Understanding Fixed Thread Type Thermistor Temperature Sensors

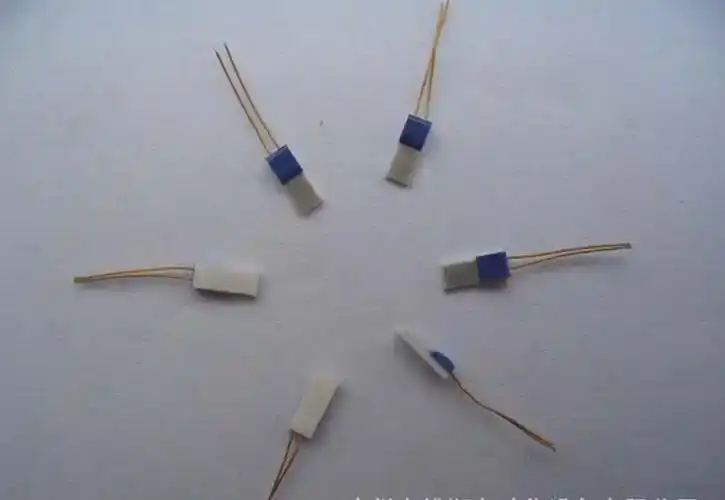

Fixed Thread Type Thermistor Temperature Sensors are specialized devices designed for precise temperature measurements in various industrial and scientific applications. These sensors utilize a thermistor, a type of resistor whose resistance varies significantly with temperature changes. The "fixed thread" design allows for easy installation and secure mounting in a wide range of environments.

Key Features and Specifications

Fixed thread type thermistor temperature sensors boast several notable features. They often come with different resistance values, such as Pt100, Pt1000, and Pt500, catering to diverse measurement needs. The wire configuration can vary between two-wire, three-wire, and four-wire systems, each offering different levels of accuracy and noise resistance.

Lead wire materials play a crucial role in sensor performance and durability. Common options include FEP (Fluorinated Ethylene Propylene), Silicone Rubber, PTFE (Polytetrafluoroethylene), PVC (Polyvinyl Chloride), and Metal Braided High-Temperature Wire. Each material offers unique properties suitable for specific environmental conditions.

The temperature coefficient, typically around 3850 ppm/K for platinum-based sensors, indicates the sensor's sensitivity to temperature changes. The self-heating coefficient, often around 0.4 K/mW at 0°C, is another crucial parameter that affects measurement accuracy.

Accuracy Classes and Operating Parameters

Fixed Thread Type Thermistor Temperature Sensors come in various accuracy classes, ranging from the highly precise 1/30B Class (tolerance ≤ ±0.01°C from 0 to 100°C) to the more general B Class (tolerance ≤ ±0.30°C from -70 to 300°C). The choice of accuracy class depends on the specific requirements of the application.

Operating current varies based on the sensor's resistance value. For instance, 100Ω sensors typically operate between 0.3 to 1 mA, while 1000Ω sensors function optimally between 0.1 to 0.3 mA. The insulation resistance (≥100 MΩ @ 500 V and 20°C) and pressure resistance standard (≥0.5 MPa) further define the sensor's operational limits and durability.

Calibration Process for Thermistor Temperature Sensors

Calibrating a fixed thread type thermistor temperature sensor is a meticulous process that ensures the device provides accurate temperature readings across its entire operating range. This procedure is essential for maintaining the sensor's reliability and performance over time.

Preparation and Equipment

Before beginning the calibration process, it's crucial to gather the necessary equipment. This typically includes a calibration bath or dry-well calibrator capable of achieving stable temperatures across the sensor's operating range, a reference thermometer with higher accuracy than the sensor being calibrated, and appropriate data logging equipment.

The sensor should be cleaned and inspected for any physical damage or wear that might affect its performance. It's also important to ensure that the sensor has been allowed to stabilize at room temperature before beginning the calibration process.

Step-by-Step Calibration Procedure

The calibration process generally involves the following steps:

- Set up the calibration bath or dry-well calibrator and allow it to stabilize at the lowest temperature point in the calibration range.

