- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Pt500 vs Pt100 RTD Chips: Which Is Better for Your Application?

When it comes to choosing between Pt500 and Pt100 RTD chips for temperature sensing applications, the decision ultimately depends on your specific requirements. Pt500 RTD chips offer higher sensitivity and better resolution, making them ideal for applications that demand precise temperature measurements. On the other hand, Pt100 RTD chips are more widely used, cost-effective, and have a longer track record in various industries. For high-accuracy applications in research, aerospace, or medical fields, Pt500 might be the better choice. However, for general industrial use where cost and availability are crucial factors, Pt100 remains a reliable option.

Introducing RTD Technology and Its Applications

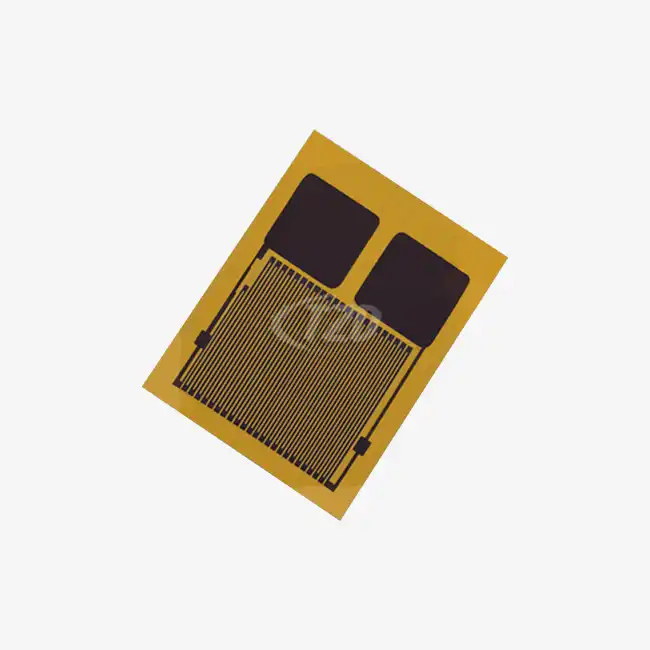

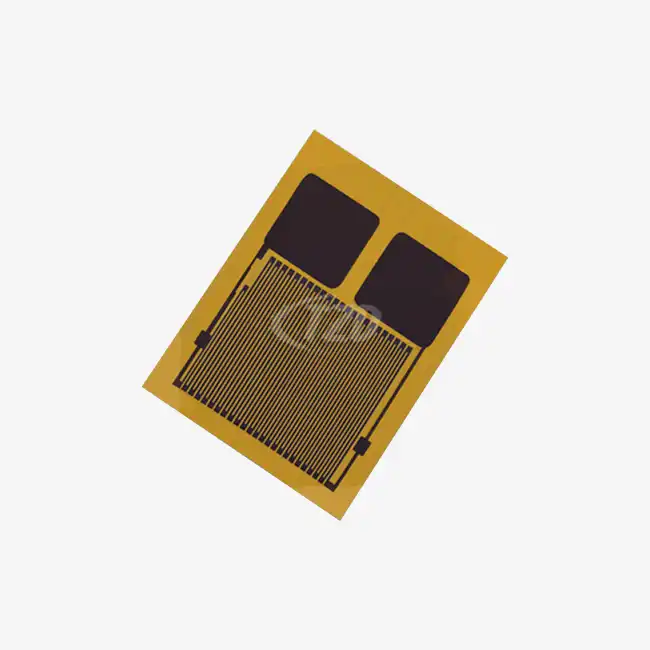

Resistance Temperature Detectors (RTDs) are precision temperature sensors that utilize the principle of electrical resistance change in metals as temperature varies. Among the various types of RTDs, platinum-based sensors, such as the Pt500 RTD chip and Pt100 RTD chip, are renowned for their accuracy, stability, and wide temperature range.

The Fundamentals of RTD Operation

RTDs operate on a simple yet effective principle: as temperature increases, the electrical resistance of the platinum element rises in a predictable and repeatable manner. This relationship between temperature and resistance forms the basis for accurate temperature measurements. The temperature coefficient of resistance (TCR) for platinum RTDs is typically 3850 ppm/°C, as specified by the IEC60751 standard.

Diverse Applications of RTD Technology

RTD sensors find applications across numerous industries due to their reliability and precision. In industrial settings, they monitor processes in chemical plants, refineries, and food processing facilities. The aerospace sector relies on RTDs for engine temperature control and environmental monitoring. Medical equipment, such as incubators and blood analyzers, also benefit from the accuracy of RTD sensors. The automotive industry employs RTDs in engine management systems and climate control units.

