- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Performance Analysis and Application Case of PT1000 Platinum Thermistor in High Temperature Environment

Performance Analysis and Application Case of PT1000 Platinum Thermistor in High Temperature Environment

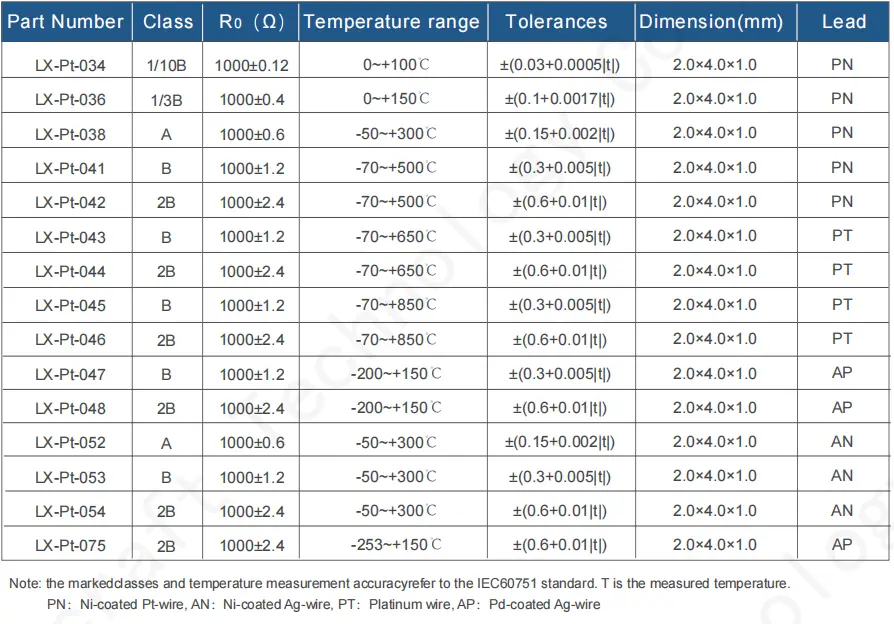

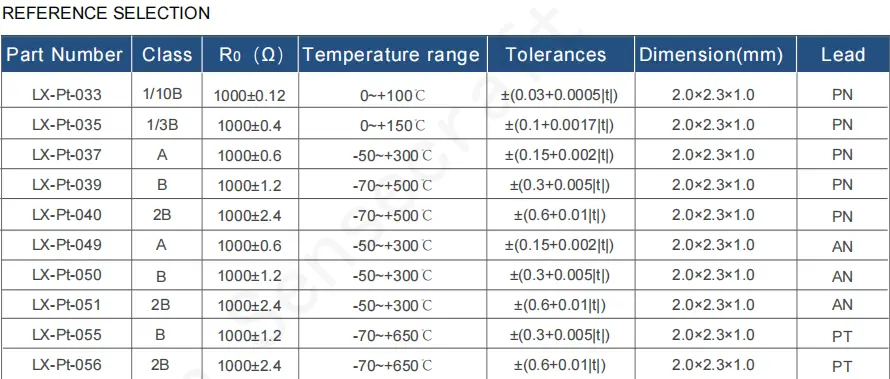

High temperature environments, such as industrial furnaces and energy systems, place extreme demands on the stability, corrosion resistance, and vibration resistance of temperature sensors. The PT1000 platinum thermistor performs excellently in these scenarios due to its high sensitivity and robust performance. This article combines specific cases to analyze the performance parameters of PT1000 at high temperatures and share best practices.

High temperature performance characteristics of PT1000

In the high temperature range (such as 500 ℃), the core advantages of PT1000 are reflected in:

Long term stability: After running at 500 ℃ for 1000 hours, the resistance drift of R0 can be controlled within ± 0.04%, ensuring measurement consistency.

Insulation resistance guarantee: The insulation resistance is ≥ 100 M Ω at 20 ℃, and can still maintain>2 M Ω even at high temperatures of 500 ℃, effectively preventing leakage errors.

Mechanical durability: Vibration resistance ≥ 40g, impact resistance ≥ 100g, suitable for high-frequency vibration scenarios such as fluidized bed boilers.

Analysis of High Temperature Application Cases

Steel and metallurgical furnaces:

Challenge: Large temperature fluctuations (300 ℃~800 ℃), strong corrosiveness of dust.

Solution: Adopt a step probe PT1000316L stainless steel armored protective tube (temperature resistant to 800 ℃), combined with three wire wiring to reduce signal interference. Install wear-resistant coating during installation, which increases the service life to more than 2 years.

Medical sterilization equipment:

Challenge: Need for quick response (t ₀) <10 seconds) and high accuracy (± 0.1 ℃).

Solution: The thin film PT1000 (size 2.0mm × 2.3mm) directly contacts the medium and utilizes its low heat capacity to achieve rapid temperature measurement. The working current is set to 0.1 mA, and the self heating effect can be ignored.

New energy vehicle battery pack:

Challenge: Narrow space and presence of electromagnetic interference.

Solution: Micro PT1000 (such as 2.0mm × 4.0mm package) is mounted on the surface of the battery cell, and the two-wire wiring simplifies the architecture. Its high sensitivity (3.8 Ω/℃) can provide early warning of overheating risks.

Technical points for optimizing high-temperature performance

Packaging selection: For environments above 500 ℃, ceramic based or high-temperature alloy packaging (such as titanium alloy) is preferred to avoid platinum layer oxidation.

Thermal compensation strategy: Correct nonlinear errors through software algorithms (such as table lookup), especially in the range outside 0 ℃~300 ℃.

Heat dissipation design: Install heat sinks in enclosed spaces or wrap leads into coils to dissipate heat and prevent local overheating.

summary

PT1000 combines high precision and robustness in high-temperature applications. The key to success lies in targeted packaging design, standardized installation processes, and regular maintenance. For extreme environments (such as>800 ℃), it is recommended to use thermocouples in combination.

Author Introduction: This article is written by a thermal engineering expert, based on industry application data, aiming to help users explore the potential of PT1000 in high-temperature scenarios.

FAQ

Q1: Can PT1000 be used above 800 ℃?

Not recommended. Platinum element may evaporate at high temperatures, causing resistance drift, and the upper limit should be controlled within 800 ℃.

Q2: How to protect the leads under high temperature?

Use silver plated platinum nickel wire (resistant to oxidation) and cover it with a glass fiber sleeve. The lead length should be as short as possible to reduce heat conduction.

Q3: How to verify high temperature performance?

Gradually increase the temperature in the constant temperature chamber, compare the readings of the standard thermocouple, and draw an error curve

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, dedicated to providing high-performance temperature sensors for demanding industrial applications. We have comprehensive expertise in microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods to ensure excellent performance and reliability of thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including core sensitive chips, testing systems, and analysis software. Please contact our technical experts sales11@xatzd.com Discuss your specific thermistor requirements and learn how our advanced resistor temperature optimization and manufacturing capabilities can improve the performance and reliability of your temperature measurement system

Learn about our latest products and discounts through SMS or email