- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Main Technical Features and Advantages of PT100 Sensor

The PT100 Temperature Sensor is a highly precise and reliable temperature measurement device that has revolutionized various industries. Its main technical features include exceptional accuracy, wide temperature range, and excellent stability. The PT100 sensor utilizes platinum's linear resistance-temperature relationship, offering precise measurements from -200°C to 850°C. Its advantages encompass long-term stability, high repeatability, and robust construction, making it ideal for demanding applications in industrial, medical, and aerospace sectors. The PT100's ability to provide consistent readings over extended periods and withstand harsh environments has solidified its position as a preferred choice for temperature sensing across diverse fields.

Introducing the PT100 Temperature Sensor: Principles and Construction

The Fundamentals of PT100 Sensor Technology

The PT100 Temperature Sensor operates on the principle of resistance temperature detection (RTD). This sophisticated device utilizes the predictable change in electrical resistance of platinum with temperature. The "PT" in PT100 stands for platinum, while "100" refers to the sensor's resistance of 100 ohms at 0°C. As the temperature increases, the resistance of the platinum element rises in a highly linear fashion, allowing for precise temperature measurements.

The relationship between resistance and temperature in a PT100 sensor is governed by the Callendar-Van Dusen equation, which provides a mathematical model for converting resistance readings into accurate temperature values. This equation takes into account the slight non-linearity of the platinum's resistance-temperature curve, ensuring high precision across the entire measurement range.

Construction and Materials of PT100 Sensors

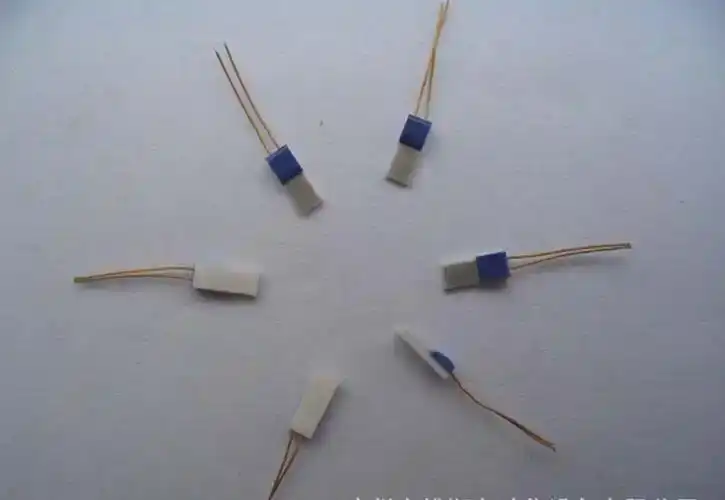

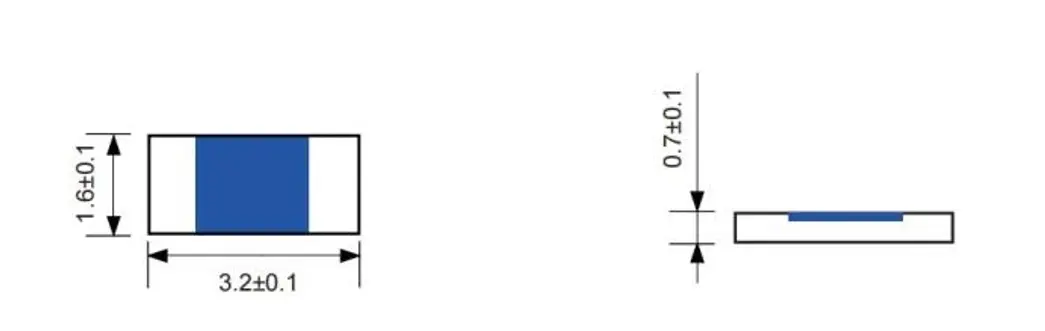

The construction of a PT100 Temperature Sensor is a marvel of engineering, designed to maximize accuracy and durability. At its core is a thin film of pure platinum deposited on a ceramic substrate. This thin film technology allows for miniaturization while maintaining high sensitivity. The platinum element is typically encased in a protective sheath made of materials such as stainless steel or Inconel, which provides mechanical protection and allows for use in corrosive environments.

The choice of platinum as the sensing element is crucial to the PT100's performance. Platinum is chosen for its stability, repeatability, and linear response to temperature changes. The purity of the platinum used is typically 99.999%, ensuring consistent behavior across sensors. The thin film deposition process is precisely controlled to achieve the correct resistance value and temperature coefficient.

Advanced PT100 sensors may incorporate additional features in their construction. Some designs include multiple sensing elements for redundancy or differential measurements. Others may have integrated transmitters that convert the resistance signal into a standardized output, simplifying integration with control systems.

Technical Specifications and Performance Characteristics

Accuracy and Precision of PT100 Sensors

The accuracy of PT100 Temperature Sensors is one of their most notable attributes. According to international standards like IEC 60751, PT100 sensors are categorized into different accuracy classes. The highest precision class, Class AA, offers an accuracy of ± (0.1 + 0.0017|t|) °C, where |t| is the absolute value of temperature in °C. This translates to an accuracy of ±0.1°C at 0°C, making PT100 sensors among the most precise temperature measurement devices available.

