- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

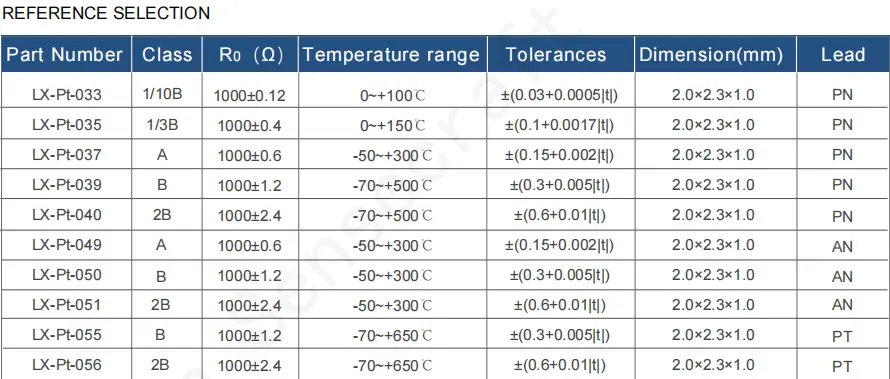

How to choose PT1000 platinum thermistor? Five key factors determine measurement accuracy

How to choose PT1000 platinum thermistor? Five key factors determine measurement accuracy

In the fields of industrial temperature measurement, medical equipment, and new energy, PT1000 platinum thermistor is highly favored for its high precision and stability. However, when faced with different models (such as PT100, PT500, PT1000), many engineers tend to overlook key parameters when selecting, resulting in measurement errors or cost waste. This article combines the selection of core parameters and practical application scenarios to help you quickly identify the most suitable PT1000 solution and improve system reliability.

1. Clarify the temperature measurement range and accuracy level: the first step in basic selection

The temperature measurement range of PT1000 is usually -200 ℃ to+500 ℃ (some models can reach 800 ℃), but different accuracy levels directly affect the error value. For example:

A-level accuracy: The error is ± (0.15+0.002 | T |) ℃, suitable for high-precision scenarios such as medical equipment.

B-level accuracy: slightly larger error, but lower cost, suitable for general industrial process control.

When selecting, it is necessary to balance accuracy and budget according to actual needs. If the measured temperature is often between 0 ℃ and 300 ℃, Class A accuracy can control the error within 0.35 ℃ (taking 100 ℃ as an example), while Class B may reach ± 0.3 ℃ to ± 0.6 ℃.

2. Temperature coefficient (TCR) and self heating effect: hidden key to high precision

The temperature coefficient (TCR) of PT1000 is usually 3850 ppm/℃ (i.e. 0.003851/℃), which means that the resistance value is sensitive to temperature changes and has high linearity. However, the self heating effect is often overlooked:

The working current should be controlled within 0.1-0.3 mA. If the current is too high (such as>1 mA), the self heating effect (0.4 ° C/mW) may cause additional temperature rise.

In low-power applications such as battery powered devices, PT1000 has a much lower self heating effect than PT100 due to its high resistance and low current.

3. Lead selection: 2-wire system vs 3-wire/4-wire system

Two wire system: PT1000 has a high resistance value (1000 Ω at 0 ℃), and the influence of lead resistance can be ignored, making it suitable for long-distance wiring and low cost.

Three wire/four wire system: suitable for PT100 (eliminating line resistance errors), but using multi wire system for PT1000 will increase complexity.

Selection suggestion: For wiring within 10 meters, the two-wire PT1000 is more economical; If there is strong electromagnetic interference in the environment, a three wire system can be used to enhance anti-interference performance.

4. Response time and environmental adaptability: survival rules in harsh scenarios

The response time of PT1000 directly affects the dynamic temperature measurement effect:

In water flow (0.4 m/s): t ₀ ₅ (reaching 50% temperature) only takes 0.05 seconds, suitable for rapid fluid monitoring.

In the airflow (2 m/s): t ₀ About 3 seconds, combined with heat dissipation design.

In vibration or high temperature scenarios (such as industrial furnaces), attention should be paid to vibration resistance (≥ 40g) and insulation resistance (>2 M Ω at 500 ℃). For example, stainless steel armor PT1000 is corrosion-resistant and has high mechanical strength.

5. Long term stability and cost balance: avoid frequent replacement

After running at 500 ℃ for 1000 hours, the R ₀ drift of PT1000 needs to be ≤± 0.04%. If the application involves long-term high temperature (such as energy systems), ceramic based packaging should be preferred to avoid drift caused by platinum layer oxidation. Although the unit price of PT1000 may be higher than PT100, its high sensitivity can reduce circuit compensation costs and overall cost-effectiveness is better.

Summary: PT1000 Selection Checklist

Prioritize PT1000 scenarios: high sensitivity requirements, two-wire wiring, low-power devices (such as medical instruments, new energy vehicle battery packs).

Choose PT100 for better scenarios: harsh industrial environments (requiring three wire/four wire compensation), limited budget, and low sensitivity requirements.

Suggest referring to the calibration table provided by the manufacturer (such as IEC 60751) to verify the parameter matching degree

Xi'an Tongzeda Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, dedicated to providing high-performance temperature sensors for demanding industrial applications. We have comprehensive expertise in microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods to ensure excellent performance and reliability of thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including core sensitive chips, testing systems, and analysis software. Please contact our technical experts sales11@xatzd.com Discuss your specific thermistor requirements and learn how our advanced resistor temperature optimization and manufacturing capabilities can improve the performance and reliability of your temperature measurement system

Learn about our latest products and discounts through SMS or email