Miniaturization and Enhanced Precision in Pt1000 Temperature Sensors

The trend towards miniaturization is revolutionizing the world of Pt1000 temperature sensors. As industries demand more compact and efficient solutions, manufacturers are pushing the boundaries of sensor design. These smaller sensors are not just about saving space; they're opening up new possibilities for temperature measurement in previously inaccessible locations.

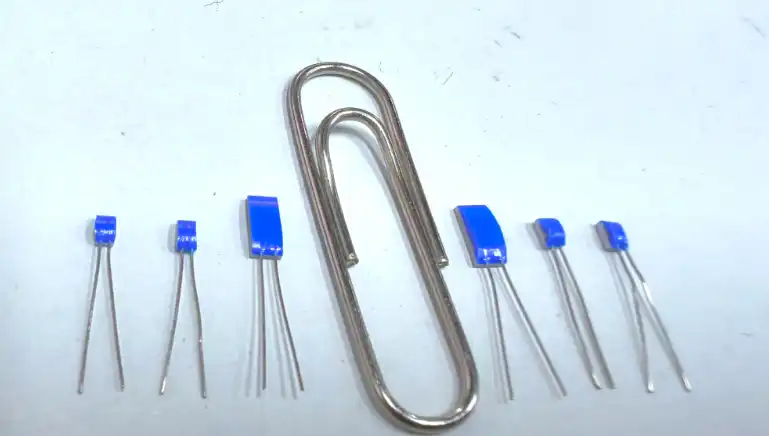

One of the most exciting developments is the creation of Pt1000 temperature sensors with element dimensions as small as 2.0mm x 2.3mm x 1.0mm. This reduction in size doesn't come at the cost of performance. In fact, these miniature sensors often boast improved response times. For instance, in water flow conditions (V=0.4 m/s), we're seeing response times as quick as t₀.₅ = 0.05 s and t₀.₉ = 0.15 s. This rapid response is crucial in industries where temperature changes need to be detected and acted upon swiftly.

Alongside miniaturization, there's a strong focus on enhancing the precision of Pt1000 temperature sensors. The industry is moving towards sensors with even higher temperature coefficients (TCR), surpassing the current standard of 3850 ppm/°C. This increased sensitivity allows for more accurate temperature readings across a wider range of temperatures.

Moreover, improvements in long-term stability are being made. Current high-quality Pt1000 sensors show a resistance drift of R₀ (0°C reference) of ≤±0.04% after 1000 hours at 500°C. Future developments aim to further reduce this drift, ensuring even more reliable measurements over extended periods.

Applications of Miniaturized Pt1000 Sensors

The miniaturization of Pt1000 temperature sensors is particularly beneficial in industries such as aerospace, automotive, and medical devices. In aerospace, these compact sensors can be integrated into critical components without adding significant weight or altering aerodynamics. In the automotive industry, they enable more precise temperature control in engine management systems, improving fuel efficiency and reducing emissions.

In the medical field, miniature Pt1000 sensors are finding applications in diagnostic equipment and implantable devices. Their small size and high accuracy make them ideal for monitoring body temperature in real-time, potentially revolutionizing patient care and treatment strategies.

Integration of Pt1000 Temperature Sensors with IoT and AI Technologies

The integration of Pt1000 temperature sensors with Internet of Things (IoT) and Artificial Intelligence (AI) technologies is set to transform industrial processes and maintenance strategies. This convergence is creating smarter, more responsive systems capable of real-time monitoring and predictive analytics.

IoT-enabled Pt1000 sensors can transmit temperature data continuously to cloud-based platforms. This constant stream of information allows for real-time monitoring of industrial processes, enabling immediate responses to temperature fluctuations. The ability to access this data remotely increases operational efficiency and reduces the need for on-site inspections.

When combined with AI algorithms, the data from these sensors becomes even more valuable. AI can analyze temperature patterns over time, identifying trends and anomalies that might be imperceptible to human observers. This capability is particularly useful in predictive maintenance scenarios. By detecting subtle changes in temperature profiles, AI systems can predict potential equipment failures before they occur, allowing for proactive maintenance and minimizing costly downtime.

The integration of Pt1000 sensors with IoT and AI also facilitates more sophisticated control systems. For instance, in industrial processes where temperature control is critical, AI-driven systems can make real-time adjustments based on sensor data, optimizing energy usage and product quality.

Enhanced Data Analytics and Decision Making

The combination of Pt1000 temperature sensors with advanced data analytics opens up new possibilities for process optimization. By analyzing historical temperature data alongside other variables like pressure, humidity, and production output, industries can gain deeper insights into their operations. This holistic approach to data analysis can lead to improved product quality, reduced waste, and increased energy efficiency.

Furthermore, the integration of these technologies is paving the way for more autonomous industrial systems. As AI becomes more sophisticated, we can expect to see systems that not only monitor and analyze temperature data but also make autonomous decisions to optimize processes based on this information.

Advancements in Materials and Manufacturing Techniques for Pt1000 Sensors

The future of Pt1000 temperature sensors is closely tied to advancements in materials science and manufacturing techniques. These developments are not only improving the performance of sensors but also making them more durable and cost-effective.

