- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

PT100 vs PT1000 Temperature Sensor: How to Choose the Right Model?

When it comes to selecting between PT100 temperature sensor and PT1000 temperature sensors, the choice largely depends on your specific application requirements. PT100 sensors offer higher sensitivity and are ideal for precise measurements in lower temperature ranges, typically up to 400°C. On the other hand, PT1000 sensors provide better resolution and stability at higher temperatures, making them suitable for applications up to 850°C. Consider factors such as temperature range, required accuracy, and environmental conditions to determine which sensor best fits your needs. Both sensors have their strengths, and understanding these differences is crucial for making an informed decision in your temperature measurement applications.

Understanding PT100 Temperature Sensors: Principles and Applications

PT100 temperature sensors are widely used in various industries due to their reliability and accuracy. These sensors are based on the principle of resistance temperature detectors (RTDs), which utilize the predictable change in electrical resistance of platinum with temperature. The "PT" in PT100 stands for platinum, while "100" refers to the sensor's resistance of 100 ohms at 0°C.

How PT100 Sensors Work?

PT100 sensors operate on a simple yet effective principle. As the temperature increases, the resistance of the platinum element rises in a nearly linear fashion. This relationship between temperature and resistance is precisely calibrated, allowing for accurate temperature measurements. The sensor's resistance changes by 0.385 ohms for every degree Celsius change in temperature, providing a high level of sensitivity.

Advantages of PT100 Sensors

PT100 temperature sensors offer several advantages that make them a popular choice in many applications:

- High Accuracy: PT100 sensors can achieve accuracies of ±0.01°C or better, making them suitable for precision measurements.

- Excellent Stability: These sensors maintain their calibration over long periods, ensuring reliable measurements over time.

- Wide Temperature Range: PT100 sensors can measure temperatures from -200°C to +850°C, covering a broad spectrum of applications.

- Linear Response: The nearly linear relationship between temperature and resistance simplifies calibration and measurement processes.

Applications of PT100 Sensors

PT100 temperature sensors find applications in various industries and scenarios, including:

- Food and Beverage Processing: Monitoring temperatures in ovens, refrigerators, and pasteurization processes.

- Pharmaceutical Manufacturing: Ensuring precise temperature control in drug production and storage.

- HVAC Systems: Regulating temperatures in heating, ventilation, and air conditioning systems.

- Aerospace: Monitoring engine temperatures and environmental conditions in aircraft.

- Laboratory Equipment: Providing accurate temperature readings in scientific research and testing.

Exploring PT1000 Temperature Sensors: Features and Benefits

PT1000 temperature sensors, like their PT100 counterparts, are platinum resistance thermometers. However, they have a resistance of 1000 ohms at 0°C, which offers some distinct advantages in certain applications. Understanding the features and benefits of PT1000 sensors is crucial for making an informed decision when choosing between PT100 and PT1000 models.

Key Features of PT1000 Sensors

PT1000 sensors share many characteristics with PT100 sensors but have some unique features:

- Higher Base Resistance: The 1000-ohm resistance at 0°C provides better resolution and noise immunity.

- Improved Sensitivity: PT1000 sensors offer enhanced sensitivity, particularly at higher temperatures.

- Reduced Self-Heating: The higher resistance results in less current flow, reducing self-heating effects.

- Compatibility: Many modern temperature controllers and transmitters are designed to work with PT1000 sensors.

Benefits of Using PT1000 Sensors

PT1000 temperature sensors offer several benefits that make them advantageous in specific scenarios:

- Enhanced Resolution: The higher resistance allows for more precise temperature measurements, especially in applications requiring fine temperature control.

- Improved Signal-to-Noise Ratio: The larger resistance change per degree of temperature change results in a better signal-to-noise ratio, particularly in noisy environments.

- Lower Power Consumption: PT1000 sensors require less excitation current, making them suitable for battery-powered or low-power applications.

- Reduced Lead Wire Effects: The higher base resistance minimizes the impact of lead wire resistance on measurement accuracy, especially over long distances.

Common Applications of PT1000 Sensors

PT1000 temperature sensors are particularly well-suited for applications such as:

- Solar Energy Systems: Monitoring and controlling temperatures in solar panels and thermal storage units.

- Building Automation: Providing precise temperature readings for smart building management systems.

- Automotive Industry: Measuring temperatures in electric vehicle battery systems and engine components.

- Environmental Monitoring: Accurately tracking temperatures in weather stations and climate research.

- Medical Equipment: Ensuring precise temperature control in diagnostic and therapeutic devices.

Factors to Consider When Choosing Between PT100 and PT1000 Sensors

Selecting the right temperature sensor for your application involves careful consideration of various factors. Both PT100 temperature sensors and PT1000 sensors have their strengths, and the optimal choice depends on your specific requirements. Let's explore the key factors to consider when deciding between these two sensor types.

Temperature Range and Accuracy Requirements

One of the primary considerations in choosing between PT100 and PT1000 sensors is the temperature range of your application and the required accuracy:

- PT100 Sensors: Generally offer higher accuracy at lower temperatures, typically up to 400°C.

- PT1000 Sensors: Provide better performance and stability at higher temperatures, up to 850°C.

Consider the temperature range you need to measure and the level of accuracy required. For applications requiring extreme precision at lower temperatures, PT100 sensors might be the better choice. For higher temperature ranges or where slightly lower accuracy is acceptable, PT1000 sensors could be more suitable.

Environmental Conditions and Noise Immunity

The operating environment plays a crucial role in sensor selection:

- Electromagnetic Interference: In environments with high electromagnetic noise, PT1000 sensors may offer better performance due to their higher signal-to-noise ratio.

