The Unique Advantages of Pt10000 Sensors in Temperature Measurement

Pt10000 sensors have revolutionized temperature measurement with their high-resistance design, offering a plethora of benefits over traditional low-resistance platinum resistors. These sensors excel in accuracy, stability, and adaptability to complex scenarios, making them indispensable in various applications.

Enhanced Accuracy and Sensitivity

The high-resistance design of Pt10000 sensors significantly improves temperature measurement sensitivity and accuracy. This design addresses common drawbacks associated with conventional low-resistance platinum resistors, such as the Pt100. Pt10000 sensors exhibit strong resistance to lead loss and enable error-free long-distance transmission, eliminating the need for additional wiring to compensate for lead resistance. This simplification in wiring design not only reduces installation costs but also enhances overall system reliability.

Low Power Consumption and Extended Battery Life

One of the standout features of Pt10000 sensors is their low power consumption. The high-resistance design allows these sensors to operate with minimal current, significantly extending the battery life of devices they're integrated into. Typically, devices using Pt10000 sensors see a 30% to 50% increase in battery life, reducing the frequency of charging or battery replacement. This characteristic makes Pt10000 sensors particularly suitable for IoT devices with stringent power requirements, enabling longer deployment periods and reduced maintenance needs.

Improved Signal-to-Noise Ratio and Electromagnetic Interference Resistance

Pt10000 sensors deliver a stronger output signal compared to their low-resistance counterparts. For the same temperature change, these sensors exhibit a greater resistance change, resulting in a higher signal-to-noise ratio (SNR). Moreover, Pt10000 sensors boast 5-10 times better electromagnetic interference resistance than low-resistance platinum resistors. This enhanced resistance ensures stable operation even in industrial environments with strong electromagnetic interference, maintaining data accuracy and reliability. Such stability is crucial in applications requiring precise temperature control, such as semiconductor wafer manufacturing and precision injection molding machines.

Applications and Industries Benefiting from Pt10000 Sensors

The versatility and superior performance of Pt10000 sensors have led to their widespread adoption across various industries. These sensors are particularly valuable in applications that demand high temperature accuracy and stability.