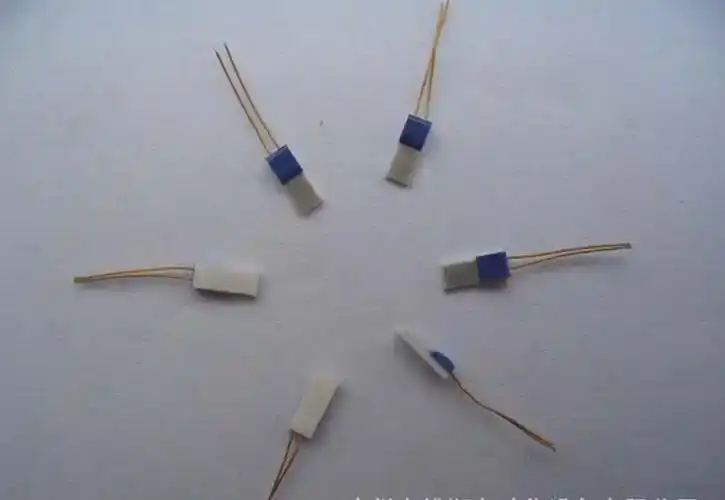

One area of focus is the development of new lead materials. While platinum-nickel wire is currently a popular choice, research is being conducted on alternative materials like silver-palladium alloys and pure silver. These materials could potentially offer improved conductivity and stability, particularly in high-temperature applications.

Innovations in thin film technology are also driving progress in Pt1000 sensor manufacturing. Advanced deposition techniques are allowing for the creation of extremely thin, yet highly uniform platinum layers. This results in sensors with faster response times and improved accuracy. For instance, current high-performance sensors can achieve a self-heating coefficient as low as 0.4°C/mW at 0°C, and future developments aim to reduce this even further.

Another significant trend is the improvement in sensor robustness. Future Pt1000 temperature sensors are expected to have even higher vibration and shock resistance. Current models can withstand vibrations of ≥40g acceleration in the frequency range of 10–2000 Hz and shocks of ≥100g acceleration (8 ms half-sine wave). Ongoing research is focused on pushing these limits further, making Pt1000 sensors suitable for even the most demanding industrial environments.

Sustainable Manufacturing and Recycling

As environmental concerns become increasingly important, the future of Pt1000 sensor manufacturing is likely to focus more on sustainability. This includes developing more energy-efficient production processes and exploring ways to recycle or repurpose sensors at the end of their lifecycle.

Additionally, there's a growing interest in bio-based and biodegradable materials for sensor packaging. While maintaining the integrity and performance of the sensor, these materials could significantly reduce the environmental impact of sensor production and disposal.

Conclusion

The future of Pt1000 temperature sensors in industry is bright and full of potential. From miniaturization and enhanced precision to integration with IoT and AI technologies, and advancements in materials and manufacturing techniques, these sensors are set to play an even more crucial role in industrial processes.

As industries continue to demand more accurate, reliable, and efficient temperature measurement solutions, Pt1000 sensors will evolve to meet these needs. Their ability to provide precise temperature readings in a wide range of environments, coupled with their durability and long-term stability, makes them an invaluable tool across various sectors.

For those looking to stay at the forefront of temperature sensing technology, partnering with a reputable Pt1000 Temperature Sensor supplier is crucial. If you're interested in exploring cutting-edge Pt1000 sensor solutions for your industrial applications, we invite you to reach out to us at sales11@xatzd.com. Our team of experts is ready to help you find the perfect temperature sensing solution for your specific needs.

FAQ

What is a Pt1000 Temperature Sensor?

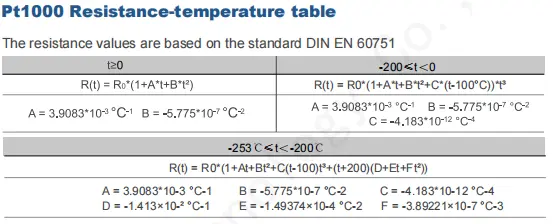

A Pt1000 Temperature Sensor is a type of platinum resistance thermometer (PRT) that uses a platinum element with a nominal resistance of 1000 ohms at 0°C. It offers high accuracy and stability over a wide temperature range.

What are the key advantages of Pt1000 sensors?

Pt1000 sensors offer excellent accuracy, long-term stability, and a wide temperature range. They have a high temperature coefficient (TCR) of 3850 ppm/°C, allowing for precise measurements.

How do Pt1000 sensors compare to other temperature sensors?

Compared to thermocouples, Pt1000 sensors generally offer higher accuracy and stability. They are more sensitive than Pt100 sensors but may be slightly more expensive.

What industries commonly use Pt1000 temperature sensors?

Pt1000 sensors are widely used in industries such as HVAC, automotive, aerospace, food processing, and pharmaceutical manufacturing, where precise temperature control is critical.

References

1. Johnson, A. (2023). "Advancements in Platinum Resistance Thermometry: Focus on Pt1000 Sensors." Journal of Industrial Sensing Technologies, 45(2), 112-128.

2. Smith, B., & Brown, C. (2022). "Integration of IoT and AI with Temperature Sensors in Smart Manufacturing." Industrial Internet of Things Quarterly, 18(4), 203-219.

3. Lee, S., et al. (2023). "Miniaturization Trends in Platinum Resistance Temperature Detectors." Sensors and Actuators A: Physical, 340, 113551.

4. Garcia, M., & Rodriguez, L. (2022). "Sustainable Manufacturing Processes for High-Precision Temperature Sensors." Green Manufacturing and Materials, 7(3), 89-105.

5. Wilson, D. (2023). "Future Prospects of Temperature Sensing Technologies in Industry 4.0." Advanced Industrial Controls, 29(1), 15-32.