The Technological Marvels of Thin Film Pt100 Sensors

Precision Engineering at the Microscale

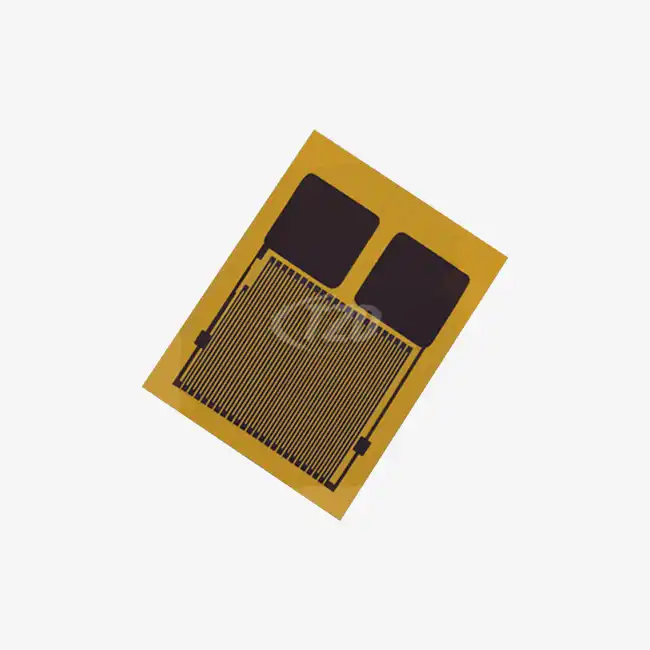

Thin Film Pt100 sensors represent a pinnacle of precision engineering. These sensors are fabricated using advanced thin-film deposition techniques, where a microscopic layer of platinum is meticulously applied to a ceramic substrate. This process results in a sensor element with exceptional uniformity and stability. The platinum layer, typically mere nanometers thick, is etched into a precise pattern that maximizes sensitivity while minimizing size.

The manufacturing process of these sensors involves state-of-the-art clean room facilities and automated production lines. This level of precision ensures that each sensor meets the stringent IEC60751 standard, guaranteeing a temperature coefficient of 3850 ppm/°C. This high coefficient translates to superior sensitivity, allowing the sensors to detect minute temperature changes with remarkable accuracy.

Unmatched Temperature Range and Stability

One of the most impressive features of Thin Film Pt100 sensors is their vast operational temperature range. These sensors can accurately measure temperatures from a frigid -200°C to a scorching +850°C. This expansive range makes them ideal for aerospace applications, where equipment may be exposed to the extreme cold of high altitudes or the intense heat generated by engines and re-entry.

Moreover, these sensors boast exceptional long-term stability. With a drift of ≤0.04% over extended periods, they provide reliable measurements even after thousands of hours of operation in harsh conditions. This stability is crucial in aerospace applications, where sensor recalibration can be challenging or impossible once a craft is in operation.

