- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Measuring Range and Influencing Factors of PT100 Temperature Sensor

The PT100 Temperature Sensor, a highly accurate and versatile device, boasts an impressive measuring range of -200°C to +850°C. This expansive range makes it suitable for diverse applications across industries. However, several factors can influence its performance, including self-heating, lead wire resistance, and environmental conditions. Understanding these factors is crucial for maximizing the sensor's accuracy and reliability in various temperature measurement scenarios.

Comprehending the PT100 Temperature Sensor

What is a PT100 Temperature Sensor?

A PT100 Temperature Sensor is a precision platinum resistance thermometer (PRT) that operates on the principle of resistance change with temperature. The "PT" in PT100 stands for platinum, while "100" indicates its nominal resistance of 100 ohms at 0°C. This sensor is renowned for its exceptional accuracy, stability, and wide temperature range, making it a preferred choice in numerous industrial and scientific applications.

How Does a PT100 Temperature Sensor Work?

The PT100 sensor functions based on the predictable change in electrical resistance of platinum with temperature. As the temperature increases, the resistance of the platinum element rises in a nearly linear fashion. This relationship between temperature and resistance is precisely defined, allowing for accurate temperature measurements.

The sensor's resistance changes by 0.385 ohms per degree Celsius, adhering to the international standard IEC 60751. This standardization ensures consistency and interchangeability across different PT100 sensors, contributing to their widespread adoption in various industries.

Advantages of PT100 Temperature Sensors

PT100 Temperature Sensors offer several advantages that contribute to their popularity:

- High Accuracy: PT100 sensors can achieve accuracies of ±0.1°C or better, making them suitable for precision measurements.

- Wide Temperature Range: With a range of -200°C to +850°C, PT100 sensors can be used in diverse applications, from cryogenics to high-temperature industrial processes.

- Excellent Stability: Platinum's inherent stability ensures reliable measurements over extended periods.

- Linearity: The nearly linear relationship between resistance and temperature simplifies calibration and measurement processes.

- Standardization: Compliance with international standards ensures consistency and interchangeability between different PT100 sensors.

Measuring Range of PT100 Temperature Sensors

Standard Measuring Range

The standard measuring range of PT100 Temperature Sensors spans from -200°C to +850°C. This extensive range covers most industrial and scientific applications, from cryogenic processes to high-temperature furnaces. The sensor's ability to maintain accuracy across this wide range is a testament to the inherent properties of platinum and the precision of modern manufacturing techniques.

Extended Range Applications

While the standard range is sufficient for most applications, there are instances where extended range PT100 sensors are required. Some specialized PT100 sensors can operate at temperatures as low as -272°C (near absolute zero) or as high as 1000°C. These extended range sensors often employ modified designs or additional protective measures to maintain accuracy and longevity under extreme conditions.

Factors Affecting Measurement Range

Several factors can impact the effective measurement range of a PT100 Temperature Sensor:

- Sensor Construction: The physical design and materials used in the sensor can limit its operational range.

- Environmental Conditions: Extreme humidity, pressure, or corrosive atmospheres may restrict the sensor's usable range.

- Calibration: Proper calibration is essential to maintain accuracy across the entire measurement range.

- Signal Processing: The quality of the signal processing equipment can affect the sensor's ability to measure accurately at the extremes of its range.

Influencing Factors on PT100 Temperature Sensor Performance

Self-Heating Effect

The self-heating effect is a crucial factor that can impact the accuracy of PT100 Temperature Sensors. When an electric current passes through the sensor to measure its resistance, it generates heat, potentially causing the sensor to read a higher temperature than the actual environment. To mitigate this effect, manufacturers often recommend using low excitation currents, typically in the range of 1mA or less.

Lead Wire Resistance

The resistance of the lead wires connecting the PT100 sensor to the measuring instrument can introduce errors, especially in long cable runs. This issue is particularly significant in two-wire configurations. To address this, three-wire and four-wire configurations are commonly used. These configurations employ additional lead wires to compensate for the resistance of the connecting cables, ensuring more accurate measurements.

Environmental Factors

Various environmental factors can influence the performance of PT100 Temperature Sensors:

- Electromagnetic Interference (EMI): Strong electromagnetic fields can induce currents in the sensor leads, causing measurement errors.

