- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

PT100 Characteristics You Must Know for Accurate Measurement

Understanding the critical characteristics of PT100 sensors is fundamental for engineers and procurement professionals seeking to achieve maximum measurement accuracy in precision temperature monitoring applications across industrial, laboratory, and commercial systems. Professional temperature measurement success depends on comprehensive knowledge of PT100 sensor specifications, performance parameters, and operational characteristics that directly impact measurement quality and system reliability. The PT100 sensor represents the industry standard for precision temperature measurement, offering exceptional accuracy and long-term stability through carefully controlled platinum resistance characteristics and standardized construction methods. Mastering these essential characteristics enables engineers to optimize sensor selection, installation procedures, and measurement system design while avoiding common pitfalls that compromise accuracy and reliability in demanding applications where precise temperature monitoring is critical for operational success and quality assurance.

Essential Technical Specifications and Performance Parameters

Resistance-Temperature Characteristics and Accuracy Standards

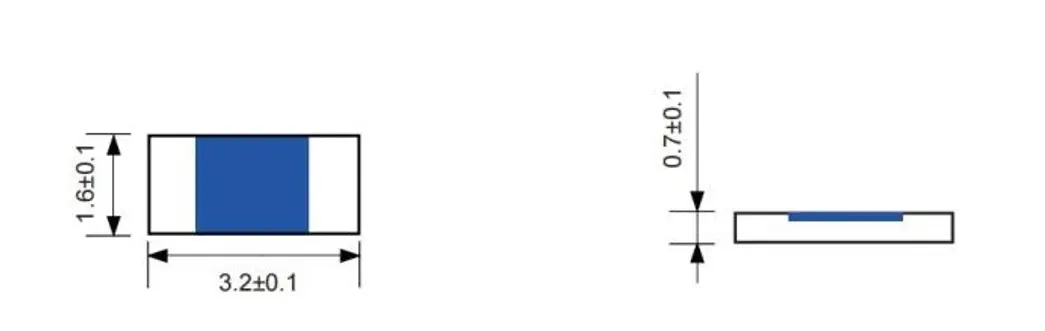

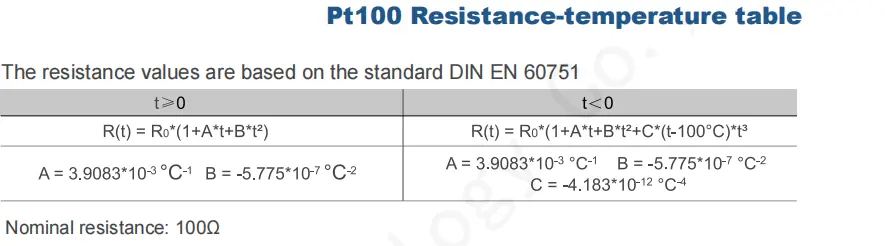

The PT100 sensor exhibits predictable resistance-temperature relationships defined by international standards, with nominal resistance values of 100 ohms at 0°C and a temperature coefficient of approximately 0.385 ohms per degree Celsius. Professional PT100 sensor applications rely on these standardized characteristics to ensure measurement accuracy and interchangeability between sensors from different manufacturers while maintaining consistent system performance. The linear relationship between temperature and resistance in PT100 sensors enables straightforward temperature calculations using established conversion algorithms that provide accurate results across wide temperature ranges.

Accuracy classifications for PT100 sensors follow international standards including IEC 60751, which defines tolerance classes ranging from AA (±0.1°C) to B (±0.3°C) that specify maximum allowable deviations from nominal resistance values. Professional applications requiring the highest accuracy typically specify Class AA PT100 sensors that provide superior measurement precision for critical control and monitoring functions. Modern high-resistance PT100 sensor designs offer enhanced accuracy through improved signal-to-noise ratios and reduced susceptibility to lead wire effects that commonly compromise measurement quality in conventional low-resistance configurations.

Temperature Range and Environmental Compatibility

Standard PT100 sensors operate effectively across temperature ranges from -200°C to +850°C, with specialized versions extending these limits for extreme applications requiring reliable performance beyond conventional operating boundaries. Professional PT100 sensor selection must consider application-specific temperature requirements and environmental conditions that affect sensor performance and operational life. The platinum element's inherent stability ensures consistent measurement accuracy throughout the specified temperature range without the drift issues commonly experienced with alternative sensor technologies.

