- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Applications of Thermistors in Industrial Temperature Control

Industrial temperature control applications increasingly rely on thermistors for their exceptional sensitivity, fast response times, and cost-effective implementation across diverse manufacturing processes and automated systems. Understanding the specific applications where thermistors excel enables engineers and procurement professionals to leverage their unique characteristics for optimal temperature monitoring and control solutions in industrial environments. Thermistor sensors provide high sensitivity within limited temperature ranges, making them particularly valuable for precision control applications where rapid temperature detection and response are critical for product quality and process efficiency. The thermistor sensor demonstrates superior performance in applications requiring fast thermal response, high resolution temperature measurement, and compact sensor packaging that fits into space-constrained installations while delivering reliable temperature monitoring capabilities for industrial control systems.

Manufacturing Process Control Applications Using Thermistor Technology

Plastic Processing and Injection Molding Systems

Thermistor sensors excel in plastic processing applications where rapid temperature changes require immediate detection and control response to maintain product quality and prevent material degradation. The high sensitivity and fast response characteristics of thermistor sensors enable precise temperature monitoring in injection molding systems where temperature variations of even a few degrees can significantly impact product dimensional accuracy and material properties. Professional plastic processing equipment utilizes thermistor sensors for real-time temperature feedback that enables tight control of melt temperatures, mold temperatures, and cooling cycles that optimize production efficiency while ensuring consistent product quality.

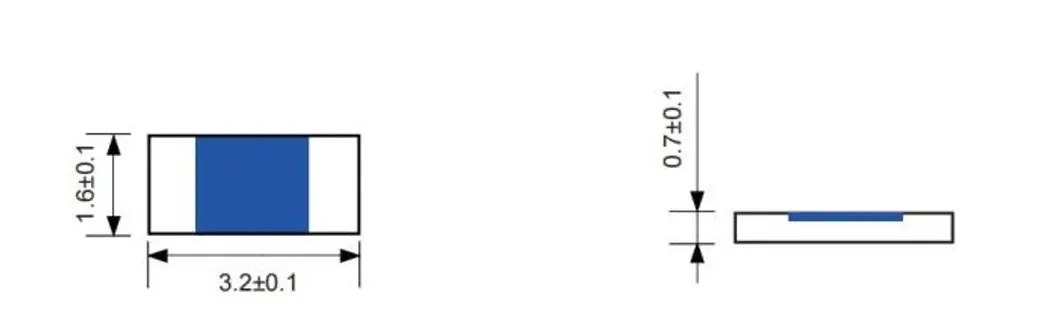

Advanced thermistor sensor implementations in injection molding systems provide temperature resolution below 0.1°C with response times under one second, enabling rapid correction of temperature deviations that could compromise product specifications. The compact size of products allows installation in confined spaces within molding equipment where larger temperature sensors would be impractical, providing temperature monitoring capabilities directly at critical control points. Modern high-resistance thermistor designs offer enhanced signal-to-noise ratios that maintain measurement accuracy even in electrically noisy industrial environments common in plastic processing facilities with high-power heating and motor control systems.

Food and Beverage Production Temperature Monitoring

Food processing industries utilize thermistor sensors for critical temperature monitoring applications including pasteurization, sterilization, and storage temperature control where precise temperature measurement ensures product safety and regulatory compliance. The fast response characteristics of thermistor sensors enable rapid detection of temperature excursions that could compromise food safety or product quality in time-sensitive processing operations. Professional food processing equipment incorporates thermistor sensors in heating, cooling, and storage systems where accurate temperature control prevents bacterial growth while maintaining optimal product characteristics and nutritional value.

Thermistor sensor applications in beverage production include fermentation temperature control, pasteurization monitoring, and cold chain management where precise temperature regulation directly impacts product taste, safety, and shelf life. The high sensitivity of thermistor sensors enables detection of small temperature variations that could indicate equipment malfunctions or process deviations requiring immediate corrective action. Advanced food processing systems utilize networks of thermistor sensors to provide comprehensive temperature monitoring throughout production facilities, enabling automated control systems to maintain optimal conditions while generating documentation required for regulatory compliance and quality assurance programs.

Chemical and Pharmaceutical Manufacturing Control

Chemical processing applications leverage thermistor sensors for reaction temperature monitoring and control where precise temperature regulation determines reaction rates, product yield, and safety conditions in manufacturing processes. The rapid response characteristics of products enable immediate detection of exothermic reactions or temperature excursions that could create dangerous conditions or compromise product quality. Professional chemical processing equipment utilizes thermistor sensors in reactor vessels, heat exchangers, and distillation systems where temperature accuracy directly impacts process efficiency and product specifications.