- Insert both the sensor being calibrated and the reference thermometer into the calibration environment, ensuring they are at the same depth and experiencing the same temperature.

- Allow sufficient time for both devices to stabilize at the set temperature.

- Record the readings from both the sensor and the reference thermometer.

- Repeat this process at several temperature points across the sensor's operating range, typically including the minimum, maximum, and several intermediate points.

- Compare the sensor's readings to those of the reference thermometer at each point.

- Calculate the deviation at each point and determine if it falls within the sensor's specified accuracy class.

If the sensor's readings fall outside the specified tolerance at any point, adjustments may be necessary. Some sensors allow for electronic adjustment, while others may require physical adjustment or replacement.

Post-Calibration Procedures

After completing the calibration process, it's essential to document the results thoroughly. This documentation should include the pre-calibration and post-calibration readings, any adjustments made, and the environmental conditions during calibration. A new calibration certificate should be issued, detailing the sensor's performance across its operating range.

It's also crucial to establish a calibration schedule based on the sensor's usage, environment, and criticality. Regular calibration ensures ongoing accuracy and reliability of the fixed thread type thermistor temperature sensor.

Advanced Considerations in Thermistor Sensor Calibration

While the basic calibration process is straightforward, there are several advanced considerations that can enhance the accuracy and reliability of Fixed Thread Type Thermistor Temperature Sensors.

Hysteresis and Drift Compensation

Thermistor sensors may exhibit hysteresis, where the sensor's reading depends not only on the current temperature but also on its recent temperature history. To account for this, calibration procedures often include both ascending and descending temperature cycles. By averaging the readings from both cycles, the effects of hysteresis can be minimized.

