- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Installation and Maintenance Guide for PT1000 Platinum Thermistor: Avoiding Common Errors

Installation and Maintenance Guide for PT1000 Platinum Thermistor: Avoiding Common Errors

Proper installation and maintenance are key to ensuring the long-term stable operation of PT1000 platinum thermistor. Many on-site malfunctions, such as measurement drift or component damage, are not caused by the sensor itself, but rather by improper installation or maintenance negligence. This article will provide a detailed explanation of the installation steps, wiring techniques, and maintenance points for PT1000, helping you improve system reliability.

Preparation work before installation

Before installation, it is necessary to confirm that the specifications of PT1000 match the application requirements:

Verify parameters: Check the temperature range (-200 ℃ to+800 ℃), accuracy level (such as Class A ± 0.1 ℃), and packaging material (such as 316L stainless steel corrosion resistance).

Environmental assessment: Avoid installing in locations with strong electromagnetic interference or excessive mechanical vibration, and add heat shields or cushioning pads if necessary.

Tool preparation: including torque wrench (to prevent damage from over tightening), insulation tester (to verify insulation resistance ≥ 100 M Ω).

Correct installation steps and wiring specifications

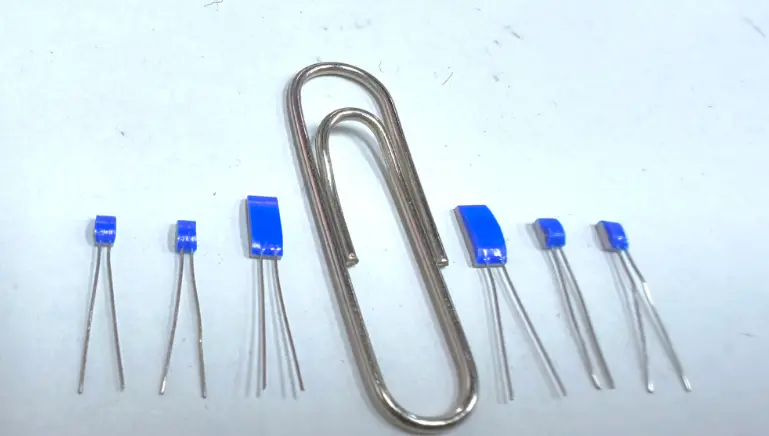

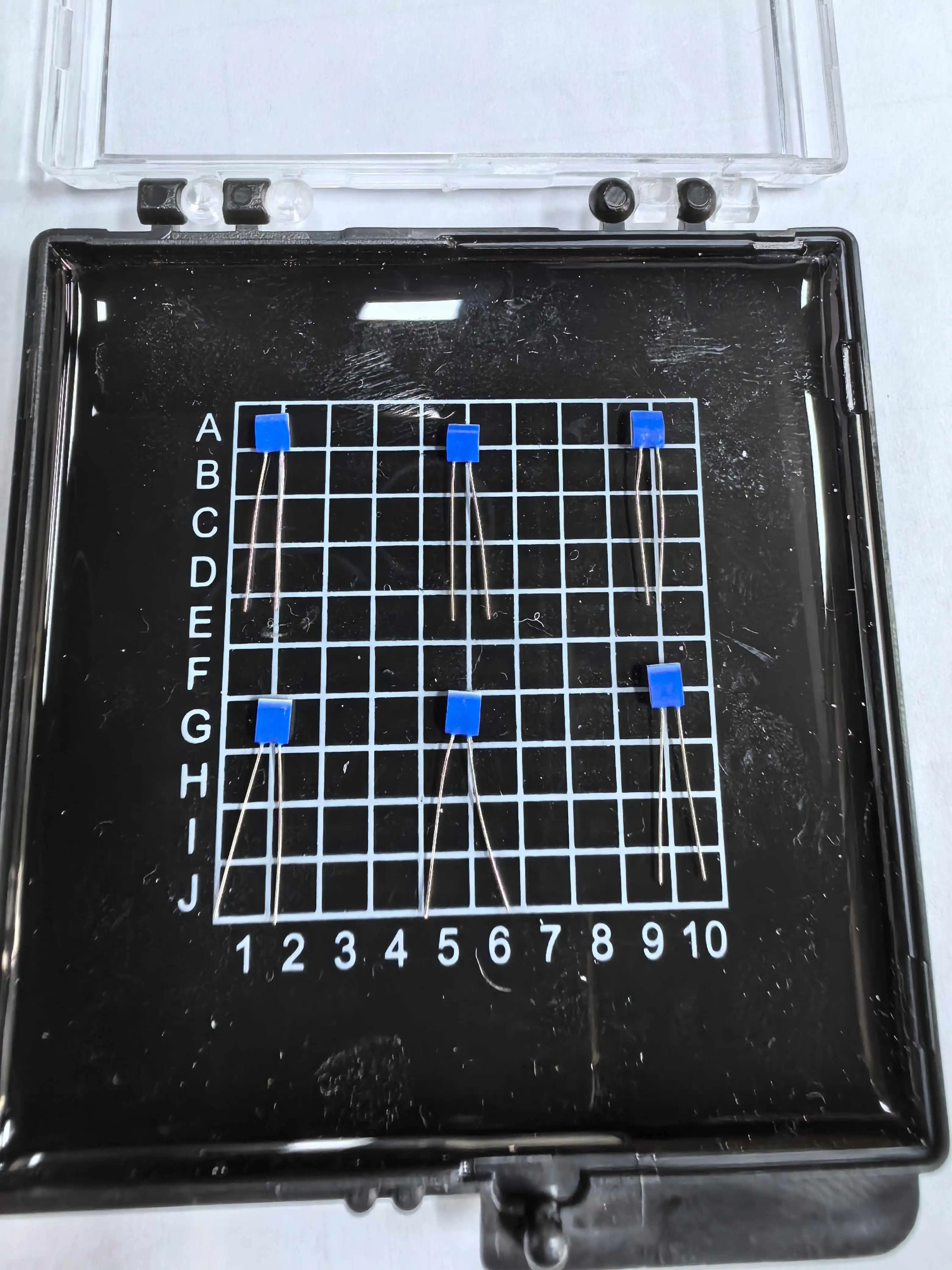

Lead connection: PT1000 supports two-wire, three wire, or four wire systems. The two-wire system is most commonly used due to its low impact on lead resistance; If the distance is far (such as>10 meters), it is recommended to use a three wire system to compensate for line resistance. The lead material (such as platinum nickel wire) should be resistant to high temperatures, and silver palladium solder should be used at the welding points to avoid oxidation.

Mechanical installation: For threaded or flange installation (such as step probes), it is necessary to ensure that the probe is in full contact with the measured medium, but avoid excessive tightening (torque ≤ 5 N · m) to prevent deformation of the housing. For example, during pipeline installation, the probe should be inserted in reverse flow to reduce flow impact.

Optimization of thermal response time: To shorten response time (such as t ₀ in water flow) ₅=0.05 seconds), it should be ensured that the probe is directly exposed to the medium, not an air gap. For airflow measurement, the response speed can be improved by increasing the flow velocity (e.g. ≥ 2 m/s).