Miniaturization Without Compromise

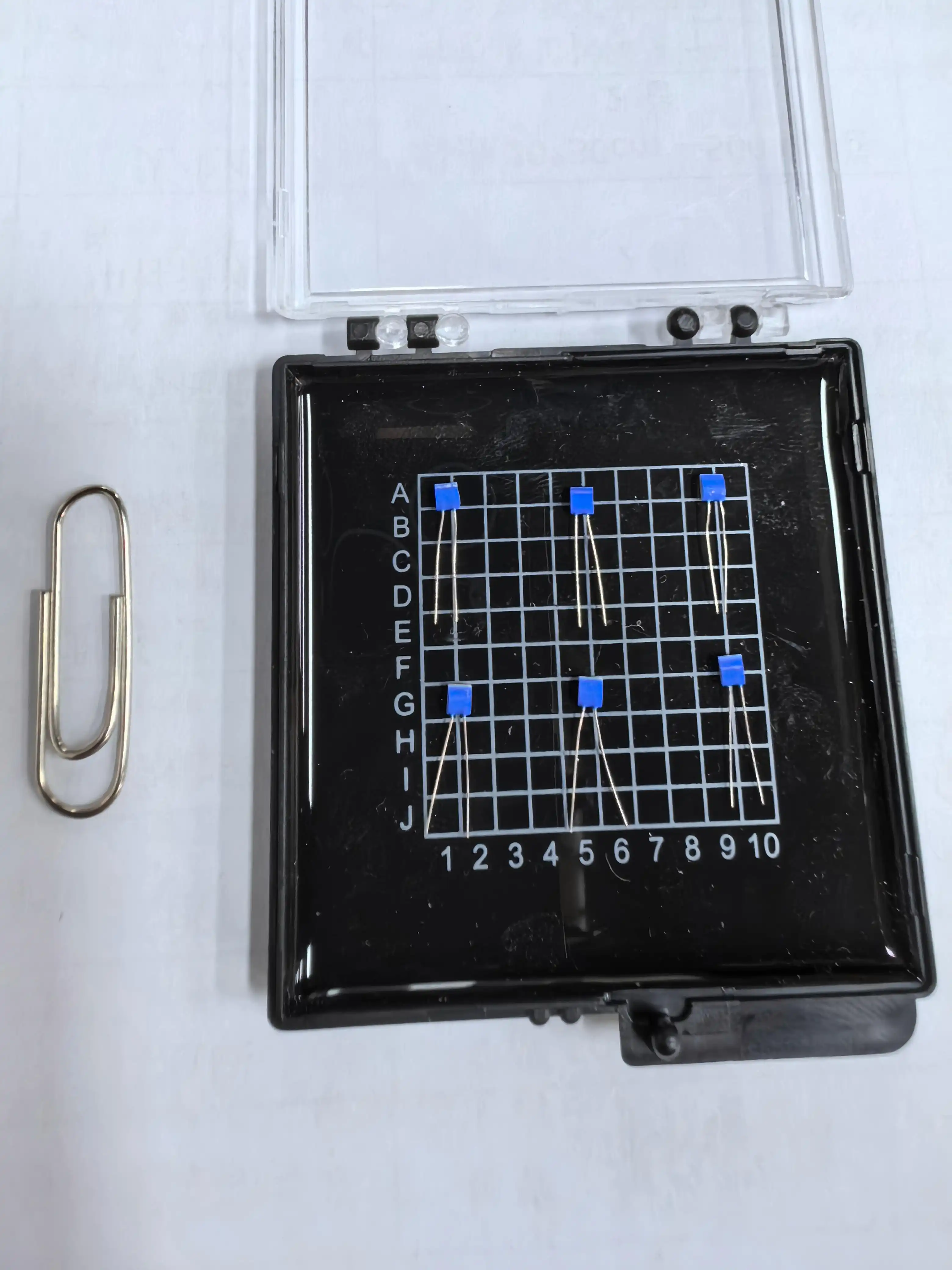

The compact nature of Thin Film Pt100 sensors is a game-changer in aerospace design. With dimensions as small as 3.2mm x 1.6mm x 0.7mm, these sensors can be integrated into the most space-constrained areas of aircraft and spacecraft. This miniaturization is achieved without sacrificing performance, thanks to the precision of thin-film technology.

Despite their small size, these sensors maintain impressive durability. They can withstand vibrations of up to 40g and impacts of 100g, making them resilient to the rigors of takeoff, turbulence, and landing. The ability to pack such high performance into a tiny package is invaluable in aerospace applications, where every gram of weight and every millimeter of space counts.

Aerospace-Specific Advantages of Thin Film Pt100 Sensors

Rapid Response in Critical Situations

In aerospace applications, the speed of temperature measurement can be a matter of safety and efficiency. Thin Film Pt100 sensors excel in this aspect, offering response times as quick as 0.05 seconds. This rapid response is crucial for real-time monitoring of engine temperatures, environmental control systems, and other critical components where sudden temperature changes could indicate potential issues.