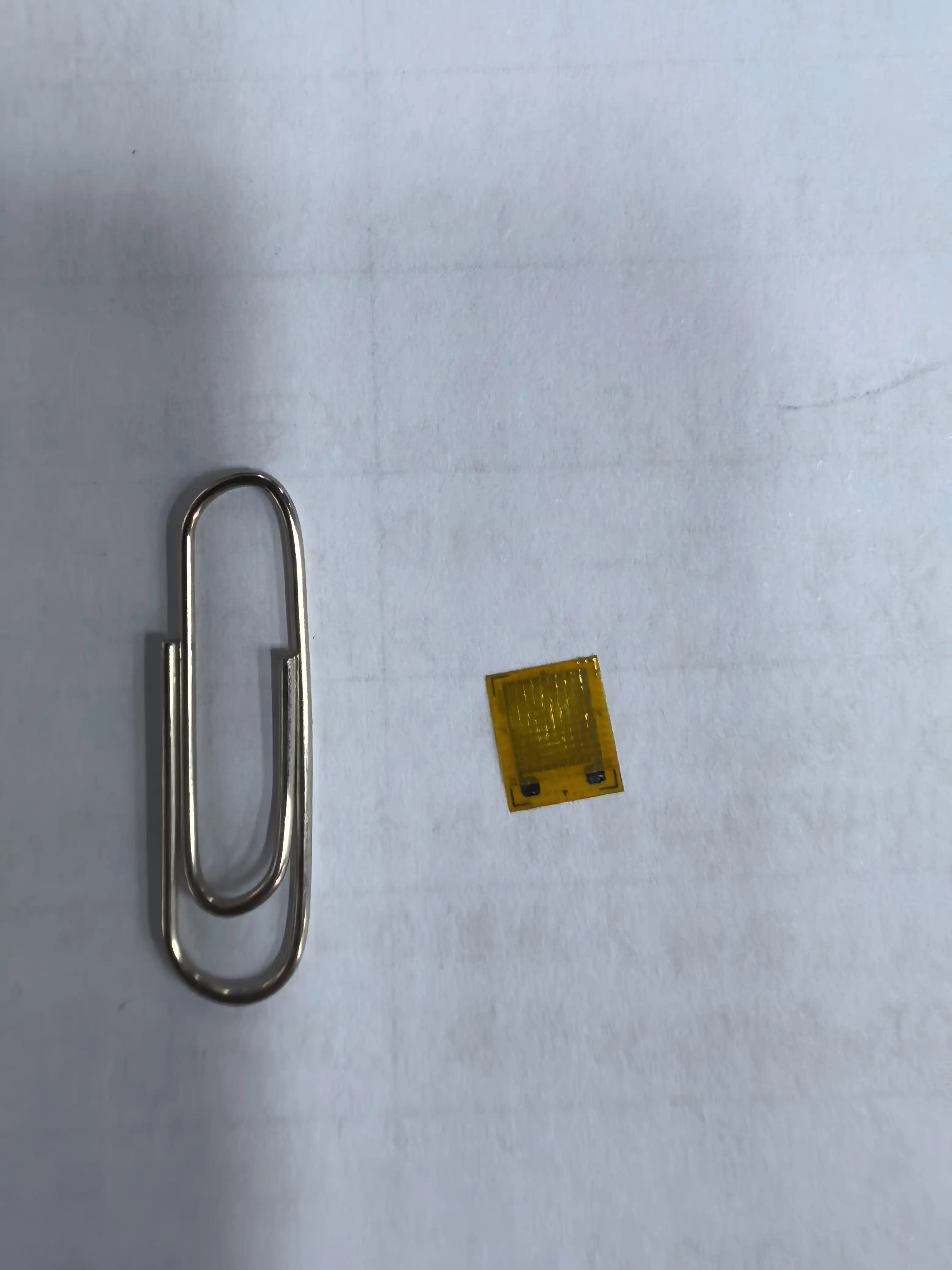

Sensor drift over time is another factor to consider. Long-term stability tests can help quantify this drift, allowing for more accurate predictions of when recalibration will be necessary. For instance, our thin film platinum resistor series boasts a long-term stability drift of ≤ 0.04%, ensuring reliable measurements over extended periods.

Environmental Factors and In-Situ Calibration

The environment in which a Fixed Thread Type Thermistor Temperature Sensor operates can significantly impact its performance. Factors such as humidity, pressure, and electromagnetic interference can all affect sensor readings. In some cases, in-situ calibration, where the sensor is calibrated in its actual operating environment, may be necessary to achieve the highest accuracy.

For sensors used in extreme conditions, such as high-temperature environments up to 850°C or ultra-low temperatures down to -200°C, specialized calibration equipment and procedures may be required. Our automated production line for thin film temperature sensor chips is equipped to handle these extreme temperature ranges, ensuring accurate calibration across a wide spectrum of applications.

Traceability and Uncertainty Analysis

For applications requiring the highest level of accuracy, such as in medical or aerospace industries, traceability to national or international standards is crucial. This involves using reference thermometers that are themselves calibrated against primary standards, creating an unbroken chain of comparisons.

Uncertainty analysis is another advanced aspect of calibration. This involves quantifying all sources of uncertainty in the calibration process, including the uncertainty of the reference thermometer, environmental variations, and the resolution of the measuring equipment. The result is a comprehensive understanding of the sensor's accuracy, expressed as a measurement uncertainty.

Our sensors, compliant with the IEC60751 standard and offering accuracies as high as ± 0.01 Ω, are suitable for these high-precision applications. With features like a rapid response time of up to 0.05 seconds and high vibration resistance of 40g, these sensors meet the demanding requirements of industrial, medical, automotive, and aerospace sectors.

Conclusion

Calibrating fixed thread type thermistor temperature sensors is a critical process that ensures accurate and reliable temperature measurements across various applications. From understanding the basic principles to considering advanced factors like hysteresis and environmental impacts, proper calibration is key to maximizing the performance of these sophisticated sensors.

Regular calibration, coupled with the use of high-quality sensors like our thin film platinum resistor series, can significantly enhance the accuracy and reliability of temperature measurements in your applications. Whether you're working in industrial processes, medical equipment, automotive systems, or aerospace technology, properly calibrated thermistor sensors are indispensable tools for precise temperature control and monitoring.

For more information about our Fixed Thread Type Thermistor Temperature Sensors, calibration services, or to discuss your specific temperature measurement needs, please don't hesitate to contact us at sales11@xatzd.com. Our team of experts is ready to help you achieve the highest standards of temperature measurement accuracy in your applications.