Understanding High-Stability Pt1000 Sensor Characteristics

High-Stability Pt1000 Sensors are platinum resistance thermometers (PRTs) that offer exceptional accuracy and long-term stability for temperature measurements. These sensors are widely used in various industries due to their reliability and precision. To effectively design thermal systems using these sensors, it's crucial to understand their key characteristics.

Temperature Coefficient and Resistance

The temperature coefficient of resistance (TCR) is a fundamental property of Pt1000 sensors. High-quality sensors typically have a TCR of 3850 ppm/°C, which complies with the IEC60751 standard. This coefficient indicates how the sensor's resistance changes with temperature, allowing for accurate temperature calculations.

Pt1000 sensors have a nominal resistance of 1000 ohms at 0°C, which increases linearly with temperature. This linear relationship simplifies temperature calculations and improves measurement accuracy across a wide range.

Long-Term Stability and Accuracy

One of the most critical aspects of High-Stability Pt1000 Sensors is their exceptional long-term stability. Premium sensors exhibit a resistance drift of ≤±0.04% of R₀ (0°C reference) after 1000 hours at 500°C. This remarkable stability ensures reliable measurements over extended periods, making these sensors ideal for applications requiring long-term monitoring.

The accuracy of Pt1000 sensors can reach ±0.01 Ω, translating to temperature measurements with precision down to fractions of a degree. This high level of accuracy is essential for applications in industries such as aerospace, medical equipment, and industrial process control.

Operating Range and Environmental Resistance

High-Stability Pt1000 Sensors offer an impressive operating temperature range, typically spanning from -200°C to +850°C. This wide range makes them suitable for diverse applications, from cryogenic systems to high-temperature industrial processes.

These sensors also demonstrate excellent resistance to environmental factors. With vibration resistance of ≥40g acceleration (in the frequency range of 10-2000 Hz) and shock resistance of ≥100g acceleration (8 ms half-sine wave), they can withstand harsh industrial environments and maintain accuracy under challenging conditions.

Designing Thermal Systems with Pt1000 Sensors

When incorporating High-Stability Pt1000 Sensors into thermal system designs, several factors must be considered to ensure optimal performance and accuracy.