Environmental compatibility factors for PT100 sensors include chemical resistance, mechanical durability, and thermal shock tolerance that determine suitability for specific industrial applications and operating conditions. Professional PT100 sensor installations require appropriate protective housings and sealing systems that prevent contamination while maintaining optimal thermal coupling for accurate temperature measurement. Advanced PT100 sensor designs incorporate enhanced environmental protection through specialized materials and construction techniques that extend operational life while preserving measurement accuracy in demanding applications.

Long-term Stability and Drift Characteristics

PT100 sensors demonstrate exceptional long-term stability with minimal drift over years of continuous operation, typically maintaining accuracy specifications for 5-10 years under normal operating conditions without requiring frequent recalibration. Professional applications benefit from PT100 sensor stability characteristics that reduce maintenance costs and calibration frequency compared to alternative temperature sensing technologies. The platinum resistance element's material properties ensure predictable performance degradation patterns that enable planned maintenance scheduling and sensor replacement based on established reliability data.

Drift characteristics in PT100 sensors depend on operating conditions, installation methods, and environmental factors that affect platinum element stability over time. Professional PT100 sensor monitoring programs include periodic calibration verification and performance tracking that identify gradual changes requiring attention before measurement errors compromise system performance. Modern high-resistance PT100 sensor technologies offer improved stability through enhanced electromagnetic interference resistance and reduced sensitivity to installation variables that commonly affect conventional sensor performance in industrial environments.

Installation Factors Affecting Measurement Accuracy

Wiring Configuration and Lead Resistance Effects

PT100 sensor wiring configurations significantly impact measurement accuracy, with 2-wire, 3-wire, and 4-wire connections offering different levels of precision and complexity for various application requirements. Professional installations utilize 4-wire connections for maximum accuracy by eliminating lead resistance effects completely, while 3-wire configurations provide acceptable accuracy with simplified wiring for many applications. The PT100 sensor measurement accuracy depends heavily on proper wiring implementation and lead resistance compensation techniques that prevent measurement errors from affecting system performance.

Lead resistance effects become increasingly significant in PT100 sensor installations with long cable runs or high-resistance connections that introduce measurement errors proportional to lead wire resistance values. Professional PT100 sensor installations incorporate appropriate cable selection, connection methods, and compensation techniques that minimize lead resistance effects while maintaining measurement accuracy. Advanced high-resistance PT100 sensor designs significantly reduce lead resistance sensitivity compared to conventional sensors, enabling simplified wiring configurations while maintaining precision measurement capabilities in challenging installation environments.

Thermal Coupling and Response Time Optimization

Thermal coupling design critically affects PT100 sensor response time and measurement accuracy, requiring careful balance between thermal protection and optimal heat transfer characteristics for specific applications. Professional PT100 sensor installations optimize thermal coupling through appropriate housing selection, mounting methods, and thermal interface materials that ensure rapid temperature response while protecting the sensing element. The thermal time constant of products depends on housing design, installation method, and measured medium characteristics that determine system response to temperature changes.

Response time optimization for PT100 sensors involves minimizing thermal mass while maintaining adequate mechanical protection and environmental sealing for reliable long-term operation. Professional applications requiring fast temperature response utilize specialized PT100 sensor configurations with reduced thermal mass and optimized heat transfer characteristics. Modern product designs incorporate advanced packaging techniques that achieve faster response times while maintaining the accuracy and stability advantages of platinum resistance technology in demanding measurement applications.

Environmental Protection and Mechanical Considerations

Environmental protection systems for PT100 sensors must prevent contamination, corrosion, and mechanical damage while maintaining optimal thermal coupling for accurate temperature measurement in demanding industrial applications. Professional PT100 sensor protection incorporates appropriate housing materials, sealing systems, and mounting methods that ensure reliable operation throughout specified environmental conditions. The selection of protective systems depends on chemical compatibility, temperature rating, and mechanical strength requirements for specific operating environments.

Mechanical considerations for PT100 sensor installations include vibration resistance, thermal expansion management, and mounting stress effects that can affect measurement accuracy and sensor reliability over time. Professional installation practices incorporate flexible mounting systems, stress relief techniques, and vibration isolation methods that prevent mechanical effects from compromising PT100 sensor performance. Advanced sensor designs include enhanced mechanical construction and mounting systems that resist environmental stresses while maintaining measurement accuracy in challenging industrial applications.

