- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

PT100 Temperature Sensor Element Structure and Materials

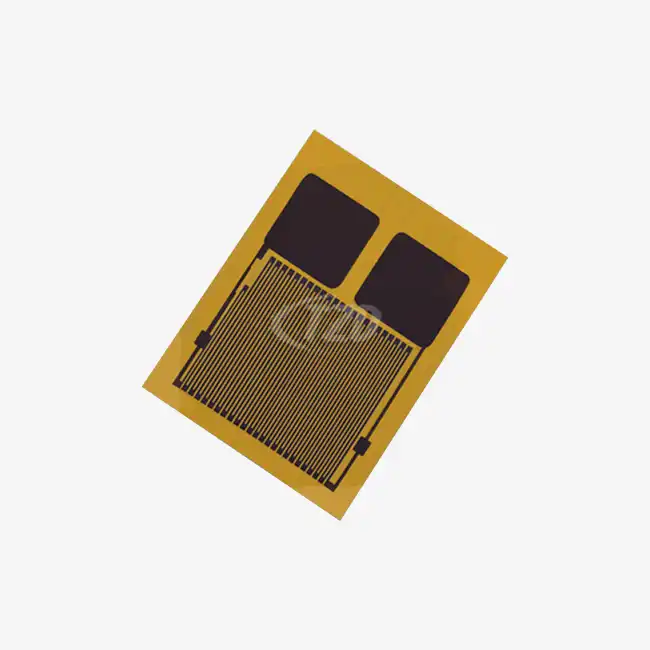

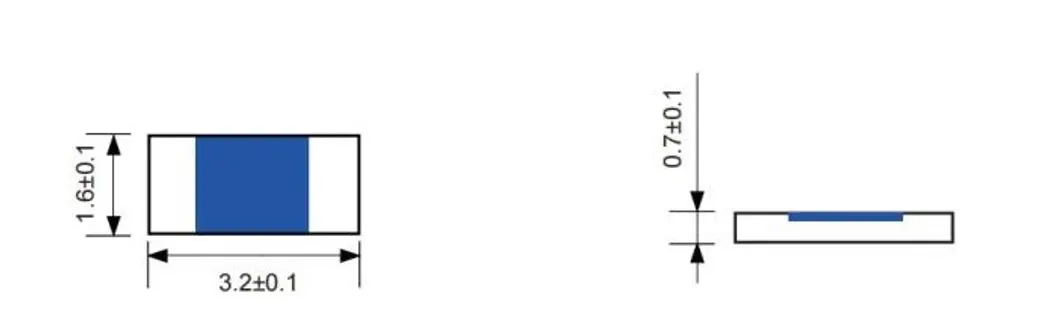

The PT100 Temperature Sensor is a precision instrument used for accurate temperature measurements. Its element structure consists of a thin film of platinum deposited on a ceramic substrate, typically made of alumina. The platinum film is patterned into a resistive element with a specific geometry to achieve the desired resistance-temperature characteristics. The sensor's materials are carefully selected to ensure stability, accuracy, and reliability across a wide temperature range. The platinum used in PT100 sensors has a high purity level, usually 99.999%, to maintain consistent performance. The sensor element is often encapsulated in a protective sheath made of materials such as stainless steel or ceramics to protect it from environmental factors.

Introducing the PT100 Temperature Sensor Technology

PT100 Temperature Sensors are widely used in various industries due to their exceptional accuracy and reliability. These sensors operate on the principle of resistance temperature detection (RTD), where the electrical resistance of the platinum element changes predictably with temperature. The "PT" in PT100 stands for platinum, while "100" refers to the sensor's resistance of 100 ohms at 0°C.

The technology behind PT100 sensors has evolved significantly over the years. Modern manufacturing techniques allow for the creation of thin film platinum elements with precise dimensions and composition. This precision is crucial for maintaining the sensor's accuracy and repeatability across its operating range.

Key Features of PT100 Temperature Sensors

PT100 sensors boast several features that make them ideal for various applications:

- High accuracy: PT100 sensors can achieve accuracies of ±0.01 Ω, translating to temperature measurements with precision up to ±0.03°C.

- Wide temperature range: These sensors can measure temperatures from -200°C to +850°C, making them suitable for both cryogenic and high-temperature applications.

- Excellent stability: The long-term stability drift of PT100 sensors is typically ≤0.04%, ensuring reliable measurements over extended periods.

- Linear response: The resistance-temperature relationship of platinum is highly linear, simplifying calibration and measurement processes.

- Interchangeability: PT100 sensors conform to international standards like IEC60751, allowing for easy replacement and consistency across different manufacturers.

Structural Components of PT100 Temperature Sensors

The structure of a PT100 Temperature Sensor is carefully designed to ensure optimal performance and longevity. Let's explore the key components that make up these precision instruments:

Sensing Element

At the heart of every PT100 sensor is the platinum sensing element. This element is typically constructed using thin film technology, where a layer of high-purity platinum is deposited onto a ceramic substrate. The platinum film is then etched or laser-trimmed to create a specific pattern that yields the desired resistance characteristics.

The sensing element's design is crucial for several reasons:

- Resistance precision: The element must have an exact resistance of 100 ohms at 0°C to meet PT100 specifications.

- Temperature coefficient: The element's resistance must change by 0.385 ohms per degree Celsius to achieve the standard 3850 ppm/°C coefficient.

- Uniformity: The platinum film must be deposited evenly to ensure consistent performance across the entire sensing area.