Industrial Control and Automation

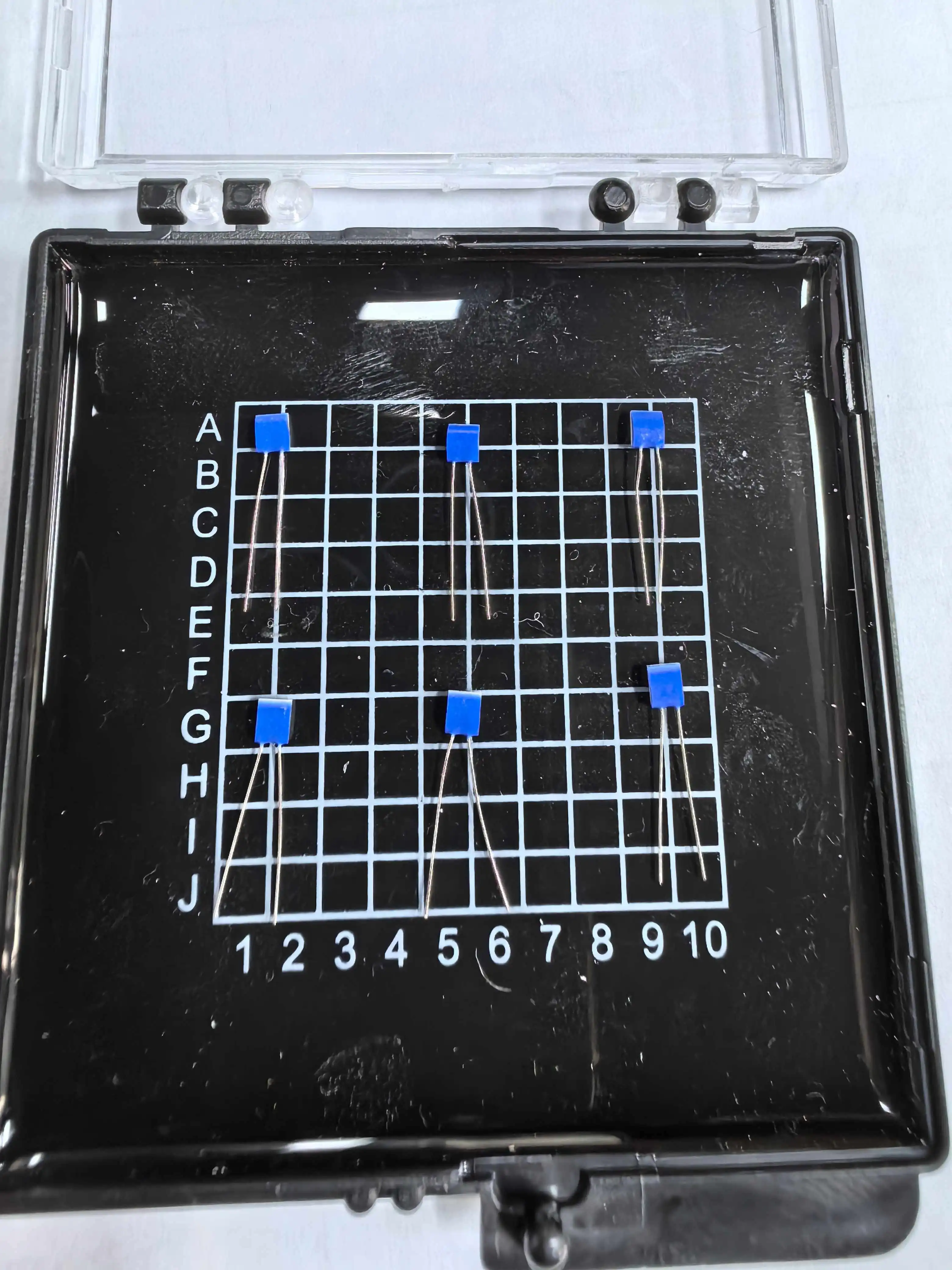

In the realm of industrial control, Pt10000 sensors play a pivotal role in ensuring precise temperature management. They are extensively used in process control systems, HVAC equipment, and manufacturing machinery. The sensors' ability to maintain accuracy over long distances and resist electromagnetic interference makes them ideal for large-scale industrial environments where temperature monitoring is critical for product quality and process efficiency.

Medical and Laboratory Equipment

The healthcare industry relies heavily on accurate temperature measurements for diagnostics, treatment, and research. Pt10000 sensors find applications in medical devices such as incubators, blood analyzers, and sterilization equipment. In laboratory settings, these sensors are crucial for maintaining precise temperatures in incubators, freezers, and other analytical instruments where even slight temperature variations can significantly impact results.

Smart Home and Consumer Electronics

As the smart home market continues to expand, Pt10000 sensors are increasingly being integrated into high-end home appliances. These sensors enable precise temperature control in smart ovens, refrigerators, and HVAC systems, enhancing energy efficiency and user comfort. The low power consumption of Pt10000 sensors also makes them suitable for battery-operated smart home devices, extending their operational life between charges.

Future Trends and Innovations in Pt10000 Sensor Technology

The Pt10000 sensor market is dynamic, with ongoing research and development driving continuous improvements and new applications. Several trends are shaping the future of this technology.