Signal Conditioning and System Integration Requirements

Electronic Interface and Signal Processing

PT100 sensor signal conditioning requires precision electronics that convert resistance measurements into accurate temperature values while providing appropriate amplification, linearization, and noise rejection for reliable system integration. Professional signal conditioning systems incorporate constant current sources, precision amplifiers, and analog-to-digital converters that optimize measurement accuracy while minimizing environmental interference effects. The PT100 sensor interface design must account for lead resistance compensation, electromagnetic interference rejection, and calibration requirements that ensure reliable operation in industrial environments.

Modern PT100 sensor signal processing includes digital filtering, automatic range selection, and self-diagnostic capabilities that enhance measurement reliability while simplifying system integration and maintenance procedures. Advanced signal conditioning systems incorporate features such as sensor fault detection, drift compensation, and predictive maintenance algorithms that optimize PT100 sensor performance while providing comprehensive system status information. These intelligent signal processing capabilities enable PT100 sensors to deliver superior measurement accuracy while supporting modern industrial automation and control system requirements.

Calibration and Verification Procedures

PT100 sensor calibration procedures ensure measurement traceability and accuracy through systematic comparison with certified temperature standards and documentation of sensor performance characteristics. Professional calibration programs incorporate appropriate reference standards, testing equipment, and procedures that verify PT100 sensor accuracy across specified temperature ranges while maintaining measurement traceability to international standards. The calibration process must account for measurement uncertainty, environmental conditions, and system-specific factors that affect overall measurement accuracy.

Verification procedures for PT100 sensors include resistance measurements at known temperatures, insulation testing, and response time evaluation that confirm proper sensor operation and identify potential problems requiring corrective action. Professional verification programs utilize automated testing equipment and standardized procedures that ensure consistent results while minimizing testing time and operator error. Modern PT100 sensor systems often incorporate self-calibration capabilities and continuous performance monitoring that reduce manual calibration requirements while maintaining measurement accuracy and reliability.

Data Communication and System Integration

Modern PT100 sensor systems incorporate digital communication interfaces that enable seamless integration with industrial control systems, data acquisition equipment, and monitoring networks while providing enhanced diagnostic capabilities. Professional communication systems utilize standardized protocols including Modbus, HART, and Ethernet that simplify system integration while providing comprehensive sensor status and performance information. The PT100 sensor communication design must ensure data integrity, security, and reliability while supporting real-time measurement and control requirements.

Advanced PT100 sensor integration includes wireless communication capabilities, edge computing functions, and cloud connectivity that enable remote monitoring and predictive maintenance programs while reducing installation complexity and maintenance requirements. Modern sensor networks incorporate mesh communication, data encryption, and automated configuration that optimize system performance while providing scalable deployment options for diverse applications. These advanced communication capabilities enable PT100 sensors to support Industry 4.0 initiatives and intelligent manufacturing systems that require sophisticated measurement and control capabilities.

Conclusion

PT100 sensor characteristics including resistance-temperature relationships, accuracy classifications, environmental compatibility, and installation requirements are fundamental to achieving accurate temperature measurements. Understanding these critical parameters enables engineers to optimize sensor selection, installation procedures, and system integration while avoiding common pitfalls that compromise measurement quality and reliability in precision temperature monitoring applications.

Xi'an Tongzida Technology Co., Ltd. stands as a leading PT100 sensor manufacturer and supplier, leveraging advanced microsensor manufacturing technology and specialized packaging expertise to deliver superior temperature measurement solutions with comprehensive technical support. Our extensive capabilities encompass thin film temperature sensor design, automated production lines, and rigorous quality control systems backed by ISO9001, ROHS, and CE certifications. Contact our engineering team at sales11@xatzd.com for expert guidance on PT100 sensor characteristics and application requirements.

References

1. Bentley, R.E. (2021). Handbook of Temperature Measurement Vol. 3: PT100 Sensor Characteristics and Measurement Accuracy. Springer International Publishing, 4th Edition.

2. McGee, T.D. (2020). Precision Temperature Measurement: PT100 Sensor Specifications and Performance Analysis. John Wiley & Sons, Industrial Instrumentation Series.

3. Nicholas, J.V. & White, D.R. (2019). Traceable Temperatures: PT100 Sensor Standards and Calibration Methods. John Wiley & Sons, Measurement Science Series.

4. Webster, J.G. & Eren, H. (2021). The Measurement, Instrumentation and Sensors Handbook: PT100 Sensor Characteristics Guide. CRC Press, 3rd Edition.

5. Wilson, J.S. (2020). Sensor Technology Handbook: PT100 Performance Parameters and Application Guidelines. Newnes, Industrial Electronics Series.

Learn about our latest products and discounts through SMS or email