Pharmaceutical manufacturing processes require thermistor sensors for critical temperature monitoring in synthesis reactions, crystallization processes, and storage environments where temperature control ensures product efficacy and regulatory compliance. The high resolution capabilities of thermistor sensors enable detection of subtle temperature changes that could indicate process variations requiring immediate attention to maintain product quality standards. Modern pharmaceutical facilities implement comprehensive thermistor sensor networks that provide continuous temperature monitoring throughout manufacturing processes, enabling automated control systems to maintain optimal conditions while generating detailed documentation required for regulatory validation and quality assurance procedures.

HVAC and Environmental Control System Applications

Building Automation and Climate Control Systems

Thermistor sensors serve as primary temperature measurement devices in building automation systems where energy efficiency and occupant comfort require precise temperature monitoring and control across diverse zones and environmental conditions. The cost-effectiveness and reliability of thermistor sensors make them ideal for large-scale HVAC installations where numerous temperature measurement points are required for optimal system performance. Professional building automation systems utilize products in air handling units, zone control systems, and energy management applications where accurate temperature feedback enables efficient heating and cooling operations while minimizing energy consumption.

Advanced HVAC systems incorporate thermistor sensors with digital communication capabilities that enable integration with building management systems for comprehensive environmental monitoring and control. The compact size and versatile mounting options of thermistor sensors allow installation in ductwork, room sensors, and outdoor weather stations where reliable temperature measurement supports automated control algorithms. Modern building automation applications benefit from thermistor sensor networks that provide real-time temperature data for predictive maintenance programs and energy optimization strategies that reduce operational costs while maintaining optimal indoor environmental conditions.

Industrial Facility Environmental Monitoring

Industrial environmental monitoring systems utilize thermistor sensors for temperature measurement in manufacturing facilities, warehouses, and clean room environments where precise environmental control ensures product quality and worker safety. The sensitivity and accuracy of thermistor sensors enable detection of environmental variations that could impact sensitive manufacturing processes or storage conditions for temperature-sensitive materials. Professional environmental monitoring systems incorporate thermistor sensors in air quality monitoring, process environmental control, and safety systems where reliable temperature measurement supports regulatory compliance and operational efficiency.

Clean room applications require thermistor sensors for precise temperature and environmental control where contamination prevention and process stability demand continuous monitoring of environmental conditions. The stable performance characteristics of thermistor sensors enable long-term environmental monitoring without frequent calibration requirements, reducing maintenance costs while ensuring consistent measurement accuracy. Advanced environmental monitoring systems utilize wireless thermistor sensor networks that provide comprehensive temperature coverage throughout industrial facilities, enabling centralized monitoring and automated control responses that maintain optimal environmental conditions for sensitive manufacturing and storage applications.

Data Center and Electronic Equipment Cooling

Data center cooling systems rely on thermistor sensors for precise temperature monitoring and control in server rooms, equipment racks, and cooling distribution systems where thermal management directly impacts equipment reliability and energy efficiency. The fast response characteristics of products enable rapid detection of hot spots or cooling system failures that could damage expensive electronic equipment or cause service interruptions. Professional data center cooling systems utilize thermistor sensors in precision air conditioning units, liquid cooling systems, and equipment monitoring applications where accurate temperature measurement supports automated cooling control and energy optimization strategies.

Electronic equipment applications incorporate thermistor sensors for thermal protection and performance optimization in power supplies, motor drives, and control systems where temperature monitoring prevents overheating damage while ensuring optimal operational efficiency. The compact size of thermistor sensors enables integration directly into electronic assemblies where space constraints prevent use of larger temperature sensing devices. Modern electronic systems utilize thermistor sensors with integrated signal conditioning that provides direct digital temperature data for microprocessor-based control systems, enabling sophisticated thermal management algorithms that optimize equipment performance while preventing temperature-related failures in critical industrial applications.

Automotive and Transportation Temperature Control Applications

Engine Management and Thermal Protection Systems

Automotive applications utilize thermistor sensors extensively in engine management systems where precise temperature monitoring of coolant, oil, and air intake temperatures enables optimal engine performance while preventing thermal damage to critical components. The rugged construction and reliable performance of automotive thermistor sensors ensure accurate temperature measurement in harsh operating environments with vibration, temperature extremes, and chemical exposure. Professional automotive thermistor sensors provide temperature feedback for engine control units that optimize fuel injection, ignition timing, and emissions control based on real-time thermal conditions throughout the engine system.