Comparing Pt500 and Pt100 RTD Chips

To make an informed decision between Pt500 and Pt100 RTD chips, it's crucial to understand their key differences and how these characteristics impact their performance in various applications.

Resistance Values and Sensitivity

The primary distinction between Pt500 and Pt100 RTD chips lies in their nominal resistance at 0°C. A Pt500 RTD chip has a resistance of 500 ohms at 0°C, while a Pt100 RTD chip has 100 ohms at the same temperature. This higher resistance of the Pt500 RTD chip translates to increased sensitivity, allowing for more precise temperature measurements, especially in applications where small temperature changes are significant.

Accuracy and Stability

Both Pt500 and Pt100 RTD chips offer excellent accuracy and stability. However, the Pt500 RTD chip's higher resistance can provide a slight edge in terms of measurement precision. The long-term stability of these sensors is impressive, with drift typically less than ±0.04% of the resistance at 0°C (R₀) after 1000 hours of operation at 500°C. This stability ensures reliable measurements over extended periods, crucial for many industrial and scientific applications.

Response Time and Self-Heating

The response time of RTD chips is a critical factor in dynamic temperature measurement scenarios. High-quality thin film RTD chips, whether Pt500 or Pt100, can achieve remarkably fast response times. In water flow conditions (V=0.4 m/s), the response time (t₀.₅) can be as low as 0.05 seconds, with 90% of the temperature change (t₀.₉) detected within 0.15 seconds. In air flow (V=2 m/s), the response is slightly slower, with t₀.₅ at 3 seconds and t₀.₉ at 10 seconds.

Self-heating is an important consideration in RTD selection. The self-heating coefficient for these sensors is typically around 0.4°C/mW at 0°C. Pt500 RTD chips, due to their higher resistance, generally experience less self-heating compared to Pt100 chips when the same current is applied, potentially leading to more accurate readings in certain applications.

Selecting the Right RTD Chip for Your Application

Choosing between a Pt500 RTD chip and a Pt100 RTD chip involves careful consideration of various factors specific to your application requirements.

Environmental Considerations

The operating environment plays a crucial role in RTD chip selection. Both Pt500 and Pt100 RTD chips can cover a wide temperature range, typically from -200°C to +850°C. However, the specific design and packaging of the sensor can influence its suitability for extreme conditions. For instance, sensors with high vibration resistance (≥40g acceleration in the 10-2000 Hz range) and shock resistance (≥100g acceleration for 8 ms half-sine wave) are ideal for harsh industrial environments or aerospace applications.

Electrical System Integration

The choice between Pt500 and Pt100 RTD chips can impact the design of your measurement system. Pt500 RTD chips, with their higher resistance, can offer advantages in terms of reduced lead wire effects and improved signal-to-noise ratio, especially in applications with long cable runs. However, Pt100 RTD chips are more commonly used and may be more compatible with existing instrumentation and control systems.

Cost and Availability Factors

While performance is paramount, practical considerations such as cost and availability cannot be overlooked. Pt100 RTD chips are generally more widely available and may be more cost-effective for large-scale applications. Pt500 RTD chips, while offering enhanced sensitivity, might come at a premium and could have longer lead times. The decision should balance the performance requirements of your application with budget and supply chain considerations.

