Understanding Flexible Thermal Sensors: Design and Functionality

Flexible thermal sensors represent a cutting-edge technology in temperature measurement, offering versatility and adaptability across various industries. These sensors, often constructed using thin-film technology, can conform to curved or irregular surfaces, making them ideal for applications where traditional rigid sensors fall short.

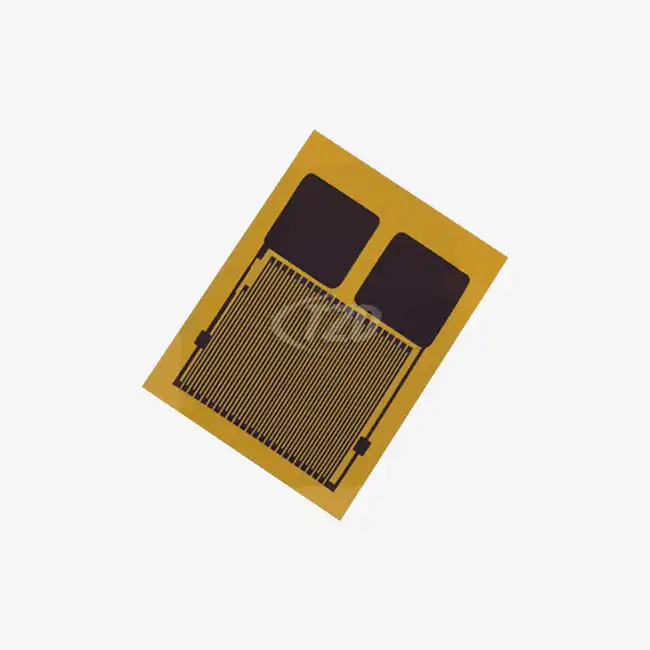

The design of flexible thermal sensors typically involves a temperature-sensitive element, such as platinum or nickel, deposited on a flexible substrate. This configuration allows for a quick response to temperature changes while maintaining the ability to bend and flex without compromising performance. The temperature coefficient of resistance (TCR) is a crucial parameter, with values like 6444 ppm/°C indicating high sensitivity to temperature variations.

Functionality-wise, these sensors operate on the principle of resistance change with temperature. As the ambient temperature fluctuates, the electrical resistance of the sensor element changes proportionally, allowing for precise temperature measurements. The temperature range of -70°C to +200°C demonstrates the wide operational scope of these sensors, making them suitable for diverse environments.

Key Components and Their Roles

The efficacy of flexible thermal sensors hinges on several key components:

- Sensing Element: Typically made of materials like platinum or nickel, chosen for their linear temperature-resistance relationship.

- Flexible Substrate: Provides the base for the sensor, allowing it to conform to various shapes.

- Protective Coating: Shields the sensing element from environmental factors, enhancing durability.

- Connection Leads: Facilitate the integration of the sensor into measurement circuits.

Understanding these components and their interplay is crucial for maintaining sensor stability over time. The choice of materials, especially for the sensing element and substrate, significantly impacts the sensor's long-term performance and reliability.

Factors Affecting Long-Term Stability of Flexible Thermal Sensors

The longevity and consistent performance of flexible thermal sensors are influenced by various factors. Recognizing and addressing these elements is crucial for ensuring the sensors maintain their accuracy and reliability over extended periods.

Environmental Challenges

Flexible thermal sensors often operate in demanding environments, facing challenges such as:

- Temperature Extremes: Exposure to temperatures beyond the specified range (-70°C to +200°C) can lead to sensor degradation.

- Humidity and Moisture: These can cause corrosion or short circuits, particularly if the sensor's protective coating is compromised.

- Mechanical Stress: Repeated bending or vibration (up to 40g) can affect the sensor's structural integrity over time.

- Chemical Exposure: Certain chemicals can degrade the sensor materials, impacting performance.

Material Degradation and Drift

The materials used in flexible thermal sensors can experience changes over time, affecting stability:

- Thermal Cycling: Repeated heating and cooling can cause microscopic changes in the sensor structure.

- Oxidation: Especially relevant for metallic sensing elements, potentially altering their electrical properties.

- Substrate Aging: The flexible substrate may experience physical changes, affecting sensor geometry.

These factors can lead to sensor drift, where the relationship between temperature and resistance gradually shifts, compromising measurement accuracy. Understanding these challenges is the first step in developing strategies to mitigate their effects and ensure long-term sensor stability.

Strategies for Enhancing Long-Term Stability

Ensuring the long-term stability of flexible thermal sensors requires a comprehensive approach, combining advanced manufacturing techniques, careful material selection, and ongoing maintenance strategies.

Advanced Manufacturing and Quality Control

The foundation of sensor stability begins with the manufacturing process:

- Precision Thin-Film Deposition: Utilizing advanced techniques for depositing the sensing element ensures uniformity and adherence to specifications.

- Rigorous Quality Control: Implementing stringent testing protocols, including vibration resistance up to 40g and impact resistance of 100g, ensures only high-quality sensors reach the market.

- Automated Production Lines: As employed by companies like Xi'an Tongzida Technology Co., Ltd., automated production minimizes human error and ensures consistency across batches.

Material Selection and Protective Measures

Choosing the right materials and implementing protective measures significantly enhances sensor longevity:

- High-Grade Sensing Elements: Using platinum or other materials with stable temperature coefficients (e.g., 3850ppm/℃) ensures consistent performance over time.

- Durable Flexible Substrates: Selecting substrates that maintain their properties over a wide temperature range (-200℃ to +850℃) is crucial for long-term stability.

- Advanced Encapsulation: Applying protective coatings that shield the sensor from environmental factors without impeding its flexibility or response time.

Calibration and Compensation Techniques

Regular calibration and the implementation of compensation algorithms are vital for maintaining accuracy:

- Periodic Recalibration: Establishing a schedule for sensor recalibration helps identify and correct drift over time.

- Digital Compensation: Implementing software algorithms that account for known drift patterns can extend the periods between physical recalibrations.

- Temperature Cycling: Subjecting sensors to controlled temperature cycles during manufacturing can help stabilize their properties, reducing initial drift.

By adopting these strategies, manufacturers and users of flexible thermal sensors can significantly enhance their long-term stability, ensuring reliable temperature measurements across diverse applications and environments.

Conclusion

The long-term stability of flexible thermal sensors is a critical factor in their effectiveness across various industries, from medical applications to aerospace. By understanding the challenges these sensors face and implementing comprehensive strategies to address them, we can ensure their reliability and accuracy over extended periods. From advanced manufacturing techniques to careful material selection and ongoing maintenance, each aspect plays a crucial role in enhancing sensor longevity.

As technology continues to evolve, so too will the methods for improving sensor stability. Staying informed about the latest advancements and best practices in this field is essential for anyone working with or relying on flexible thermal sensors. For more information on cutting-edge sensor technologies and how they can benefit your applications, please contact us at sales11@xatzd.com. Our team of experts is ready to assist you in finding the perfect sensor solution for your needs, ensuring long-term stability and performance.