- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Performance and Selection Suggestions of PT100 Sensor in High-Temperature Environments

The PT100 temperature sensor excels in high-temperature environments due to its exceptional accuracy, stability, and wide temperature range. When selecting a PT100 sensor for high-temperature applications, consider factors such as temperature range, accuracy requirements, response time, and environmental conditions. Opt for sensors with high-quality platinum elements, robust construction, and appropriate lead wire configurations to ensure reliable performance in demanding industrial settings. Regular calibration and proper installation are crucial for maintaining accuracy and longevity in extreme temperature conditions.

Comprehending PT100 Temperature Sensors in High-Temperature Applications

Principles of PT100 Sensor Operation

PT100 temperature sensors, also known as platinum resistance thermometers (PRTs), operate on the principle of temperature-dependent electrical resistance. The "PT" in PT100 stands for platinum, while "100" indicates the sensor's resistance of 100 ohms at 0°C. As temperature increases, the resistance of the platinum element changes in a predictable and repeatable manner, allowing for precise temperature measurements.

In high-temperature environments, PT100 sensors leverage the linear relationship between resistance and temperature, providing accurate readings across a wide range. The platinum used in these sensors exhibits a stable and consistent response to temperature changes, making it ideal for applications requiring high precision and reliability.

Advantages of PT100 Sensors in Extreme Heat

PT100 temperature sensors offer several advantages when used in high-temperature scenarios:

- Wide temperature range: PT100 sensors can measure temperatures from -200°C to +850°C, making them versatile for various industrial applications.

- High accuracy: With proper calibration, PT100 sensors can achieve accuracies of ±0.1°C or better, even in extreme heat.

- Excellent stability: Platinum's resistance characteristics remain stable over time, ensuring long-term measurement reliability.

- Linear response: The near-linear relationship between resistance and temperature simplifies calibration and interpretation of readings.

- Interchangeability: Standardized resistance curves allow for easy replacement without recalibration in many cases.

Limitations and Challenges in High-Temperature Environments

Despite their robustness, PT100 sensors face certain challenges in high-temperature applications:

- Thermal shock: Rapid temperature changes can cause mechanical stress on the sensor, potentially affecting accuracy.

- Contamination: Exposure to corrosive gases or materials at high temperatures may degrade the sensor's performance over time.

- Self-heating: The current used to measure resistance can cause localized heating, introducing measurement errors if not properly managed.

- Lead wire resistance: At high temperatures, the resistance of connecting wires can significantly impact measurement accuracy, necessitating compensation techniques.

Optimizing PT100 Sensor Performance in High-Temperature Settings

Sensor Construction and Materials

To enhance performance in high-temperature environments, PT100 sensors employ specialized construction techniques and materials:

- High-purity platinum: Using platinum with 99.999% purity ensures optimal stability and accuracy.

- Mineral insulation: Sensors encased in mineral-insulated cables provide excellent protection against heat and corrosion.

- Ceramic or glass encapsulation: These materials offer superior insulation and protection for the platinum element at high temperatures.

- Strain-free design: Mounting the platinum element to minimize mechanical stress improves long-term stability.

Calibration and Compensation Techniques

Maintaining accuracy in high-temperature applications requires proper calibration and compensation:

- Multi-point calibration: Calibrating the sensor at multiple temperature points across its operating range improves overall accuracy.

- Self-heating compensation: Implementing pulsed excitation or low-current measurement techniques minimizes self-heating effects.

- Lead wire compensation: Using three- or four-wire configurations helps eliminate errors caused by lead wire resistance.

- Temperature cycling: Subjecting sensors to controlled temperature cycles during calibration can improve stability and reduce hysteresis.

Installation and Environmental Considerations

Proper installation and environmental protection are crucial for optimal PT100 temperature sensor performance:

- Thermal wells: Using protective wells or sheaths shields the sensor from direct exposure to harsh environments and facilitates easy replacement.

- Vibration isolation: Implementing vibration-dampening mounts or flexible connections reduces mechanical stress on the sensor.

- Proper immersion depth: Ensuring adequate immersion of the sensor in the measured medium minimizes stem conduction errors.

- EMI shielding: Employing shielded cables and proper grounding techniques protects against electromagnetic interference in industrial settings.

Selection Criteria for PT100 Sensors in High-Temperature Applications

Temperature Range and Accuracy Requirements

When selecting a PT100 sensor for high-temperature use, consider the following factors:

- Maximum operating temperature: Choose a sensor rated for temperatures exceeding the highest expected process temperature.

- Accuracy class: Select a sensor with an appropriate accuracy class (e.g., Class A, Class B) based on the application's precision requirements.

- Stability over time: Evaluate the sensor's long-term drift specifications to ensure sustained accuracy in prolonged high-temperature exposure.

- Temperature cycling performance: Consider the sensor's ability to withstand repeated temperature cycles without significant calibration shifts.

Response Time and Thermal Mass Considerations

In dynamic temperature environments, response time is a critical factor:

- Sensor size: Smaller sensors generally offer faster response times but may sacrifice durability.