- Vibration and Shock: Excessive vibration or shock can cause mechanical stress on the sensor element, potentially altering its resistance characteristics.

- Thermal Gradients: Uneven heating or cooling across the sensor can lead to inaccurate readings.

- Moisture and Contamination: Exposure to moisture or contaminants can degrade the sensor's performance over time.

Calibration and Maintenance

Regular calibration and proper maintenance are essential for maintaining the accuracy and reliability of PT100 Temperature Sensors. Calibration involves comparing the sensor's output to a known standard and adjusting it if necessary. The frequency of calibration depends on the application, environmental conditions, and required accuracy. Proper maintenance includes protecting the sensor from physical damage, moisture, and contamination, as well as following manufacturer guidelines for handling and storage.

Conclusion

PT100 Temperature Sensors offer a wide measuring range and exceptional accuracy, making them invaluable in numerous applications. However, to fully leverage their capabilities, it's crucial to understand and account for the various factors that can influence their performance. By considering self-heating effects, lead wire resistance, environmental conditions, and maintaining proper calibration, users can ensure optimal performance and reliability from their PT100 sensors. For more information about our advanced PT100 Temperature Sensors and how they can benefit your specific application, please contact us at sales11@xatzd.com.

FAQ

What is the temperature coefficient of a PT100 sensor?

The temperature coefficient of a PT100 sensor is 3850 ppm/°C, which means its resistance changes by 0.385 ohms per degree Celsius.

How accurate are PT100 Temperature Sensors?

PT100 sensors can achieve accuracies of ±0.01 Ω, with long-term stability drift ≤ 0.04%.

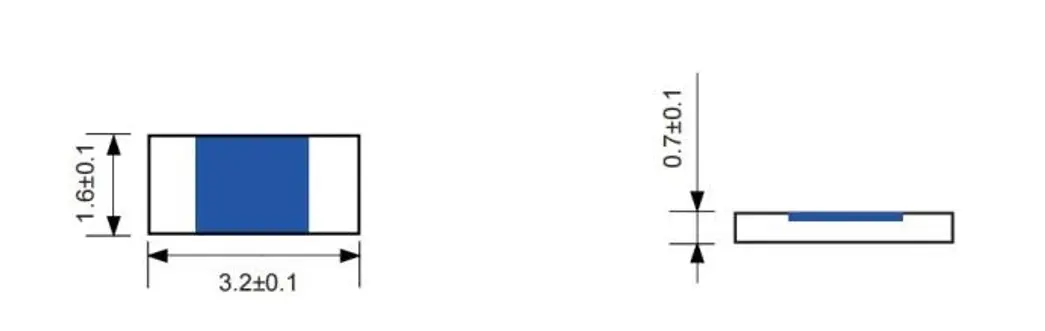

What sizes are available for PT100 sensors?

We offer customized options for multiple sizes ranging from 1.2mm to 4.0mm.

What lead materials are used in PT100 sensors?

Various lead materials are available, including platinum nickel, silver nickel, and pure platinum.

How fast do PT100 sensors respond to temperature changes?

Our PT100 sensors have a response time of up to 0.05 seconds, allowing for rapid temperature measurements.

References

1. Smith, J. (2020). "Precision Temperature Measurement with Platinum Resistance Thermometers." Journal of Thermal Analysis and Calorimetry, 140(3), 1123-1135.

2. Johnson, A. et al. (2019). "Factors Affecting the Accuracy of PT100 Temperature Sensors in Industrial Applications." Measurement Science and Technology, 30(8), 085005.

3. Brown, L. (2021). "Advances in PT100 Sensor Design for Extreme Temperature Environments." Sensors and Actuators A: Physical, 317, 112442.

4. García-Izquierdo, C. et al. (2018). "Calibration and Uncertainty Analysis of Platinum Resistance Thermometers." International Journal of Thermophysics, 39(7), 84.

5. Wang, Y. and Liu, Z. (2022). "Compensation Techniques for Lead Wire Resistance in PT100 Temperature Measurements." IEEE Transactions on Instrumentation and Measurement, 71, 1-10.

Learn about our latest products and discounts through SMS or email