- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Thermistor Sensors Work in Industrial Systems?

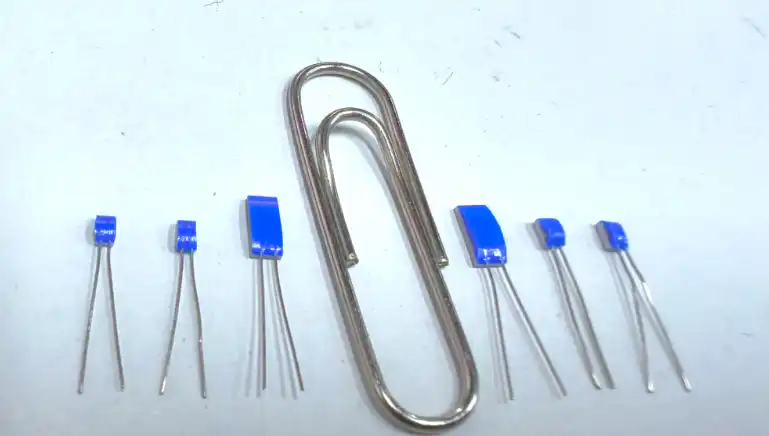

Understanding the operational principles and applications of thermistor sensors in industrial environments is essential for engineers and procurement professionals seeking efficient temperature measurement solutions for manufacturing processes, quality control systems, and automated production equipment. Industrial thermistor sensors operate through predictable resistance changes with temperature variations, providing high sensitivity measurements that enable precise process control and monitoring across diverse manufacturing applications. The product represents a cost-effective temperature measurement technology that combines fast response times, compact packaging, and excellent sensitivity characteristics ideal for industrial applications requiring rapid temperature detection and control.

Fundamental Operating Principles of Industrial Thermistor Sensors

Temperature-Resistance Relationship and Measurement Principles

Industrial thermistor sensors operate based on the predictable exponential relationship between temperature and electrical resistance in semiconductor materials, typically exhibiting negative temperature coefficients that provide high sensitivity for precise temperature measurements. Professional thermistor sensor applications utilize this nonlinear resistance characteristic through specialized signal conditioning circuits that convert resistance changes into accurate temperature readings for industrial control systems. The thermistor sensor's exponential response provides significantly higher sensitivity compared to linear sensor technologies, enabling detection of small temperature variations critical for precision manufacturing processes and quality control applications.

Advanced industrial thermistor sensor designs incorporate compensation techniques and linearization algorithms that optimize measurement accuracy while simplifying system integration and calibration procedures. Modern signal processing methods enable thermistor sensors to achieve measurement resolutions below 0.01°C within their optimal operating ranges, making them ideal for applications requiring high precision temperature control. The thermistor sensor technology offers superior signal-to-noise ratios compared to other temperature sensing methods, ensuring reliable measurements even in electrically noisy industrial environments with motor drives, power electronics, and electromagnetic interference sources that could compromise measurement quality.

Materials Science and Construction Technologies

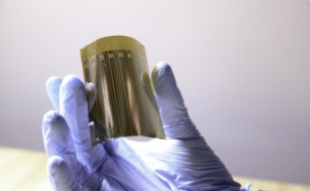

Industrial thermistor sensors utilize advanced semiconductor materials including metal oxides, ceramic compounds, and polymer composites that exhibit stable temperature-resistance characteristics optimized for specific industrial applications and environmental conditions. Professional thermistor sensor manufacturing incorporates precise material formulation, controlled sintering processes, and specialized packaging techniques that ensure consistent performance characteristics and long-term stability in demanding industrial environments. The product construction methods include thin-film deposition, thick-film printing, and bulk ceramic processing that optimize thermal response, mechanical durability, and electrical characteristics for diverse industrial applications.

Modern industrial applications benefit from thermistor sensors with enhanced electromagnetic interference resistance and improved signal strength that maintain measurement accuracy in challenging environments with high-power electrical equipment and wireless communication systems. Advanced material engineering enables thermistor sensors to operate reliably across wide temperature ranges while maintaining the sensitivity advantages that make them superior to alternative technologies for specific applications.