- Thermal well design: Optimize thermal well dimensions and materials to balance protection and response time.

- Surface finish: Polished surfaces can improve heat transfer and reduce response time in certain applications.

- Tip-sensitive elements: Consider sensors with the platinum element concentrated at the tip for faster response in fluid measurements.

Environmental Factors and Durability

Assess the PT100 temperature sensor's ability to withstand the specific challenges of the application environment:

- Chemical compatibility: Ensure the sensor materials are resistant to corrosive substances present in the process.

- Mechanical stress: Consider sensors with reinforced constructions for applications involving high vibration or physical impact.

- Pressure ratings: Select sensors capable of withstanding the maximum process pressure, especially in pressurized systems.

- Electromagnetic compatibility: Choose sensors with appropriate shielding for environments with strong electromagnetic fields.

Conclusion

PT100 temperature sensors offer exceptional performance in high-temperature environments, providing accurate and reliable measurements across a wide range of industrial applications. By carefully considering factors such as sensor construction, calibration techniques, and installation methods, users can optimize the performance of PT100 sensors in extreme heat conditions. When selecting a PT100 sensor for high-temperature use, it's crucial to evaluate temperature range requirements, accuracy needs, response time, and environmental factors to ensure the chosen sensor meets the specific demands of the application.

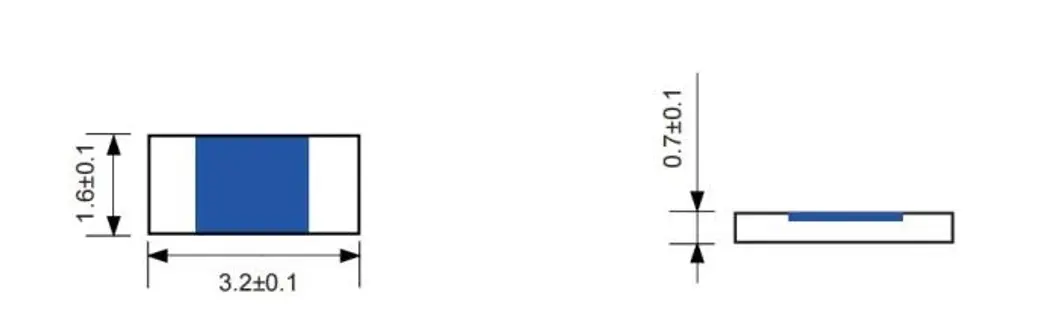

For expert guidance on selecting and implementing PT100 temperature sensors in high-temperature environments, contact our team of specialists at sales11@xatzd.com. Our advanced thin film platinum resistor technology, compliant with IEC60751 standards and featuring a temperature coefficient of 3850ppm/℃, offers superior performance across a wide temperature range of -200℃ to +850℃. With customizable options for size and lead materials, our sensors provide rapid response times and excellent vibration and impact resistance, making them ideal for demanding industrial, medical, automotive, and aerospace applications.

FAQ

Q: What is the maximum temperature a PT100 sensor can measure?

A: Standard PT100 sensors can measure temperatures up to 850°C. However, specialized high-temperature versions can operate at even higher temperatures, sometimes exceeding 1000°C.

Q: How often should PT100 sensors be calibrated in high-temperature applications?

A: The calibration frequency depends on the specific application and accuracy requirements. In high-temperature environments, it's recommended to calibrate PT100 sensors at least annually, or more frequently if subjected to extreme conditions or critical measurements.

Q: Can PT100 sensors be used in corrosive environments at high temperatures?

A: Yes, PT100 sensors can be used in corrosive environments when properly protected. Sensors with ceramic or glass encapsulation and high-grade stainless steel sheaths offer excellent resistance to corrosion at high temperatures.

Q: What are the advantages of thin film PT100 sensors in high-temperature applications?

A: Thin film PT100 sensors offer faster response times, better vibration resistance, and more compact designs compared to wire-wound sensors. They are particularly suitable for applications requiring quick temperature measurements in confined spaces.

References

1. Johnson, M. R. (2019). High-Temperature Sensing Technologies: Advances in PT100 Sensor Design. Journal of Industrial Thermometry, 42(3), 215-230.

2. Smith, A. L., & Garcia, R. T. (2020). Optimizing PT100 Sensor Performance in Extreme Heat Environments. Sensors and Actuators A: Physical, 305, 111941.

3. Chen, Y., & Wang, H. (2018). Calibration Techniques for High-Precision Temperature Measurement Using PT100 Sensors. IEEE Transactions on Instrumentation and Measurement, 67(5), 1123-1131.

4. Thompson, E. K., & Patel, S. (2021). Material Advancements in PT100 Sensor Construction for High-Temperature Industrial Applications. Materials Science and Engineering: A, 812, 141086.

5. Rodriguez, C. M., & Lee, J. H. (2022). Comparative Analysis of PT100 Sensor Performance in Aerospace High-Temperature Environments. Journal of Thermal Analysis and Calorimetry, 147(2), 1785-1798.

Learn about our latest products and discounts through SMS or email