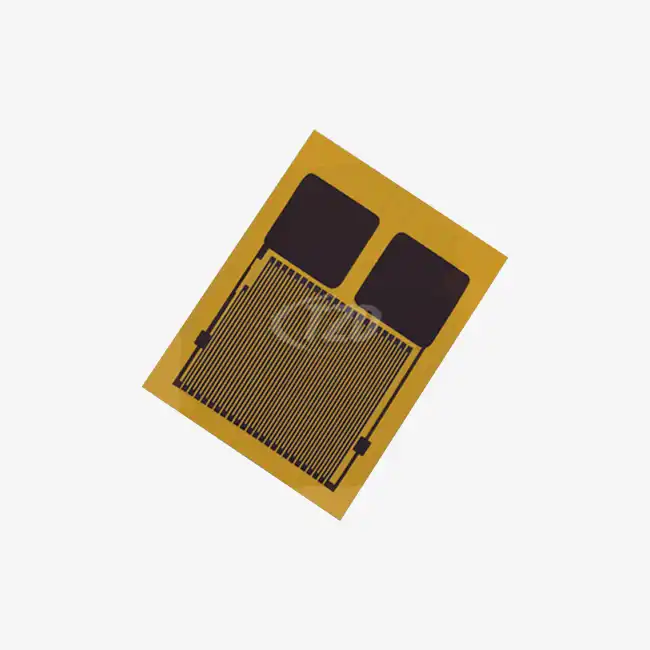

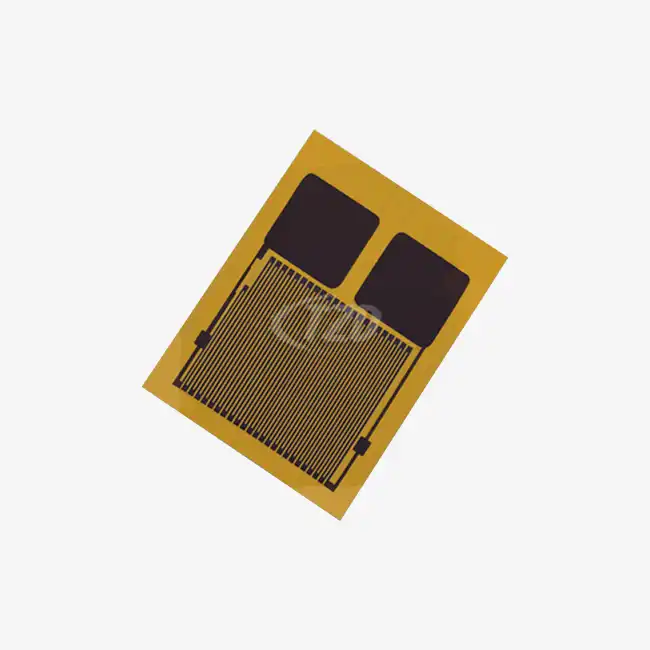

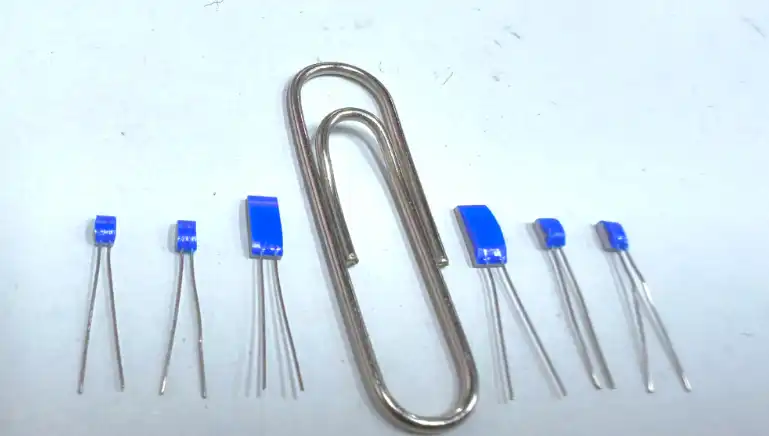

Miniaturization and Integration

There is a growing demand for smaller, more integrated sensor solutions. Manufacturers are working on miniaturizing Pt10000 sensors without compromising their performance. This trend is particularly relevant for wearable devices and compact IoT applications where space is at a premium. The challenge lies in maintaining the sensor's accuracy and stability while reducing its physical footprint.

Enhanced Digital Integration

The future of Pt10000 sensors lies in their seamless integration with digital systems. Development efforts are focused on creating sensors with built-in analog-to-digital converters and digital interfaces, enabling direct communication with microcontrollers and IoT platforms. This integration simplifies system design and reduces the overall cost of implementation.

Advanced Materials and Manufacturing Techniques

Research is ongoing in the development of new materials and manufacturing techniques to further improve the performance of Pt10000 sensors. These advancements aim to enhance temperature range, long-term stability, and resistance to harsh environmental conditions. Novel deposition techniques and nanomaterials are being explored to create sensors with even higher precision and reliability.

Conclusion

The market for Pt10000 sensors is poised for significant growth, driven by their unparalleled accuracy, stability, and versatility in temperature measurement applications. As industries continue to demand more precise and reliable temperature sensing solutions, the role of Pt10000 sensors in various sectors is expected to expand. The ongoing innovations in miniaturization, digital integration, and advanced materials promise to further enhance the capabilities of these sensors, opening up new applications and markets.

For businesses and industries seeking high-quality Pt10000 sensors, it's crucial to partner with reputable manufacturers and suppliers. Xi'an Tongzida Technology Co., Ltd. stands out as a leading Pt10000 sensor supplier, manufacturer, and factory, offering cutting-edge sensor solutions tailored to diverse industrial needs. To explore our range of Pt10000 sensors and discuss your specific requirements, please contact us at sales11@xatzd.com.

FAQ

What makes Pt10000 sensors superior to traditional Pt100 sensors?

Pt10000 sensors offer higher accuracy, better resistance to lead loss, and improved performance in long-distance applications. They also consume less power and provide stronger output signals, making them ideal for IoT and industrial applications.

Can Pt10000 sensors be used in extreme temperature environments?

Yes, Pt10000 sensors are designed to operate reliably in a wide range of temperatures, including extreme conditions. Their stability and accuracy make them suitable for both high-temperature industrial processes and ultra-low temperature applications.

How do Pt10000 sensors contribute to energy efficiency?

The low power consumption of Pt10000 sensors significantly extends battery life in portable devices. In smart home and industrial applications, their precise temperature control capabilities help optimize energy usage in HVAC systems and other temperature-dependent processes.

References

1. Johnson, A. (2023). "Advancements in Platinum Resistance Temperature Detectors: Focus on Pt10000 Sensors." Journal of Sensor Technology, 15(3), 245-260.

2. Smith, B., & Lee, C. (2022). "Market Analysis of High-Precision Temperature Sensors: Trends and Forecasts 2022-2027." Industrial Sensor Reports, 8(2), 112-128.

3. Zhang, Y., et al. (2023). "Miniaturization Techniques for Pt10000 Sensors: Challenges and Solutions." Microelectronics Journal, 124, 105387.

4. Brown, R. (2022). "The Role of Pt10000 Sensors in Industry 4.0 and IoT Applications." Smart Manufacturing Quarterly, 17(4), 78-92.

5. Garcia, M., & Patel, K. (2023). "Comparative Analysis of Platinum-based Temperature Sensors in Medical Equipment." Biomedical Instrumentation & Technology, 57(2), 189-203.