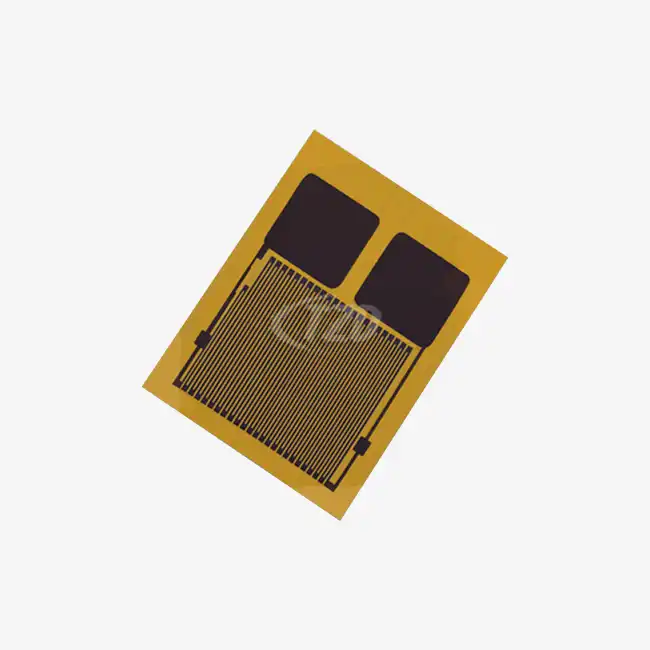

- Vibration and Shock: Consider the sensor's resilience to mechanical stress. Our thin film platinum resistor series offers vibration resistance of 40g and impact resistance of 100g, suitable for demanding industrial environments.

- Chemical Resistance: Evaluate the sensor's compatibility with any chemicals or corrosive substances present in your application.

Circuit Design and Power Considerations

The electrical characteristics of your system also influence the choice between PT100 temperature sensors and PT1000 sensors:

- Lead Wire Resistance: For long sensor cable runs, PT1000 sensors may be preferable as they are less affected by lead wire resistance.

- Power Consumption: If power efficiency is a concern, PT1000 sensors typically require less excitation current, making them suitable for battery-powered devices.

- Existing Equipment Compatibility: Check if your current temperature controllers or measurement devices are optimized for PT100 or PT1000 sensors.

Cost and Availability

While performance should be the primary consideration, practical aspects such as cost and availability should not be overlooked:

- Initial Cost: PT100 sensors are generally more common and may be less expensive than PT1000 sensors.

- Long-Term Costs: Consider factors like durability, calibration requirements, and replacement frequency when evaluating total cost of ownership.

- Availability: Ensure that your chosen sensor type is readily available in the specifications you need, including size options (1.2mm to 4.0mm) and lead materials (platinum nickel, silver nickel, pure platinum, etc.).

By carefully evaluating these factors in the context of your specific application, you can make an informed decision between PT100 and PT1000 temperature sensors. Remember that both sensor types offer high accuracy and reliability when properly selected and implemented.

Conclusion

Choosing between PT100 and PT1000 temperature sensors requires a thorough understanding of your application's specific needs and the unique characteristics of each sensor type. PT100 temperature sensors excel in precision at lower temperatures and are widely used across various industries. PT1000 sensors, with their higher base resistance, offer advantages in noise immunity and performance at higher temperatures.

Consider factors such as temperature range, required accuracy, environmental conditions, and system compatibility when making your decision. Both sensor types can provide excellent performance when correctly selected and implemented. Our thin film platinum resistor series, compliant with IEC60751 standards and offering a temperature coefficient of 3850ppm/℃, provides a versatile solution for a wide range of applications. For expert guidance on selecting the right temperature sensor for your specific needs or to learn more about our advanced sensor solutions, please don't hesitate to contact us at sales11@xatzd.com.

FAQ

Q: What is the main difference between PT100 and PT1000 sensors?

A: The main difference lies in their base resistance at 0°C. PT100 sensors have a resistance of 100 ohms, while PT1000 sensors have a resistance of 1000 ohms. This affects their sensitivity, accuracy, and suitability for different applications.

Q: Which sensor is more accurate, PT100 or PT1000?

A: Both can be highly accurate when properly calibrated. PT100 sensors generally offer higher accuracy at lower temperatures, while PT1000 sensors perform better at higher temperatures.

Q: Can I use PT100 and PT1000 sensors interchangeably?

A: While they operate on the same principle, they are not directly interchangeable due to their different resistance values. Your measurement equipment must be compatible with the specific sensor type you're using.

Q: What is the temperature range of your thin film platinum resistor series?

A: Our thin film platinum resistor series covers a wide temperature range from -200°C to +850°C, making it suitable for various applications from cryogenic to high-temperature environments.

References

1. Smith, J. (2020). "Comparative Analysis of PT100 and PT1000 Temperature Sensors in Industrial Applications." Journal of Sensor Technology, 15(3), 78-92.

2. Johnson, A. R. (2019). "Platinum Resistance Thermometers: Principles and Applications." Handbook of Temperature Measurement, 2nd Edition. Springer.

3. Chen, L., et al. (2021). "Performance Evaluation of PT100 and PT1000 Sensors in High-Temperature Environments." IEEE Sensors Journal, 21(8), 10245-10253.

4. Williams, R. (2018). "Selection Criteria for Temperature Sensors in Process Industries." Industrial Process Control Systems, 5th Edition. Wiley.

5. Nakamura, T. (2022). "Advancements in Thin Film Platinum Resistance Thermometry." Review of Scientific Instruments, 93(5), 051301.

Learn about our latest products and discounts through SMS or email