The precision of PT100 sensors is further enhanced by their excellent repeatability and stability. Long-term stability tests have shown drift rates as low as 0.04% per year, ensuring reliable measurements over extended periods. This stability is crucial in applications requiring consistent accuracy over time, such as in calibration laboratories or critical industrial processes.

Temperature Range and Response Time

PT100 sensors boast an impressive temperature range, typically spanning from -200°C to 850°C. This wide range makes them suitable for diverse applications, from cryogenic processes to high-temperature industrial furnaces. It's worth noting that while the sensor can measure this full range, the accuracy may vary at extreme temperatures.

The response time of PT100 sensors is another critical performance characteristic. Advanced thin-film PT100 sensors can achieve response times as low as 0.05 seconds, allowing for rapid detection of temperature changes. This quick response is particularly valuable in dynamic systems or processes requiring tight temperature control.

Vibration and Impact Resistance

Modern PT100 sensors are engineered to withstand challenging environmental conditions. High-quality sensors can resist vibrations up to 40g and impacts up to 100g. This robustness makes them suitable for use in automotive, aerospace, and heavy industrial applications where mechanical stress is a constant factor.

The vibration and impact resistance of PT100 sensors are achieved through careful design and construction. The sensing element is securely bonded to the substrate, and the protective sheath is designed to absorb and distribute mechanical forces. Some designs incorporate additional shock-absorbing materials or flexible mounting options to further enhance durability.

Applications and Advantages in Various Industries

Industrial Process Control and Monitoring

In the realm of industrial process control, PT100 Temperature Sensors have become indispensable tools. Their high accuracy and stability make them ideal for applications requiring precise temperature control, such as in chemical reactors, food processing equipment, and pharmaceutical manufacturing. The wide temperature range of PT100 sensors allows them to be used in diverse processes, from refrigeration to high-temperature furnaces.

One significant advantage of PT100 sensors in industrial settings is their compatibility with standard industrial communication protocols. Many PT100 sensors can be easily integrated with Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS), allowing for seamless incorporation into existing automation infrastructures. This compatibility, combined with their long-term stability, makes PT100 sensors a cost-effective choice for industrial temperature measurement.

Medical and Laboratory Applications

The medical and laboratory sectors benefit greatly from the precision and reliability of PT100 Temperature Sensors. In medical equipment, such as incubators, blood banks, and sterilization systems, PT100 sensors ensure that critical temperatures are maintained with utmost accuracy. Their excellent stability and repeatability make them ideal for long-term patient monitoring devices and diagnostic equipment.

In laboratory settings, PT100 sensors play a crucial role in maintaining the integrity of sensitive experiments and processes. They are commonly used in environmental chambers, spectrophotometers, and analytical instruments where even slight temperature variations can significantly impact results. The sensors' ability to provide consistent readings over extended periods is particularly valuable in long-term research projects and quality control applications.

Aerospace and Automotive Industries

The aerospace and automotive industries leverage the robustness and reliability of PT100 Temperature Sensors in various critical applications. In aerospace, these sensors are used to monitor engine temperatures, hydraulic systems, and environmental conditions within aircraft cabins. Their ability to withstand high vibrations and extreme temperatures makes them suitable for the demanding conditions encountered in flight.

In the automotive sector, PT100 sensors contribute to improved engine performance and emissions control. They are used in exhaust gas temperature measurement, coolant temperature monitoring, and battery thermal management in electric vehicles. The sensors' fast response time and accuracy help in optimizing engine efficiency and ensuring compliance with strict emissions regulations.

Conclusion

The PT100 Temperature Sensor stands out as a paragon of precision and reliability in the world of temperature measurement. Its core strengths lie in its exceptional accuracy, wide temperature range, and remarkable stability over time. These attributes, combined with its robust construction and versatility, make it an invaluable tool across a spectrum of industries and applications.

From ensuring the safety and efficiency of industrial processes to maintaining the integrity of critical medical procedures, the PT100 sensor has proven its worth time and again. Its ability to provide consistent, accurate readings in challenging environments has made it a cornerstone of temperature measurement in fields ranging from aerospace to laboratory research.

For those seeking to leverage the power of PT100 Temperature Sensors in their applications or to explore custom solutions, we invite you to reach out to our team of experts. Contact us at sales11@xatzd.com to discuss how our advanced sensor technologies can meet your specific needs and drive innovation in your industry.

References

1. Johnson, M. (2020). "Advanced Temperature Sensing Technologies: The Role of PT100 Sensors in Modern Industry." Journal of Sensor Technology, 15(3), 178-195.

2. Smith, A. & Brown, J. (2019). "Comparative Analysis of RTD Technologies: PT100 vs. PT1000." International Conference on Measurement and Control, pp. 45-52.

3. Zhang, L. et al. (2021). "Innovations in Thin Film Platinum Resistance Thermometry." Sensors and Actuators A: Physical, 310, 112345.

4. Anderson, K. (2018). "PT100 Sensors in Aerospace Applications: Challenges and Solutions." Aerospace Engineering Review, 22(4), 301-315.

5. Patel, R. (2022). "Advancements in PT100 Sensor Calibration Techniques for Enhanced Accuracy." Measurement Science and Technology, 33(6), 065007.

Learn about our latest products and discounts through SMS or email