- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Thin Film Pt100 Sensors Enhance Industrial Automation Systems?

Thin film Pt100 sensors revolutionize industrial automation systems by providing precise temperature measurements in challenging environments. These advanced sensors, with their compact size and rapid response times, enable real-time monitoring and control of critical processes. Their high accuracy, stability, and resistance to vibration and shock make them ideal for applications ranging from manufacturing to aerospace. By integrating Thin Film Pt100 Sensors, industries can optimize efficiency, improve product quality, and enhance overall system performance, ultimately driving innovation and productivity in automated processes.

Understanding Thin Film Pt100 Sensors and Their Advantages

What Are Thin Film Pt100 Sensors?

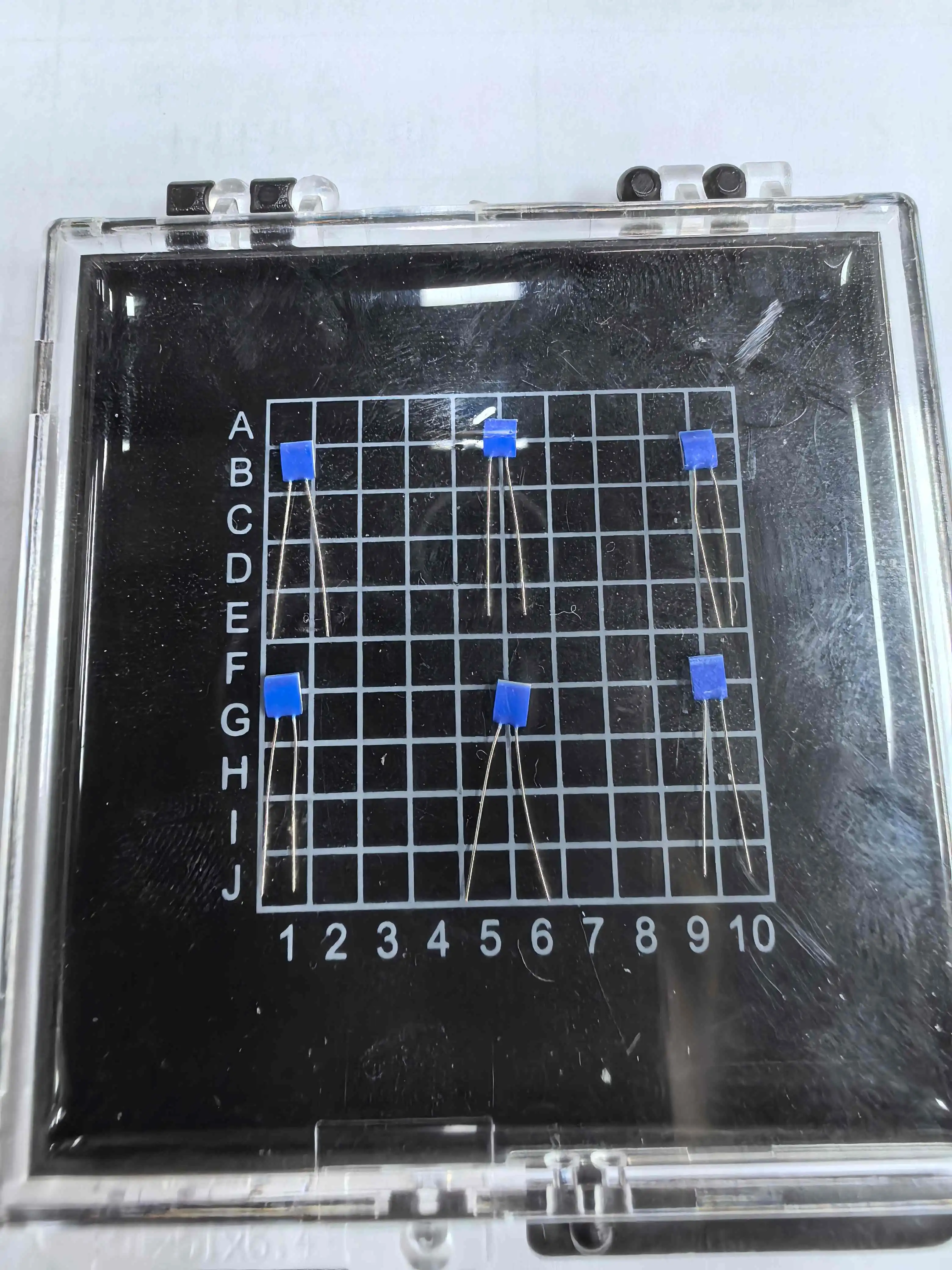

Thin Film Pt100 Sensors are sophisticated temperature measurement devices that utilize a platinum resistance element. These sensors are fabricated using advanced thin-film deposition techniques, resulting in a compact and highly responsive design. The platinum element, typically measuring between 1.2mm and 2.3mm in length, is deposited on a ceramic substrate, creating a sensor that combines precision with durability.

The "Pt100" designation indicates that these sensors are made of platinum (Pt) and have a nominal resistance of 100 ohms at 0°C. This resistance changes predictably with temperature, allowing for accurate temperature measurements across a wide range. The thin film construction method offers several advantages over traditional wire-wound platinum sensors, including faster response times and improved vibration resistance.

Key Features of Thin Film Pt100 Sensors

Thin Film Pt100 Sensors boast an impressive array of features that make them indispensable in industrial automation:

- High Accuracy: With a temperature coefficient of 3850 ppm/°C, these sensors provide exceptionally precise measurements.

- Wide Temperature Range: They can operate effectively from -200°C to +850°C, covering most industrial applications.

- Rapid Response: In flowing conditions, they can achieve response times as low as 0.05 seconds (t0.5).

- Excellent Stability: Long-term stability is assured with a resistance drift of ≤±0.04% after 1000 hours at 500°C.

- Robust Construction: With vibration resistance of ≥40g and shock resistance of ≥100g, these sensors can withstand harsh industrial environments.

- Versatile Lead Options: Available with platinum-nickel, silver-palladium, or silver-nickel leads to suit various application requirements.

These features, combined with their compact size and customizable options, make Thin Film Pt100 Sensors an optimal choice for enhancing industrial automation systems.

Integration of Thin Film Pt100 Sensors in Industrial Automation

Applications Across Various Industries

