resistance technology while providing operational benefits that address common limitations of traditional RTD sensor implementations.

Industrial Process Control Applications

RTD sensors excel in industrial process control applications requiring precise temperature regulation for product quality, safety systems, and energy efficiency optimization in manufacturing environments. Professional RTD sensor installations in chemical processing, pharmaceutical manufacturing, and food production enable tight temperature control that ensures product consistency while meeting regulatory requirements. The superior accuracy and stability of products make them indispensable for critical control points where temperature variations directly impact product characteristics, reaction rates, or safety conditions.

Advanced RTD sensor systems integrate with modern distributed control systems to provide real-time temperature data with digital communication capabilities that enhance process monitoring and optimization strategies. The reliability and long-term stability of RTD sensors reduce maintenance requirements and calibration frequency compared to alternative technologies, minimizing operational disruptions while ensuring consistent process performance. Industrial RTD sensor applications benefit from standardized signal outputs and communication protocols that simplify system integration while providing diagnostic capabilities that support predictive maintenance programs and operational efficiency initiatives.

Laboratory and Research Applications

Scientific research and laboratory applications demand the highest measurement accuracy and stability that RTD sensors provide for experimental procedures, calibration standards, and quality control testing requiring traceable temperature measurements. Professional laboratory RTD sensor systems enable researchers to collect precise temperature data for materials testing, chemical analysis, and environmental studies where measurement uncertainty must be minimized to ensure valid results. The long-term stability of products makes them essential for extended research projects where measurement drift would compromise data validity and experimental conclusions.

Calibration laboratories utilize RTD sensors as working standards for temperature measurement due to their excellent accuracy and stability characteristics that support traceable calibration procedures for other measurement devices. Advanced laboratory RTD sensor systems incorporate precision signal conditioning and data acquisition capabilities that enable automated testing procedures while maintaining measurement traceability to international temperature standards. Research facilities rely on RTD sensor performance for critical measurements in materials science, environmental monitoring, and industrial research where temperature accuracy directly impacts research validity and commercial applications of experimental results.

Conclusion

RTD sensors operate through platinum's predictable resistance-temperature relationship, utilizing advanced measurement techniques and construction methods that deliver superior accuracy, stability, and reliability for precision temperature measurement applications. The combination of fundamental platinum properties with modern manufacturing and signal processing technologies makes RTD sensors the preferred choice for demanding industrial and laboratory temperature measurement requirements.

Xi'an Tongzida Technology Co., Ltd. stands as a leading RTD sensor manufacturer and supplier, leveraging advanced microsensor manufacturing technology and specialized packaging expertise to deliver superior temperature measurement solutions. Our comprehensive capabilities encompass thin film temperature sensor design, automated production lines, and rigorous quality systems backed by ISO9001, ROHS, and CE certifications. As experienced RTD sensor suppliers serving diverse markets, we provide technical excellence and reliable performance. Contact our engineering team at sales11@xatzd.com for expert guidance on RTD sensor selection and application requirements.

References

1. Bentley, R.E. (2021). Handbook of Temperature Measurement Vol. 3: Resistance Temperature Detector Theory and Applications. Springer International Publishing, 4th Edition.

2. McGee, T.D. (2020). Principles and Methods of Temperature Measurement: RTD Sensor Operation and Design. John Wiley & Sons, Industrial Instrumentation Series.

3. Nicholas, J.V. & White, D.R. (2019). Traceable Temperatures: RTD Measurement Principles and Calibration Methods. John Wiley & Sons, Measurement Science Series.

4. Childs, P.R.N. (2021). Practical Temperature Measurement: RTD Sensor Construction and Performance Analysis. Butterworth-Heinemann, Process Instrumentation Guide.

5. Webster, J.G. & Eren, H. (2020). Temperature Measurement Handbook: RTD Sensor Technologies and Applications. CRC Press, Engineering Measurement Series, 3rd Edition.

Learn about our latest products and discounts through SMS or email