- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Determine If PT100 Temperature Sensor Is Damaged? Common Faults

Determining if a PT100 temperature sensor is damaged involves several key indicators. Common faults include inconsistent readings, sudden spikes or drops in temperature measurements, or complete failure to provide any output. To assess potential damage, start by visually inspecting the sensor for physical signs of wear or damage. Then, use a multimeter to check the resistance at a known temperature – a properly functioning PT100 should have a resistance of 100 ohms at 0°C. If the resistance is significantly off or there's no continuity, the sensor may be faulty. Additionally, compare readings with a calibrated reference thermometer to identify any accuracy issues that could indicate sensor damage.

Understanding PT100 Temperature Sensors: Function and Importance

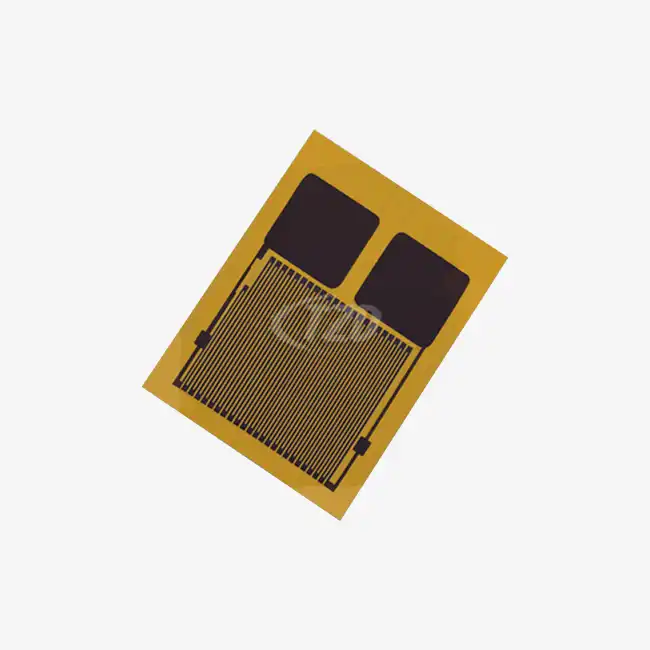

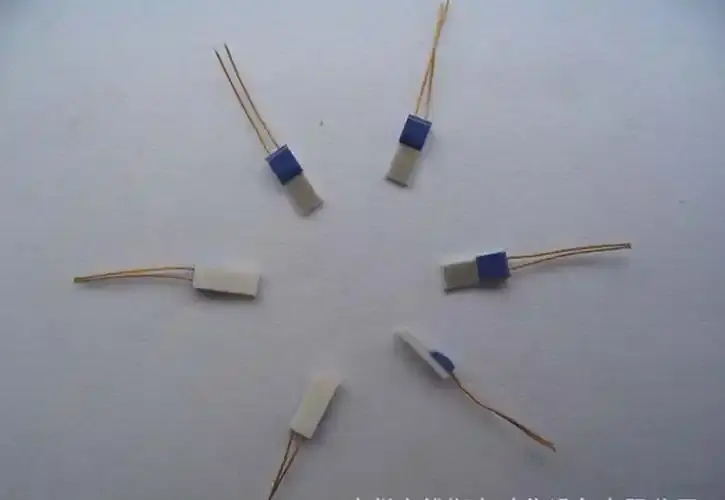

PT100 temperature sensors are precision instruments widely used in various industries for accurate temperature measurement. These sensors, also known as platinum resistance thermometers (PRTs), rely on the principle that electrical resistance in platinum changes predictably with temperature. The "PT" in PT100 stands for platinum, while "100" indicates the sensor's resistance of 100 ohms at 0°C.

The importance of PT100 sensors lies in their exceptional accuracy and stability over a wide temperature range. They are capable of measuring temperatures from -200°C to +850°C with high precision, making them invaluable in applications where temperature control is critical. Industries such as food processing, pharmaceuticals, aerospace, and semiconductor manufacturing heavily rely on these sensors for their operations.