Signal Conditioning and Interface Electronics

Industrial thermistor sensor systems require specialized signal conditioning electronics that convert nonlinear resistance characteristics into linear temperature outputs suitable for industrial control systems and data acquisition equipment. Professional signal conditioning circuits incorporate precision reference sources, linearization algorithms, and temperature compensation techniques that optimize measurement accuracy while providing standardized output signals compatible with industrial automation systems.

Advanced signal conditioning systems for industrial thermistor sensors include digital processing capabilities, self-diagnostic features, and communication interfaces that enable integration with modern distributed control systems and industrial IoT networks. Modern electronics designs incorporate features such as automatic range selection, fault detection, and predictive maintenance capabilities that enhance system reliability while reducing maintenance requirements. The thermistor sensor signal processing technology enables intelligent measurement systems that continuously optimize performance while providing comprehensive diagnostic information supporting predictive maintenance programs and operational efficiency initiatives in industrial environments.

Industrial Applications and Process Integration

Manufacturing Process Temperature Control

Industrial thermistor sensors excel in manufacturing process control applications where rapid temperature response and high sensitivity enable precise regulation of heating, cooling, and thermal processing operations across diverse production systems. Professional manufacturing processes utilize thermistor sensors in injection molding equipment, semiconductor processing systems, and chemical reactors where temperature accuracy directly impacts product quality and production yield. The thermistor sensor's fast thermal response characteristics make it ideal for applications requiring immediate detection of temperature changes that could affect product specifications or process stability.