Daily maintenance and troubleshooting

Regular calibration: It is recommended to verify the R0 value (0 ℃ resistance) every 6 months, and recalibrate if the drift exceeds ± 0.04%.

Cleaning and insulation inspection: Carbon buildup or dirt can cause poor thermal conductivity, and can be cleaned with anhydrous ethanol; Insulation resistance below 2 M Ω (at 500 ℃) indicates aging of the package and replacement is required.

Common troubleshooting:

Reading jump: Check for short circuit or poor contact of the leads, with a focus on investigating the entry of the junction box.

Slow response: may be due to probe scaling, cleaning or replacement of protective tube.

Out of tolerance alarm: Verify if the working current is ≤ 0.3 mA to avoid self heating effects.

summary

Standardized installation and maintenance can significantly extend the lifespan of PT1000. The core lies in fine wiring, mechanical stress control, and regular calibration. For high-risk scenarios such as chemical reactors, it is recommended to adopt redundant design to enhance safety.

Author Introduction: This article is written by an automation instrumentation engineer, based on a summary of on-site fault cases, aiming to help users reduce system downtime.

FAQ

Q1: How to solve the unstable reading of PT1000 after installation?

Firstly, check if the lead connections are secure, then measure the insulation resistance (which should be ≥ 100 M Ω) and ensure that the operating current does not exceed the limit.

Q2: Can I replace the leads of PT1000 by myself?

Not recommended. Non professional welding may alter TCR characteristics and requires the manufacturer to use specialized equipment for processing.

Q3: What should be paid attention to when installing in high-pressure environments?

Select the armor model (such as IP67 protection) and strengthen the waterproof performance of the lead interface with sealant

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, dedicated to providing high-performance temperature sensors for demanding industrial applications. We have comprehensive expertise in microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods to ensure excellent performance and reliability of thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including core sensitive chips, testing systems, and analysis software. Please contact our technical experts sales11@xatzd.com Discuss your specific thermistor requirements and learn how our advanced resistor temperature optimization and manufacturing capabilities can improve the performance and reliability of your temperature measurement system

Learn about our latest products and discounts through SMS or email