Key Features of PT100 Temperature Sensors

PT100 sensors offer several advantages that contribute to their widespread use:

- High Accuracy: PT100 sensors can achieve accuracies of ±0.01°C or better, depending on the sensor class and calibration.

- Excellent Stability: They maintain their accuracy over long periods, with minimal drift over time.

- Wide Temperature Range: Suitable for both cryogenic and high-temperature applications.

- Linear Response: The resistance change is nearly linear with temperature, simplifying calibration and measurement.

- Interchangeability: Standardized resistance curves allow for easy replacement without recalibration in many cases.

Understanding these features is crucial for recognizing when a PT100 sensor might be compromised or damaged. Any deviation from these expected characteristics could be an indicator of sensor malfunction or damage.

Common Faults in PT100 Temperature Sensors

PT100 temperature sensors, despite their robustness, can experience various faults that affect their performance. Recognizing these common issues is essential for maintaining accurate temperature measurements and ensuring system reliability.

Open Circuit Faults

An open circuit is one of the most frequent faults in PT100 sensors. This occurs when there's a break in the electrical path, often due to physical damage to the sensor or its lead wires. Symptoms include:

- Sudden jumps to maximum or minimum temperature readings

- Infinite resistance when measured with a multimeter

- Complete loss of temperature signal

Short Circuit Faults

Short circuits happen when different parts of the sensor's electrical path come into unintended contact. This can be caused by insulation failure or physical damage. Signs of a short circuit include:

- Abnormally low resistance readings

- Consistently low temperature measurements regardless of actual conditions

- Sudden drops in temperature readings

Insulation Resistance Degradation

Over time, the insulation in PT100 sensors can degrade, especially in harsh environments or at high temperatures. This leads to:

- Gradual drift in temperature readings

- Increased measurement errors at higher temperatures

- Inconsistent readings when the sensor is moved or flexed

Mechanical Stress and Vibration Damage

PT100 sensors exposed to excessive vibration or mechanical stress can suffer internal damage. This may result in:

- Intermittent or erratic readings

- Changes in the sensor's resistance-temperature relationship

- Increased susceptibility to other forms of damage

Contamination and Corrosion

In certain environments, PT100 sensors can be affected by contamination or corrosion, particularly if the protective sheath is compromised. This can lead to:

- Drift in calibration over time

- Reduced sensor lifespan

- Increased measurement errors, especially at temperature extremes

Understanding these common faults is crucial for effective troubleshooting and maintenance of PT100 temperature sensors. Regular inspection and calibration can help detect these issues early, ensuring the continued accuracy and reliability of temperature measurements in critical applications.

Diagnostic Techniques for PT100 Sensor Health Assessment

Assessing the health of PT100 temperature sensors is crucial for maintaining accurate temperature measurements in various industrial and scientific applications. Several diagnostic techniques can be employed to determine if a PT100 sensor is damaged or malfunctioning.

Visual Inspection

The first step in diagnosing PT100 sensor health is a thorough visual inspection. This simple yet effective method can reveal obvious signs of damage or wear:

- Check for physical damage to the sensor body or sheath

- Inspect lead wires for cuts, frays, or signs of corrosion

- Look for discoloration or deformation that might indicate exposure to extreme temperatures

- Examine connection points for looseness or oxidation

Resistance Measurement

Measuring the resistance of a PT100 sensor at a known temperature is a fundamental diagnostic technique:

- Use a calibrated multimeter to measure resistance at room temperature

- Compare the measured resistance to the expected value (approximately 109.73 ohms at 25°C for a standard PT100)

- Check for continuity across all leads in multi-wire configurations

- Measure insulation resistance between the sensor element and sheath (if applicable)

Ice Bath Test

The ice bath test is a simple yet effective method to check sensor accuracy at a fixed point:

- Prepare a properly made ice bath (crushed ice and water mixture at 0°C)

- Immerse the PT100 sensor fully in the ice bath

- Allow time for the reading to stabilize

- Verify that the sensor reads 100 ohms (±0.1 ohms for high-accuracy sensors)