The quick response is attributed to the sensor's thin-film construction. The minimal thermal mass of the platinum layer allows it to reach thermal equilibrium with its surroundings almost instantaneously. This characteristic enables aerospace systems to react swiftly to temperature changes, enhancing overall safety and performance.

Resistance to Electromagnetic Interference

Aerospace environments are rife with electromagnetic fields from various electronic systems and communication equipment. Thin Film Pt100 sensors demonstrate excellent resistance to electromagnetic interference (EMI), ensuring accurate temperature readings even in these electronically noisy environments.

The EMI resistance is partly due to the sensors' construction. The thin platinum film and the ceramic substrate create a naturally low-inductance device. Additionally, advanced shielding techniques can be applied during the sensor's packaging process, further enhancing its immunity to electromagnetic disturbances.

Customization for Specific Aerospace Needs

The aerospace industry often requires sensors tailored to specific applications. Thin Film Pt100 sensors offer a high degree of customization. Manufacturers can produce these sensors in various sizes, ranging from 1.2mm to 4.0mm, to fit diverse installation requirements. Furthermore, the choice of lead materials, including platinum-nickel alloys, silver-nickel alloys, or pure platinum, allows for optimization based on the specific environmental conditions and electrical characteristics of the application.

This flexibility extends to the sensor's packaging and mounting options. Whether it's a need for hermetically sealed sensors for pressurized environments or special mounting configurations for tight spaces, Thin Film Pt100 sensors can be adapted to meet these specialized aerospace requirements.

Future Prospects and Innovations in Thin Film Pt100 Technology

Integration with Advanced Avionics

As avionics systems become more sophisticated, the integration of Thin Film Pt100 sensors is expected to deepen. These sensors are increasingly being incorporated into advanced flight control systems, health monitoring systems, and predictive maintenance algorithms. Their high accuracy and reliability make them ideal for these critical applications, where precise temperature data can inform complex decision-making processes in real-time.

Future developments may see these sensors equipped with built-in signal processing capabilities, allowing for direct digital output and easier integration with digital avionics systems. This could lead to more streamlined temperature monitoring systems with reduced wiring complexity and improved overall system reliability.

Advancements in Materials Science

Ongoing research in materials science promises to push the boundaries of what Thin Film Pt100 sensors can achieve. New substrate materials and platinum alloys are being explored to extend the temperature range even further and improve stability under extreme conditions. These advancements could lead to sensors capable of operating reliably in even more challenging aerospace environments, such as those encountered in hypersonic flight or space exploration.

Additionally, research into nano-structured platinum films could result in sensors with even faster response times and higher sensitivity. These improvements would enable more precise control of aerospace systems and potentially open up new applications in areas like supersonic and hypersonic flight, where rapid temperature changes are more pronounced.

Enhanced Durability for Space Applications

As space exploration continues to advance, Thin Film Pt100 sensors are being developed to withstand the unique challenges of the space environment. This includes resistance to radiation, which can affect the performance of electronic components in space. New shielding techniques and radiation-hardened designs are being incorporated to ensure these sensors can provide reliable temperature measurements on long-duration space missions.

Furthermore, efforts are underway to enhance the sensors' resilience to the extreme temperature cycling experienced in space, where objects can rapidly shift from intense heat in direct sunlight to extreme cold in shadow. These improvements will make Thin Film Pt100 sensors even more valuable in spacecraft thermal management systems and scientific instruments used in space exploration.

Conclusion

Thin Film Pt100 sensors have revolutionized temperature measurement in aerospace applications, offering a perfect blend of accuracy, reliability, and compact design. Their wide temperature range, rapid response, and durability make them indispensable in modern aircraft and spacecraft. As technology continues to advance, these sensors are poised to play an even more crucial role in the future of aerospace, enabling safer, more efficient, and more ambitious ventures into the skies and beyond.

For more information about our advanced Thin Film Pt100 sensors and their applications in aerospace and other industries, please contact us at sales11@xatzd.com. Our team of experts is ready to assist you in finding the perfect temperature sensing solution for your specific needs.