- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to choose PT1000 platinum thermistor? Comprehensive guide to assist you in precise selection

How to choose PT1000 platinum thermistor? Comprehensive guide to assist you in precise selection

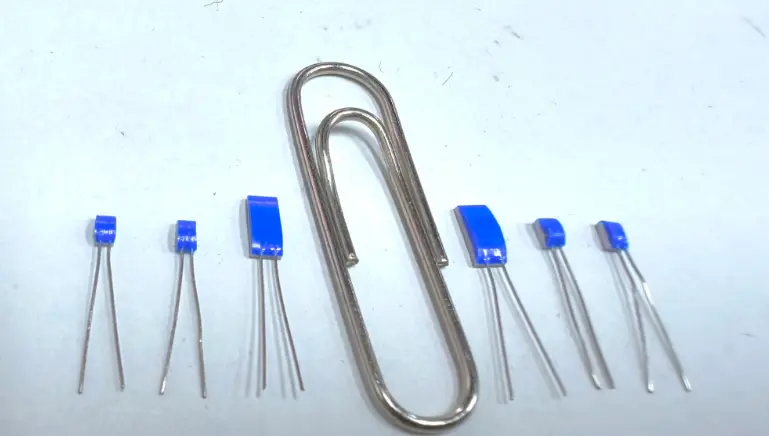

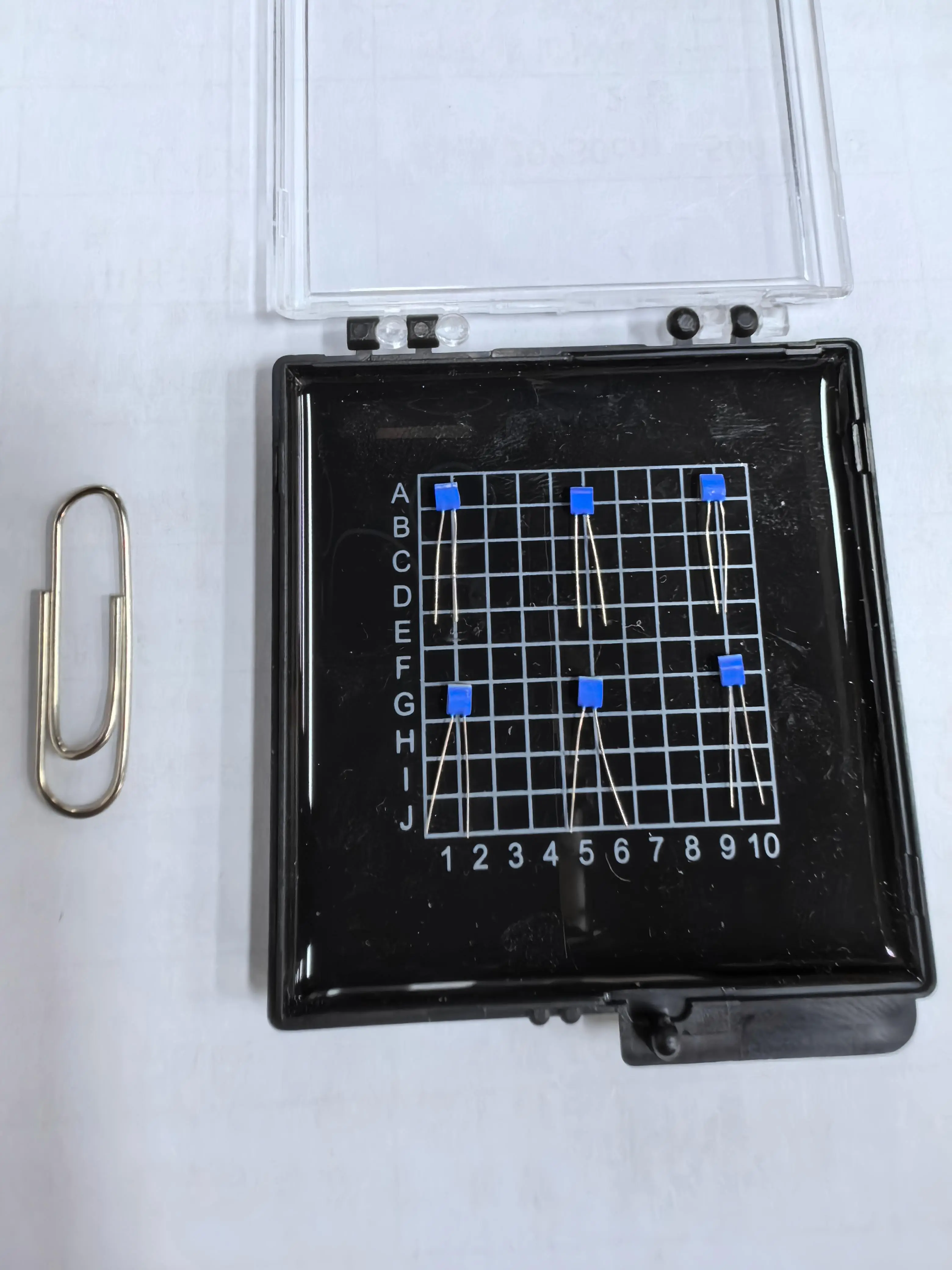

PT1000 platinum thermistor has become a popular choice in industrial temperature measurement, medical equipment, and high-precision instruments due to its excellent stability and sensitivity. However, many engineers feel confused when selecting different types such as PT100, PT500, and PT1000. This article will provide you with a practical guide for PT1000 selection from the perspectives of core parameters, application scenarios, and cost-effectiveness, helping you make the best decisions.

The basic principles and advantages of PT1000

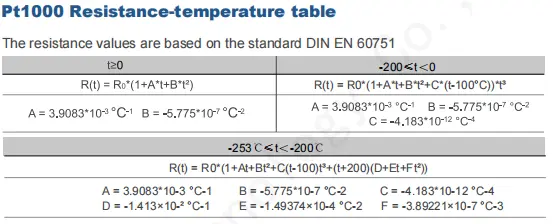

PT1000 is a platinum thermistor sensor with a nominal resistance of 1000 ohms at 0 ℃, and the resistance value increases approximately linearly with temperature (for example, the resistance value is about 1385 ohms at 100 ℃). Compared with PT100 (resistance of 100 ohms at 0 ℃), PT1000 has higher sensitivity, with a resistance change of about 3.8 ohms for every 1 ℃ temperature change, while PT100 only changes by about 0.38 ohms. This high sensitivity enables it to detect small temperature fluctuations, making it particularly suitable for small range high-precision measurement scenarios. In addition, PT1000 usually adopts a two-wire connection, which can ignore the influence of lead resistance due to its high resistance value, reducing the cost of the circuit.

Analysis of key selection parameters

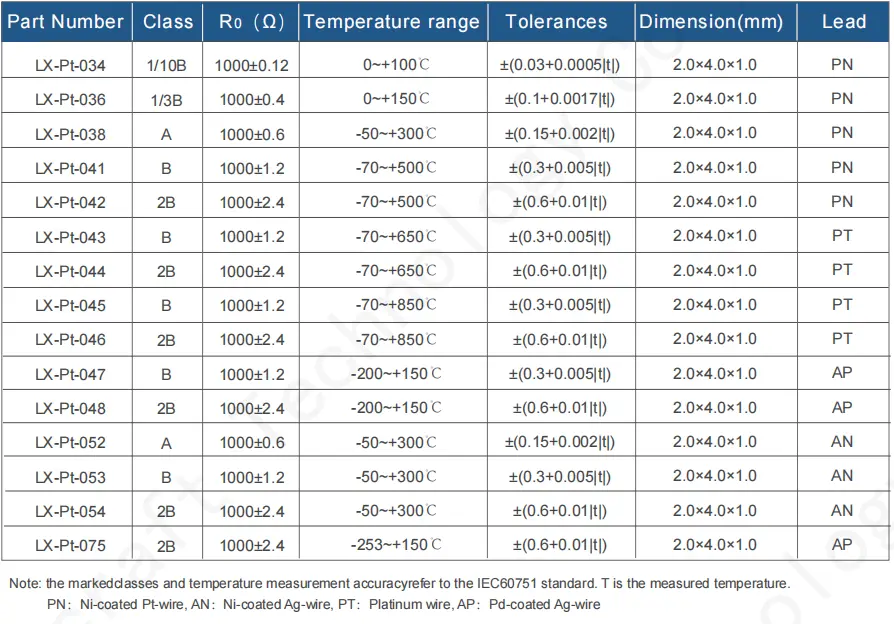

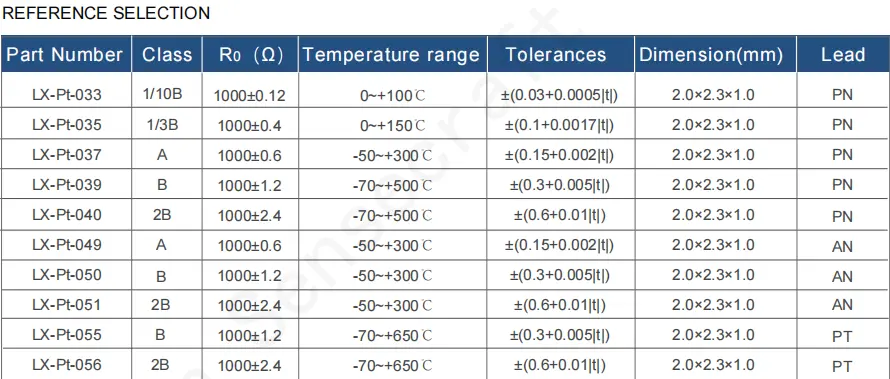

Measurement range and accuracy level: The typical temperature measurement range of PT1000 is -200 ℃ to+800 ℃. When selecting, the accuracy level should be determined based on the actual temperature range (such as Class A and Class B in IEC 60751 standard). For example, the A-level accuracy error is ± (0.15+0.002 | t |) ℃, which is suitable for fields such as medical equipment that require high accuracy; B-level error is slightly larger, but the cost is lower and suitable for general industrial scenarios.