Customization Options

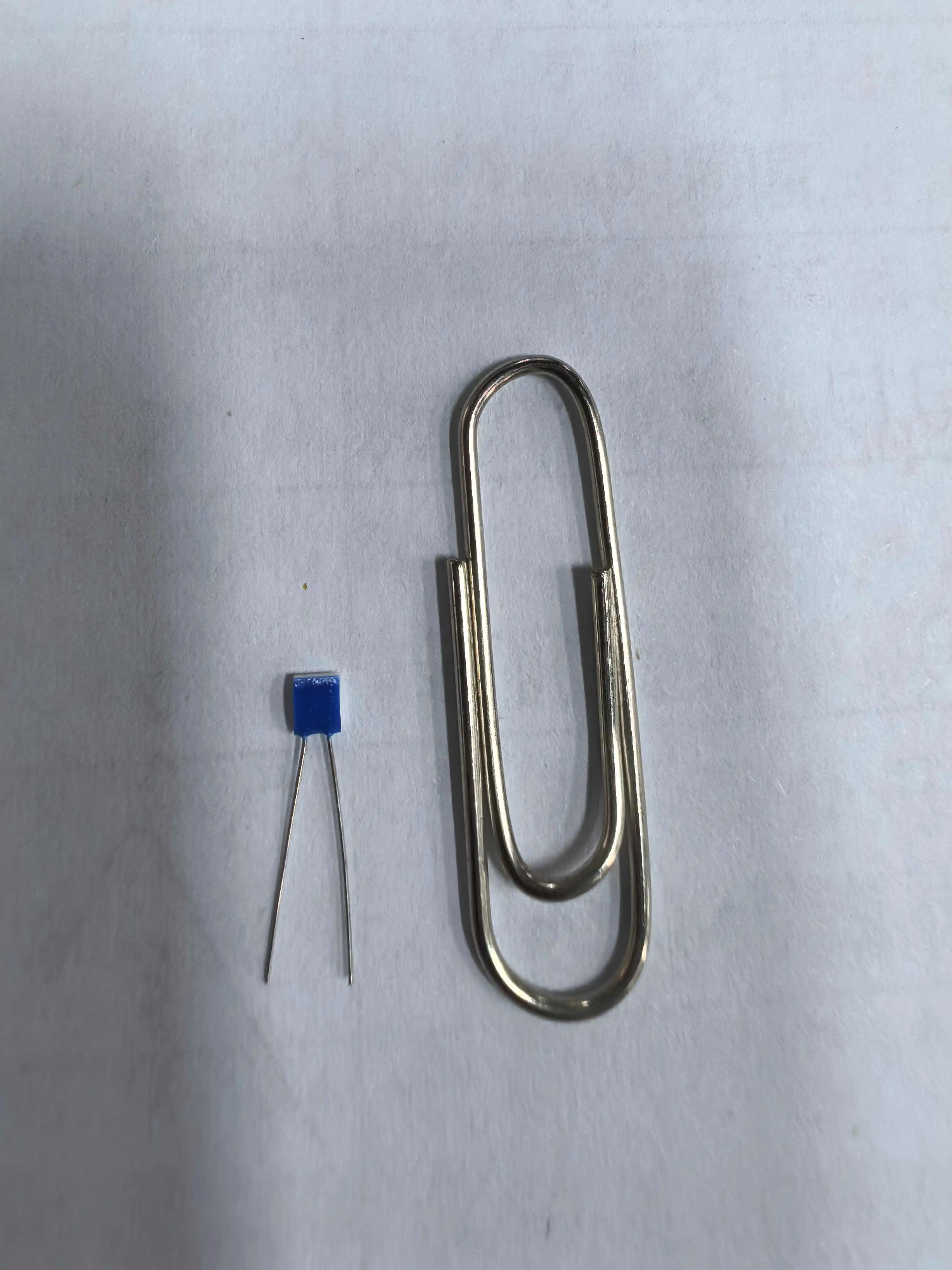

Modern RTD manufacturing techniques allow for significant customization to meet specific application needs. For instance, chip dimensions can be tailored within a range (e.g., 1.2mm to 4.0mm), and various lead materials such as platinum-nickel, silver-palladium, or pure silver can be selected based on the application requirements. This flexibility enables the optimization of the sensor for specific environments and measurement scenarios.

Compliance and Certification

Ensure that the chosen RTD chip complies with relevant industry standards and certifications. High-quality RTD chips should adhere to the IEC60751 standard for industrial platinum resistance thermometers. Additionally, look for manufacturers with ISO9001 quality management system certification and compliance with RoHS and CE directives, especially for applications in regulated industries.

Long-Term Performance and Reliability

Consider the long-term stability and reliability of the RTD chip. Advanced thin film RTD chips can offer excellent long-term stability, with resistance drift of ≤±0.04% after 1000 hours at 500°C. This stability is crucial for applications requiring consistent, accurate measurements over extended periods without frequent recalibration.

Conclusion

The choice between Pt500 and Pt100 RTD chips depends on a careful evaluation of your specific application requirements. While Pt500 RTD chips offer higher sensitivity and potentially better performance in certain scenarios, Pt100 RTD chips remain a versatile and widely adopted option. Consider factors such as measurement precision needs, environmental conditions, system integration, and long-term reliability when making your decision.

For expert guidance on selecting the right RTD chip for your application, feel free to reach out to our team at sales11@xatzd.com. Our specialists can provide personalized recommendations based on your unique requirements, ensuring you choose the optimal solution for your temperature sensing needs.

References

1. Baker, B. C. (2018). Precision temperature sensing with RTD circuits. Analog Devices, Inc.

2. Childs, P. R. N., Greenwood, J. R., & Long, C. A. (2000). Review of temperature measurement. Review of Scientific Instruments, 71(8), 2959-2978.

3. Michalski, L., Eckersdorf, K., Kucharski, J., & McGhee, J. (2001). Temperature measurement (2nd ed.). John Wiley & Sons.

4. Nicholas, J. V., & White, D. R. (2001). Traceable temperatures: An introduction to temperature measurement and calibration (2nd ed.). John Wiley & Sons.

5. Perez, R. (2017). Handbook of temperature measurement (Vol. 2): Resistance and liquid-in-glass thermometry. CRC Press.

Learn about our latest products and discounts through SMS or email