Advanced automotive thermal management systems incorporate thermistor sensors in electric vehicle battery cooling, hybrid powertrain thermal control, and exhaust after-treatment systems where precise temperature monitoring ensures optimal performance and component protection. The fast response characteristics of thermistor sensors enable rapid detection of thermal transients that require immediate control system responses to prevent component damage or performance degradation. Modern automotive applications benefit from thermistor sensors with enhanced electromagnetic interference resistance that maintain measurement accuracy in electrically noisy vehicle environments with high-power electronic systems and wireless communication devices.

HVAC and Cabin Climate Control

Automotive HVAC systems utilize thermistor sensors for cabin temperature monitoring, evaporator temperature control, and automatic climate control functions where passenger comfort and system efficiency require precise temperature measurement and control. The sensitivity and accuracy of thermistor sensors enable detection of small temperature variations that support sophisticated climate control algorithms providing optimal passenger comfort while minimizing energy consumption. Professional automotive HVAC systems incorporate multiple thermistor sensors throughout air distribution systems to provide comprehensive temperature monitoring that supports zone control and automatic temperature regulation functions.

Electric and hybrid vehicle applications require thermistor sensors for battery thermal management, power electronics cooling, and cabin heating systems where thermal control directly impacts vehicle range and component longevity. The reliable performance of thermistor sensors in automotive environments ensures consistent temperature monitoring throughout vehicle operational life without frequent replacement or calibration requirements. Advanced automotive climate systems utilize products with integrated signal processing that provides direct digital temperature data for sophisticated control algorithms, enabling precise climate control while optimizing energy efficiency in conventional and electric vehicle applications.

Transportation and Logistics Temperature Monitoring

Cold chain transportation applications rely on thermistor sensors for precise temperature monitoring of refrigerated trucks, shipping containers, and storage facilities where temperature control ensures product quality and regulatory compliance for food, pharmaceutical, and chemical products. The accuracy and reliability of thermistor sensors enable continuous temperature documentation required for quality assurance and regulatory validation throughout transportation and storage processes. Professional cold chain systems utilize products with data logging capabilities that provide comprehensive temperature records supporting traceability requirements and quality control procedures.

Aviation and aerospace applications incorporate thermistor sensors for environmental control, equipment thermal monitoring, and safety systems where reliable temperature measurement supports passenger comfort and equipment protection in demanding operational environments. The proven reliability and performance characteristics of thermistor sensors make them suitable for critical applications where temperature monitoring failures could compromise safety or operational capability. Modern transportation systems benefit from wireless thermistor sensor networks that provide comprehensive temperature monitoring throughout vehicles and facilities, enabling centralized monitoring and automated control responses that maintain optimal conditions while minimizing operational costs and ensuring regulatory compliance.

Conclusion

Thermistor sensors provide exceptional value in industrial temperature control applications through their high sensitivity, fast response, and cost-effective implementation across manufacturing, HVAC, and transportation systems. Their unique characteristics make them ideal for applications requiring rapid temperature detection and precise control within moderate temperature ranges, enabling optimal process performance and energy efficiency.

Xi'an Tongzida Technology Co., Ltd. stands as a premier thermistor sensor manufacturer and supplier, leveraging advanced microsensor manufacturing technology and specialized packaging expertise to deliver superior temperature sensing solutions. Our comprehensive capabilities encompass thin film temperature sensor design, automated production lines, and rigorous quality control systems backed by ISO9001, ROHS, and CE certifications. As experienced thermistor sensor suppliers serving diverse industrial markets, we provide technical excellence and reliable performance for demanding applications. Contact our engineering team at sales11@xatzd.com for expert guidance on thermistor sensor selection and application requirements.

References

1. Fraden, J. (2020). Handbook of Modern Sensors: Physics, Designs, and Applications. Springer International Publishing, 5th Edition.

2. McGee, T.D. (2019). Principles and Methods of Temperature Measurement: Thermistor Applications in Industrial Control. John Wiley & Sons, Industrial Instrumentation Series.

3. Park, S.K. & Lee, D.H. (2021). Industrial Temperature Sensors: Thermistor Technology and Manufacturing Applications. Elsevier Science & Technology, Process Control Series.

4. Webster, J.G. & Eren, H. (2020). The Measurement, Instrumentation and Sensors Handbook: Thermistor Sensor Applications. CRC Press, 3rd Edition.

5. Wilson, J.S. (2018). Sensor Technology Handbook: Thermistors in Industrial Temperature Control Systems. Newnes, Industrial Electronics Series.

Learn about our latest products and discounts through SMS or email