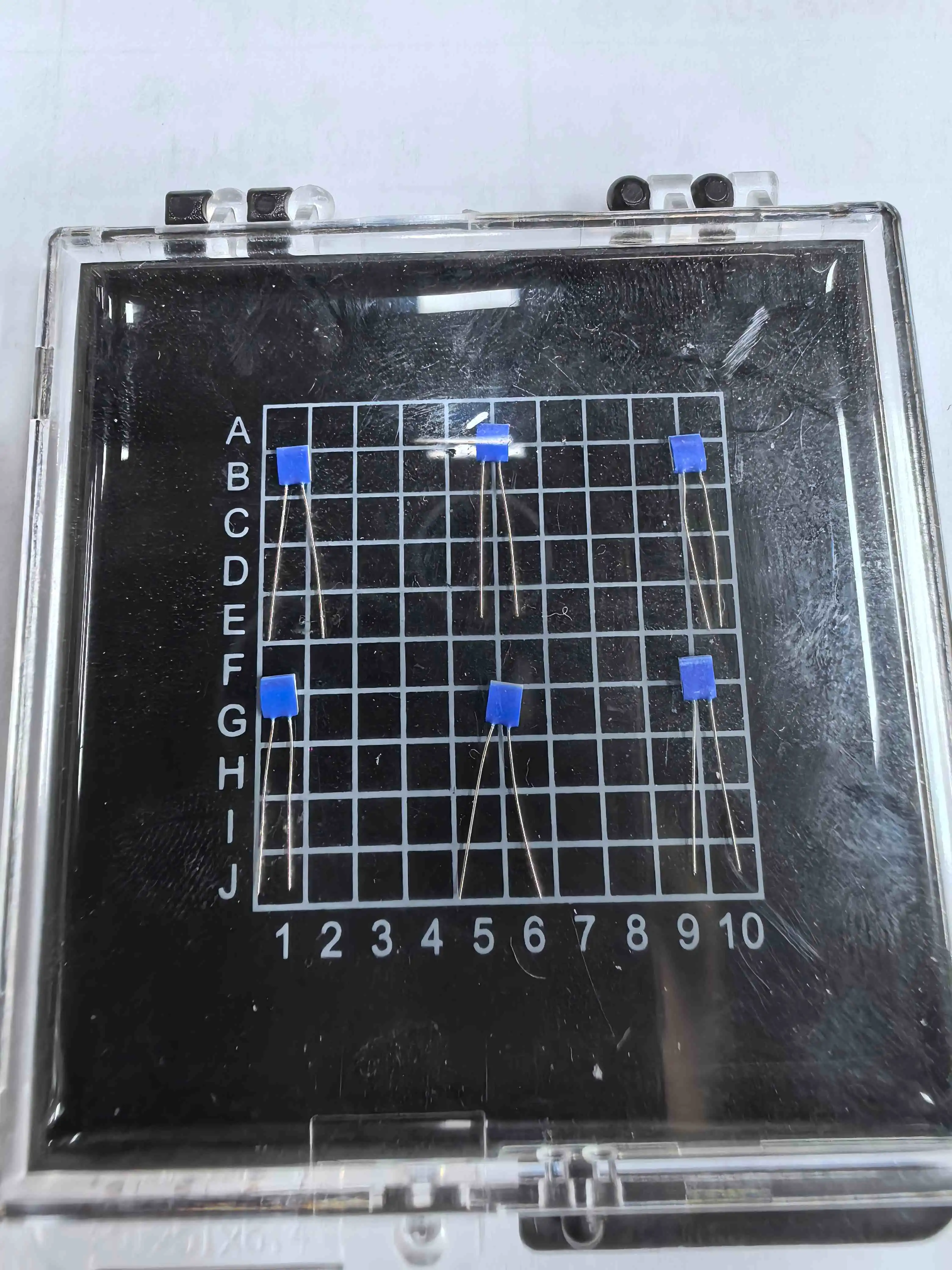

Advanced manufacturing systems incorporate networks of thermistor sensors that provide comprehensive temperature monitoring throughout production facilities, enabling automated control systems to optimize process parameters while maintaining consistent product quality. Modern industrial applications benefit from thermistor sensor integration with machine learning algorithms and predictive analytics that identify process trends and optimize operating conditions based on historical performance data.

HVAC and Environmental Control Systems

Industrial facility environmental control systems utilize thermistor sensors for precise temperature monitoring and control in manufacturing areas, clean rooms, and storage facilities where environmental conditions directly impact product quality and worker safety. Professional HVAC applications incorporate thermistor sensors in air handling units, zone control systems, and energy management applications where accurate temperature feedback enables efficient heating and cooling operations while minimizing energy consumption. The thermistor sensor's sensitivity characteristics enable detection of small environmental variations that support sophisticated control algorithms providing optimal conditions while reducing operational costs.

Modern building automation systems benefit from wireless thermistor sensor networks that provide comprehensive environmental monitoring throughout industrial facilities while minimizing installation costs and maintenance requirements. Advanced HVAC control systems incorporate it with predictive algorithms that anticipate environmental changes and adjust system operation proactively to maintain optimal conditions. The thermistor sensor technology enables energy-efficient environmental control that reduces operational costs while ensuring optimal conditions for sensitive manufacturing processes and equipment operation in demanding industrial environments.

Quality Control and Testing Applications

Industrial quality control systems employ thermistor sensors for precise temperature measurement in testing equipment, calibration systems, and validation procedures where measurement accuracy directly impacts product certification and regulatory compliance. Professional testing applications utilize thermistor sensors in thermal chambers, material testing equipment, and process validation systems where consistent temperature control ensures reliable test results and data validity. The thermistor sensor's high sensitivity enables detection of temperature variations that could compromise test accuracy or indicate equipment problems requiring immediate attention.

Advanced quality control systems incorporate thermistor sensors with automated data logging and analysis capabilities that provide comprehensive documentation supporting regulatory compliance and quality management systems. Modern testing facilities benefit from thermistor sensor integration with statistical process control software that identifies trends and patterns indicating process variations or equipment degradation. The thermistor sensor technology supports continuous improvement initiatives through detailed temperature monitoring and analysis that enables process optimization and quality enhancement in competitive manufacturing markets where consistency and reliability determine operational success.

Advanced Thermistor Technologies and System Integration

Smart Sensor Technologies and IoT Integration

Modern industrial thermistor sensors incorporate intelligent processing capabilities, wireless communication interfaces, and self-diagnostic features that enable seamless integration with Industrial IoT networks and smart manufacturing systems. Professional smart products include embedded microprocessors, adaptive calibration algorithms, and predictive maintenance capabilities that enhance measurement reliability while reducing system complexity and maintenance requirements. The thermistor sensor technology supports autonomous operation with minimal human intervention while providing comprehensive system status information and performance analytics essential for modern industrial operations.

Advanced IoT-enabled thermistor sensors utilize machine learning algorithms and cloud connectivity that enable predictive analytics, remote monitoring, and automated optimization of industrial processes based on temperature data patterns and historical performance trends. Modern industrial systems benefit from thermistor sensor networks that provide edge computing capabilities and distributed intelligence supporting real-time decision making and process optimization. The thermistor sensor integration with artificial intelligence and machine learning technologies enables intelligent manufacturing systems that continuously improve performance while reducing operational costs and maintenance requirements.