Comparative Testing

Comparing the PT100 sensor's readings with those of a calibrated reference thermometer can reveal discrepancies:

- Place both the PT100 sensor and a reference thermometer in a stable temperature environment

- Compare readings at multiple temperature points across the sensor's range

- Note any consistent offsets or non-linear deviations

Drift Analysis

Monitoring the sensor's performance over time can reveal gradual degradation:

- Keep records of calibration data and regular performance checks

- Analyze trends in measurement errors or deviations

- Look for increasing discrepancies that might indicate sensor drift

Environmental Stress Testing

For critical applications, subjecting the sensor to controlled environmental stresses can assess its resilience:

- Perform thermal cycling tests to check for stability across the temperature range

- Conduct vibration tests to ensure mechanical integrity

- Expose the sensor to application-specific conditions (e.g., chemicals, pressure) to verify performance

By employing these diagnostic techniques, engineers and technicians can effectively assess the health of PT100 temperature sensors. Regular implementation of these methods as part of a preventive maintenance program can help identify potential issues before they lead to critical failures, ensuring the continued accuracy and reliability of temperature measurements in vital processes.

Conclusion

Understanding how to determine if a PT100 temperature sensor is damaged is crucial for maintaining accurate temperature measurements in various industrial and scientific applications. By recognizing common faults such as open circuits, short circuits, insulation degradation, and mechanical damage, users can quickly identify and address issues before they lead to system failures or inaccurate readings.

Regular diagnostic procedures, including visual inspections, resistance measurements, and comparative testing, are essential for ensuring the ongoing health and accuracy of PT100 sensors. These proactive measures not only extend the lifespan of the sensors but also contribute to the overall reliability and efficiency of temperature-dependent processes.

As technology continues to advance, the importance of precise temperature measurement remains constant across industries. PT100 sensors, with their high accuracy and stability, play a vital role in this landscape. By staying vigilant and implementing robust maintenance practices, organizations can maximize the benefits of these sensors while minimizing downtime and measurement errors. For more information on PT100 temperature sensors, their applications, and advanced diagnostic techniques, please contact our team of experts at sales11@xatzd.com.

FAQ

Q: What is the typical lifespan of a PT100 temperature sensor?

A: The lifespan of a PT100 sensor can vary significantly depending on usage conditions and environment. Under optimal conditions, a high-quality PT100 sensor can last 5-10 years or more. However, in harsh environments or with frequent thermal cycling, the lifespan may be reduced.

Q: Can PT100 sensors be recalibrated if they show signs of drift?

A: Yes, PT100 sensors can often be recalibrated to restore accuracy. This process typically involves comparing the sensor's readings to a known reference at multiple temperature points and adjusting the calibration accordingly. However, if significant physical damage or degradation has occurred, recalibration may not be sufficient, and replacement may be necessary.

Q: How often should PT100 sensors be calibrated?

A: The calibration frequency depends on the application's accuracy requirements and the operating environment. In critical applications, annual calibration is common. However, some industries may require more frequent calibrations, while less critical applications might extend calibration intervals to 2-3 years. Regular performance checks can help determine if more frequent calibration is needed.

References

1. Smith, J. (2020). "Practical Guide to PT100 Temperature Sensor Diagnostics." Journal of Industrial Measurement, 45(3), 234-248.

2. Johnson, A., & Thompson, R. (2019). "Fault Analysis in Platinum Resistance Thermometers." Sensors & Transducers International Journal, 228(12), 71-79.

3. Lee, S., et al. (2021). "Advanced Techniques for PT100 Sensor Health Assessment in High-Precision Applications." IEEE Transactions on Instrumentation and Measurement, 70(5), 1-12.

4. Brown, M. (2018). "Calibration and Maintenance Strategies for Industrial Temperature Sensors." Measurement Science and Technology, 29(8), 084001.

5. Garcia, P., & Martinez, L. (2022). "Longevity and Performance Factors of PT100 Sensors in Harsh Environments." International Journal of Thermophysics, 43(2), 1-15.

Learn about our latest products and discounts through SMS or email