Sensor Selection and Placement

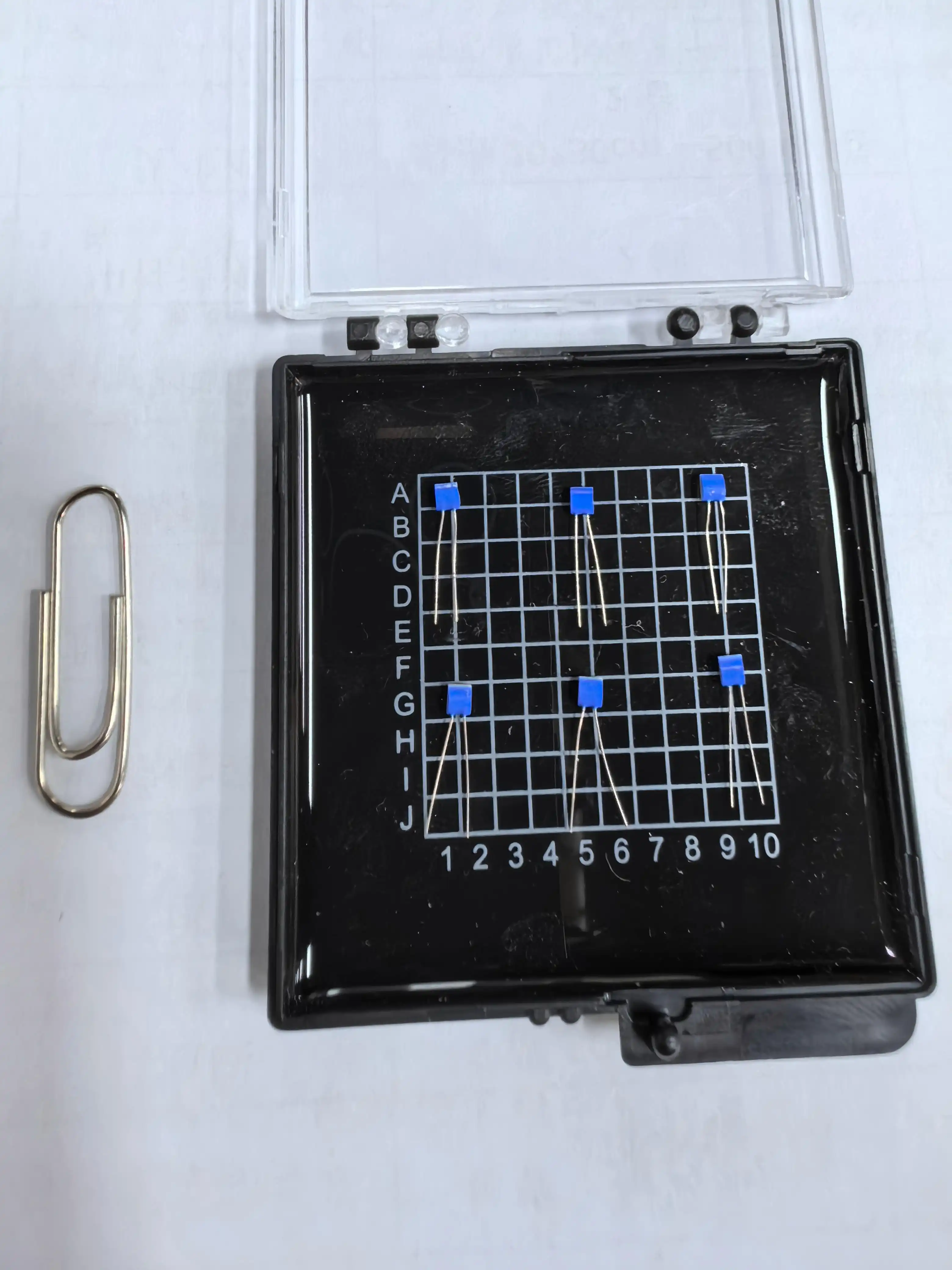

Choosing the right Pt1000 sensor for your application is crucial. Consider factors such as the required temperature range, accuracy, and response time. For instance, sensors with dimensions of 2.0mm x 2.3mm x 1.0mm or 2.0mm x 4.0mm x 1.0mm offer compact sizes suitable for various applications.

Proper sensor placement is essential for accurate temperature measurements. Position the sensor in a location that best represents the system's temperature, avoiding areas with rapid fluctuations or heat sinks. Consider using thermal compounds or specialized mounting techniques to ensure good thermal contact between the sensor and the measured surface.

Signal Conditioning and Data Acquisition

Pt1000 sensors require precise signal conditioning to convert resistance changes into accurate temperature readings. Implement a high-quality, low-noise measurement circuit to maximize the sensor's performance. Consider using a four-wire connection method to eliminate lead resistance effects, especially for long cable runs.

Choose an appropriate data acquisition system with sufficient resolution and sampling rate to capture temperature changes accurately. For applications requiring rapid response, consider the sensor's response time characteristics. In water flow (V=0.4 m/s), t₀.₅ is 0.05 s and t₀.₉ is 0.15 s, while in airflow (V=2 m/s), t₀.₅ is 3 s and t₀.₉ is 10 s.

Calibration and Compensation

To achieve the highest accuracy, calibrate the Pt1000 sensor and measurement system using certified reference standards. Develop a calibration curve that accounts for any slight non-linearities in the sensor's response.

Implement compensation algorithms to address factors such as self-heating and lead wire resistance. The self-heating coefficient of 0.4°C/mW (at 0°C) should be considered when determining the appropriate operating current, typically in the range of 0.1-0.3 mA.

Advanced Considerations for High-Performance Thermal Systems

To maximize the potential of High-Stability Pt1000 Sensors in thermal system designs, consider these advanced techniques and considerations.

Multi-Sensor Arrays and Redundancy

For critical applications or large-scale thermal systems, implement multi-sensor arrays using multiple Pt1000 sensors. This approach allows for temperature mapping across the system and provides redundancy in case of sensor failure. Design your data acquisition system to handle multiple sensor inputs and develop algorithms to analyze and correlate data from multiple sensors.

Environmental Protection and Packaging

Protect the Pt1000 sensors from harsh environmental conditions to ensure long-term stability and accuracy. Consider using specialized packaging options, such as vacuum plastic packaging, to shield the sensors from moisture, chemicals, or mechanical stress. For extreme environments, explore custom packaging solutions that maintain the sensor's performance while providing adequate protection.

Integration with Control Systems

When designing thermal systems for process control applications, integrate the Pt1000 sensors seamlessly with your control system. Develop control algorithms that take advantage of the sensor's high stability and accuracy to achieve precise temperature regulation. Implement appropriate safety measures and alarm systems based on the sensor readings to ensure safe operation of the thermal system.

Consider implementing predictive maintenance strategies using the long-term stability data from the Pt1000 sensors. By monitoring sensor drift over time, you can schedule maintenance or sensor replacement before accuracy is compromised.

Customization and Special Applications

For unique or demanding applications, explore customization options for Pt1000 sensors. Manufacturers like Xi'an Tongzida Technology Co., Ltd. offer customized options for sensor sizes (ranging from 1.2mm to 4.0mm) and lead materials (including platinum-nickel, silver-palladium, platinum, or pure silver wires). These customizations can help optimize the sensor's performance for specific thermal system requirements.

In high-precision applications, consider using sensors with higher accuracy classes or implementing multi-point calibration techniques to further enhance measurement accuracy across the entire temperature range.

Conclusion

Designing thermal systems using High-Stability Pt1000 Sensors requires a comprehensive understanding of sensor characteristics, careful system integration, and attention to environmental factors. By leveraging the exceptional stability, accuracy, and wide operating range of these sensors, engineers can create highly reliable and precise thermal systems for various applications.

As technology continues to advance, the integration of High-Stability Pt1000 Sensors with emerging technologies such as IoT and AI-driven analytics presents exciting opportunities for even more sophisticated thermal system designs. By staying informed about the latest developments in sensor technology and measurement techniques, designers can continue to push the boundaries of thermal system performance and reliability.

For more information on High-Stability Pt1000 Sensors and their applications in thermal system design, please contact our team of experts at sales11@xatzd.com. Our specialists are ready to assist you in selecting the ideal sensors for your specific requirements and provide guidance on optimizing your thermal system design.