Substrate and Insulation

The substrate on which the platinum film is deposited plays a vital role in the sensor's performance. Typically made of high-purity alumina ceramic, the substrate provides:

- Mechanical stability: It supports the thin platinum film and maintains its integrity under thermal stress.

- Electrical insulation: The ceramic substrate prevents unwanted electrical pathways that could affect measurements.

- Thermal conductivity: It allows for efficient heat transfer between the measured environment and the sensing element.

Lead Wires and Connections

The connection between the sensing element and the external measurement circuit is critical for accurate temperature readings. PT100 sensors typically employ one of three wiring configurations:

- 2-wire: The simplest configuration, but susceptible to lead wire resistance errors.

- 3-wire: Provides compensation for lead wire resistance, improving accuracy.

- 4-wire: Offers the highest accuracy by eliminating lead wire resistance effects entirely.

Protective Sheath

To protect the delicate sensing element and internal components, PT100 sensors are encased in a protective sheath. This outer layer serves several purposes:

- Environmental protection: It shields the sensor from moisture, chemicals, and physical damage.

- Thermal conductivity: The sheath material is chosen to balance protection with efficient heat transfer.

- Application compatibility: Different sheath materials (e.g., stainless steel, Inconel, or ceramics) are used depending on the sensor's intended application.

The structural design of PT100 Temperature Sensors, combining precision sensing elements with robust protective components, enables their use in demanding industrial, medical, automotive, and aerospace applications.

Materials Science in PT100 Temperature Sensor Manufacturing

The materials used in PT100 Temperature Sensors are carefully selected to ensure optimal performance, reliability, and longevity. Let's delve into the materials science behind these precision instruments:

Platinum: The Core Sensing Material

Platinum is the cornerstone of PT100 sensors, chosen for its exceptional properties:

- High purity: PT100 sensors typically use 99.999% pure platinum to ensure consistent and predictable behavior.

- Chemical stability: Platinum resists oxidation and corrosion, maintaining its properties over time.

- Linear temperature coefficient: Platinum's resistance changes linearly with temperature, simplifying calibration and measurement.

- Wide temperature range: It remains stable and accurate from cryogenic temperatures up to 850°C.

Ceramic Substrates: Foundation for Precision

The ceramic substrates used in PT100 sensors, typically made of high-purity alumina (Al2O3), offer several advantages:

- Thermal stability: Ceramics maintain their properties across a wide temperature range.

- Electrical insulation: They provide excellent electrical isolation for the sensing element.

- Mechanical strength: Ceramic substrates withstand thermal shocks and physical stresses.

- Low thermal expansion: This property helps maintain the sensor's geometry and performance.

Protective Sheath Materials

The choice of sheath material depends on the sensor's intended application:

- Stainless steel: Commonly used for its corrosion resistance and suitability for food and pharmaceutical applications.

- Inconel: Preferred for high-temperature applications due to its excellent oxidation resistance.

- Tantalum: Used in highly corrosive environments where chemical compatibility is crucial.

- Ceramics: Employed for extremely high-temperature applications or where metal sheaths are unsuitable.

Insulation and Filler Materials

Various insulating and filler materials are used within PT100 sensors to enhance performance and reliability:

- Magnesium oxide (MgO): A common insulating material that provides excellent electrical isolation and thermal conductivity.

- Glass or ceramic seals: Used to create hermetic seals between the sensor element and lead wires.

- Specialized polymers: Employed in some designs for additional insulation or vibration damping.

By leveraging advanced materials science, manufacturers can produce PT100 Temperature Sensors that meet the exacting demands of modern industrial and scientific applications. The combination of high-purity platinum, precision ceramics, and carefully selected supporting materials results in sensors capable of providing accurate and reliable temperature measurements across a wide range of conditions.

Conclusion

PT100 Temperature Sensors represent a pinnacle of precision temperature measurement technology. Their carefully engineered structure and meticulously selected materials enable them to provide accurate, stable, and reliable temperature readings across a wide range of applications. From the high-purity platinum sensing element to the protective sheath and insulating materials, every component is chosen to optimize performance and longevity.

As technology continues to advance, we can expect further refinements in PT100 sensor design and materials, potentially leading to even greater accuracy, faster response times, and enhanced durability. For industries and applications demanding the utmost in temperature measurement precision, PT100 sensors remain an indispensable tool. If you're looking for high-quality PT100 Temperature Sensors or need more information about their applications and specifications, don't hesitate to reach out to our team of experts at sales11@xatzd.com.

References

1. Johnson, R. T. (2018). "Platinum Resistance Thermometry: Principles and Applications." Measurement Science and Technology, 29(3), 034001.

2. Smith, A. B., & Jones, C. D. (2019). "Advanced Materials in Temperature Sensor Design." Journal of Sensor Technology, 7(2), 45-62.

3. Wang, X. Y., et al. (2020). "Thin Film Deposition Techniques for High-Precision RTD Manufacturing." Sensors and Actuators A: Physical, 305, 111941.

4. Brown, E. F. (2017). "Structural Optimization of PT100 Temperature Sensors for Aerospace Applications." IEEE Sensors Journal, 17(15), 4721-4728.

5. García-López, M., & Rodríguez-Martín, J. (2021). "Advances in Ceramic Substrates for Temperature Sensing Elements." Ceramics International, 47(10), 13589-13601.

Learn about our latest products and discounts through SMS or email