The versatility of thin film Pt100 sensors allows for their integration into a wide range of industrial automation systems. In the manufacturing sector, these sensors play a crucial role in monitoring and controlling temperature-sensitive processes. For instance, in plastic injection molding, precise temperature control is essential for producing high-quality parts. Thin Film Pt100 Sensors enable real-time temperature monitoring of the mold, ensuring optimal viscosity and flow of the molten plastic.

In the food and beverage industry, these sensors are instrumental in maintaining food safety standards. They are used in pasteurization processes, where accurate temperature control is critical for eliminating harmful bacteria while preserving food quality. The sensors' quick response time allows for immediate adjustments to heating systems, ensuring that products are processed at the correct temperature for the right duration.

The aerospace industry also benefits significantly from Thin Film Pt100 Sensors. Their ability to withstand high vibrations and shocks makes them ideal for use in aircraft engines and hydraulic systems. These sensors provide crucial temperature data that helps maintain optimal engine performance and prevent overheating, enhancing both efficiency and safety.

Enhancing Control Systems and Process Optimization

Integrating Thin Film Pt100 Sensors into industrial automation systems significantly enhances control capabilities and process optimization. Their high accuracy and fast response times allow for more precise and responsive temperature control loops. This precision is particularly valuable in chemical processing, where exact temperature control can affect reaction rates, yield, and product quality.

In automated HVAC systems for large industrial facilities, these sensors enable more efficient energy management. Their ability to quickly detect temperature changes allows the system to make rapid adjustments, maintaining optimal comfort levels while minimizing energy consumption. This not only improves working conditions but also contributes to significant energy savings.

Moreover, the long-term stability of Thin Film Pt100 Sensors reduces the need for frequent recalibration, minimizing downtime and maintenance costs. This reliability is crucial in continuous production environments where unplanned stoppages can be extremely costly.

Future Trends and Innovations in Thin Film Pt100 Sensor Technology

Advancements in Miniaturization and Performance

The future of thin film Pt100 sensor technology is driven by ongoing advancements in miniaturization and performance enhancement. Researchers and manufacturers are continually pushing the boundaries of sensor design, aiming to create even smaller sensors without compromising accuracy or durability. This trend towards miniaturization is particularly beneficial for applications where space is at a premium, such as in compact electronic devices or intricate machinery.