High-Performance Sensor Networks and Data Analytics

Industrial thermistor sensor networks provide comprehensive temperature monitoring throughout manufacturing facilities while utilizing advanced data analytics and visualization tools that enable proactive process management and optimization. Professional sensor network implementations incorporate redundant measurement paths, fault-tolerant communication protocols, and automated calibration verification that ensure measurement reliability and system availability in critical industrial applications. The thermistor sensor network architecture supports scalable deployment and flexible configuration that accommodates diverse industrial requirements while providing consistent performance and reliability.

Advanced data analytics platforms for thermistor sensor systems include statistical analysis tools, trend identification algorithms, and predictive modeling capabilities that identify process optimization opportunities and potential equipment problems before they impact production. Modern industrial analytics systems benefit from thermistor sensor data integration with enterprise resource planning and manufacturing execution systems that provide comprehensive operational visibility and control. The thermistor sensor technology enables data-driven decision making and continuous improvement initiatives that optimize manufacturing performance while reducing costs and improving product quality in competitive industrial markets.

Future Technologies and Development Trends

Emerging thermistor sensor technologies include advanced materials, novel construction methods, and innovative signal processing techniques that enhance performance characteristics while expanding application possibilities in next-generation industrial systems. Professional development programs focus on improving temperature range capabilities, response time characteristics, and electromagnetic interference resistance that address evolving industrial requirements for more demanding applications. The thermistor sensor technology roadmap includes integration with advanced manufacturing techniques such as additive manufacturing and nanotechnology that enable customized sensor solutions for specific industrial applications.

Future industrial thermistor sensor developments incorporate quantum sensing principles, advanced materials science, and artificial intelligence integration that promise revolutionary improvements in measurement accuracy, reliability, and functionality. Modern research initiatives explore thermistor sensor applications in emerging industrial technologies including renewable energy systems, advanced manufacturing processes, and autonomous industrial equipment. The thermistor sensor technology evolution supports next-generation industrial systems that require more sophisticated measurement capabilities while maintaining the cost-effectiveness and reliability advantages that make thermistors attractive for diverse industrial applications requiring precise temperature monitoring and control.

Conclusion

Industrial thermistor sensors work through predictable resistance-temperature relationships that provide high sensitivity measurements essential for manufacturing process control, environmental monitoring, and quality assurance applications. Their fast response characteristics, compact packaging, and cost-effective implementation make them ideal for diverse industrial systems requiring precise temperature monitoring while supporting modern IoT integration and intelligent manufacturing initiatives that optimize operational performance and efficiency.

Xi'an Tongzida Technology Co., Ltd. stands as a premier thermistor sensor manufacturer and supplier, leveraging advanced microsensor manufacturing technology and specialized packaging expertise to deliver superior temperature sensing solutions for demanding industrial applications. Our comprehensive capabilities encompass thin film temperature sensor design, automated production lines, and rigorous quality control systems backed by ISO9001, ROHS, and CE certifications. As experienced thermistor sensor suppliers serving diverse markets, we provide technical excellence and reliable performance. Contact our engineering team at sales11@xatzd.com for expert guidance on thermistor sensor selection and industrial application requirements.

References

1. Fraden, J. (2021). Handbook of Modern Sensors: Physics, Designs, and Applications - Thermistor Technologies in Industrial Systems. Springer International Publishing, 5th Edition.

2. McGee, T.D. (2020). Industrial Temperature Measurement: Thermistor Sensor Applications and System Integration. John Wiley & Sons, Industrial Instrumentation Series.

3. Park, S.K. & Williams, R.L. (2019). Thermistor Sensors in Manufacturing: Process Control and Quality Assurance Applications. Elsevier Science & Technology, Process Engineering Series.

4. Thompson, A.J. (2021). Smart Sensor Technologies: Industrial Thermistor Networks and IoT Integration. CRC Press, Industrial Electronics Series.

5. Wilson, J.S. & Chen, L.M. (2020). Sensor Technology Handbook: Thermistor Applications in Industrial Automation Systems. Newnes, Industrial Measurement Series.

Learn about our latest products and discounts through SMS or email