Temperature Coefficient (TCR): The temperature coefficient of PT1000 is typically 3850 ppm/℃ (i.e. 0.003851/℃), which means that the resistance value has a predictable response to temperature changes. When selecting, it should be ensured that the TCR of the components meets the standards (such as IEC 60751) to ensure measurement consistency.

Self heating effect and working current: The working current of PT1000 needs to be controlled within 0.1-0.3 mA. Excessive current can cause self heating effect (such as 0.4 ° C/mW) and introduce measurement errors. In low-power applications such as battery powered devices, PT1000 has an advantage over PT100 due to its lower operating current (≤ 0.3 mA).

Long term stability and packaging form: If the application environment involves high temperature or vibration (such as industrial furnaces), attention should be paid to the long-term stability of the components (such as R0 drift ≤± 0.04% after 1000 hours at 500 ℃). The packaging form (such as ceramic, glass, or stainless steel armor) affects corrosion resistance and mechanical strength, for example, 316L stainless steel packaging is suitable for acid and alkali resistant environments.

Comparison with PT100/PT500: How to choose?

PT1000: Suitable for high sensitivity, two-wire low-cost wiring scenarios, such as medical equipment, consumer electronics, or remote sensor installation.

PT100: Although it has lower sensitivity, it has stronger stability and anti-interference ability, and is widely used in industrial process control (often using a three wire or four wire system to eliminate line resistance errors).

PT500: The resistance value is between the two, which is a compromise between cost and performance, suitable for applications with certain sensitivity requirements but limited budget.

Common problems in selection practice

Lead selection: Two wire system is suitable for PT1000 (due to minimal impact of wire resistance); The three wire or four wire system is more suitable for PT100 to compensate for the resistance caused by long leads.

Response time considerations: If rapid temperature measurement is required (such as fluid monitoring), models with shorter thermal response times should be selected, such as the water flow response time t ₀ of the membrane PT1000 ₅ can reach 0.05 seconds.

Environmental adaptability: In environments with strong vibration or impact (such as aerospace), it is necessary to ensure that the component has a vibration resistance of ≥ 40g and an impact resistance of ≥ 100g.

summary

When choosing PT1000, it is necessary to comprehensively evaluate the measurement range, accuracy requirements, wiring costs, and environmental conditions. For high-precision and small-scale temperature measurement, PT1000 is an ideal choice due to its high sensitivity; For harsh industrial environments, PT100 may be more reliable. It is recommended to refer to the grading table and technical parameters provided by the manufacturer before selection.

Author Introduction: This article is written by a temperature sensor expert, based on the IEC 60751 standard and years of engineering application experience, aiming to help users optimize the selection process.

FAQ

Q1: Can PT1000 directly replace PT100?

Not fully compatible. Due to different resistance values, it is necessary to adjust the program or calibration parameters of the backend circuit, otherwise it may cause measurement errors.

Q2: What is the lifespan of PT1000 under high temperature conditions?

If the selection is correct (such as using ceramic packaging), it can work stably for a long time at 500 ℃ and have a lifespan of several years.

Q3: How to ensure the measurement accuracy of the two-wire PT1000?

By using a high-precision constant current source and controlling the working current to be ≤ 0.3 mA, the influence of self heating effect can be effectively reduced.

Understanding the relationship between thermistor resistance and temperature response requires a comprehensive analysis of the basic resistance temperature relationship, dynamic response characteristics, and advanced measurement techniques. Professional thermistor applications benefit from the systematic analysis of temperature coefficient, optimization of response time, and implementation of precise measurement. Advanced technology has enhanced signal characteristics and environmental stability, providing excellent performance while simplifying system integration and maintenance requirements to meet demanding temperature measurement applications.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, specializing in high-performance temperature sensors for demanding industrial applications. We have comprehensive expertise in microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods to ensure the excellent performance and reliability of thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including core sensitive chips, testing systems, and analysis software. Please contact our technical experts sales11@xatzd.com Discuss your specific thermistor requirements and learn how our advanced resistor temperature optimization and manufacturing capabilities can enhance the performance and reliability of your temperature measurement system

Learn about our latest products and discounts through SMS or email