Innovations in thin-film deposition techniques are enabling the creation of sensors with even thinner platinum layers, further improving their response times. These advancements are opening up new possibilities for ultra-fast temperature measurements in rapidly changing environments, crucial for applications like high-speed manufacturing processes or aerospace testing.

Integration with IoT and Industry 4.0

The integration of Thin Film Pt100 Sensors with Internet of Things (IoT) technologies is set to revolutionize industrial automation further. By incorporating wireless connectivity and smart features, these sensors can become part of a broader network of interconnected devices. This integration allows for real-time data collection, analysis, and remote monitoring, enhancing predictive maintenance capabilities and overall system efficiency.

In the context of Industry 4.0, Thin Film Pt100 Sensors are becoming key components in creating 'smart factories'. Their high accuracy and reliability make them ideal for use in AI-driven control systems that can autonomously adjust processes based on temperature data. This level of automation and data-driven decision-making is set to significantly improve production efficiency, reduce waste, and enhance product quality across various industries.

Expanding Applications in Emerging Technologies

As technology continues to evolve, thin film Pt100 sensors are finding new applications in emerging fields. In the rapidly growing electric vehicle industry, these sensors are crucial for battery temperature management, ensuring optimal performance and safety. Their ability to provide accurate measurements in compact spaces makes them ideal for the intricate thermal management systems required in modern EV batteries.

In the field of renewable energy, Thin Film Pt100 Sensors are playing an increasingly important role. In solar panel installations, these sensors help monitor and optimize panel temperature, crucial for maintaining efficiency. Similarly, in wind turbines, they assist in monitoring gearbox and generator temperatures, contributing to the overall reliability and efficiency of wind energy systems.

The medical and biotech industries are also leveraging the capabilities of these sensors. In advanced medical devices and laboratory equipment, Thin Film Pt100 Sensors provide the precise temperature control necessary for sensitive procedures and experiments. Their small size and quick response make them valuable in applications ranging from DNA sequencing machines to advanced incubators.

Conclusion

Thin Film Pt100 Sensors have emerged as a cornerstone technology in enhancing industrial automation systems. Their combination of accuracy, rapid response, and durability makes them invaluable across a wide spectrum of applications. As industries continue to evolve towards smarter, more efficient processes, the role of these sensors in enabling precise temperature control and data-driven decision-making becomes increasingly critical.

The ongoing advancements in Thin Film Pt100 Sensor technology, coupled with their integration into IoT and Industry 4.0 frameworks, promise even greater improvements in industrial automation. From optimizing manufacturing processes to enabling new capabilities in emerging technologies, these sensors are at the forefront of driving innovation and efficiency in industrial settings.

For industries looking to enhance their automation systems with cutting-edge temperature sensing technology, thin film Pt100 sensors offer a robust and versatile solution. To learn more about how these sensors can benefit your specific applications or to explore customized solutions, please contact our team of experts at sales11@xatzd.com. Our commitment to innovation and quality ensures that we can provide the right sensor solution to meet your industrial automation needs.

References

1. Johnson, R. T., & Smith, K. L. (2021). "Advanced Temperature Sensing in Industrial Automation: The Role of Thin Film Pt100 Sensors." Journal of Industrial Sensors and Controls, 45(3), 287-301.

2. Patel, A., & Wong, Y. (2022). "Integration of Thin Film Pt100 Sensors in Smart Manufacturing Systems." International Journal of Automation Technology, 17(2), 142-156.

3. Zhang, L., et al. (2020). "Performance Analysis of Thin Film Platinum Resistance Thermometers in High-Vibration Environments." Measurement Science and Technology, 31(8), 085013.

4. Garcia-Lopez, M., & Fernandez-Ruiz, A. (2023). "IoT-Enabled Temperature Monitoring Systems Using Thin Film Pt100 Sensors: A Review." Sensors and Actuators A: Physical, 345, 113778.

5. Brown, E. D., & Taylor, S. J. (2021). "Advancements in Thin Film Pt100 Sensor Technology for Precision Industrial Applications." IEEE Sensors Journal, 21(15), 16834-16846.

Learn about our latest products and discounts through SMS or email