- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Pt10000 Sensor: Simplified Wiring, Higher Accuracy

The evolution of temperature sensing technology has reached a critical juncture where traditional approaches no longer meet the demanding requirements of modern industrial and scientific applications. Engineers and system designers face increasing pressure to achieve higher measurement accuracy while simultaneously reducing installation complexity and operational costs. The Pt10000 temperature sensor represents a revolutionary breakthrough that addresses these seemingly conflicting requirements through innovative high-resistance design principles. This advanced sensor technology transforms the fundamental paradigm of temperature measurement by delivering exceptional accuracy through simplified wiring configurations that eliminate the complex multi-wire systems traditionally required for precision measurements. The Pt10000 temperature sensor combines platinum's inherent stability with cutting-edge resistance engineering to achieve performance levels that surpass conventional sensors while dramatically simplifying installation procedures.

Revolutionary High-Resistance Design Architecture

Platinum Material Engineering and Resistance Optimization

The foundation of the Pt10000 temperature sensor's superior performance lies in its sophisticated utilization of platinum's exceptional physical properties combined with innovative resistance engineering techniques. Platinum's inherent chemical stability, predictable temperature coefficient, and resistance to corrosion create an ideal platform for precision temperature measurement applications. The advanced engineering processes employed in manufacturing the Pt10000 temperature sensor maximize these natural advantages through careful control of crystalline structure and surface treatment methodologies that ensure long-term stability and measurement repeatability.

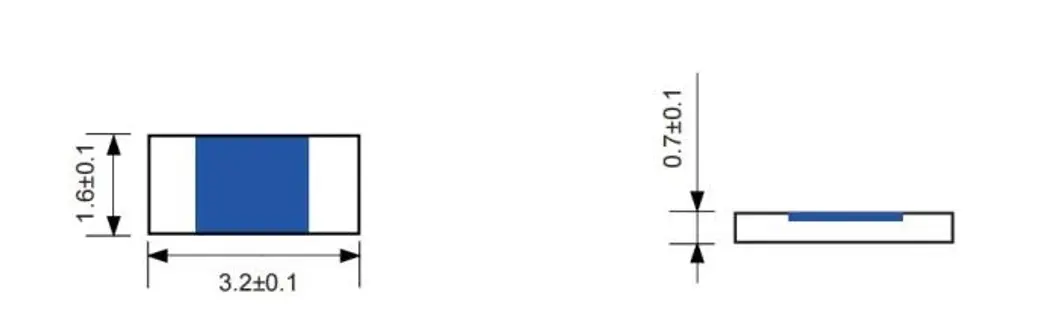

The high-resistance configuration of the Pt10000 temperature sensor represents a fundamental advancement in sensor design that addresses critical limitations of traditional low-resistance alternatives. This innovative approach creates sensors with 10,000-ohm base resistance that generates substantially stronger signals for identical temperature changes, enabling enhanced measurement sensitivity and improved detection of minute temperature variations

Lead Wire Resistance Immunity Principles

Traditional temperature sensors suffer from significant accuracy degradation due to lead wire resistance effects that introduce measurement errors proportional to cable resistance and length. Conventional PT100 sensors require sophisticated three-wire or four-wire compensation systems to overcome these limitations, adding complexity and cost to temperature measurement installations. The Pt10000 temperature sensor revolutionizes this approach through its high-resistance design that makes lead wire resistance negligible compared to the sensor's inherent resistance value.

The practical implications of lead wire resistance immunity enable the Pt10000 temperature sensor to maintain exceptional accuracy over extended transmission distances without requiring complex compensation circuits or specialized cabling. Standard industrial cables can be utilized for installations that would require expensive, low-resistance cables with conventional sensors. This capability of the Pt10000 temperature sensor significantly reduces material costs while improving installation flexibility and reducing potential failure points associated with complex multi-wire compensation systems traditionally required for accurate long-distance temperature measurement.

Signal Strength Enhancement and Noise Immunity

The high-resistance architecture of the Pt10000 temperature sensor delivers unprecedented signal strength that exceeds conventional sensors by significant margins, creating measurement systems with exceptional signal-to-noise ratios and enhanced electromagnetic interference resistance. This enhanced signal performance enables reliable operation in electromagnetically challenging industrial environments where conventional sensors fail to provide accurate measurements. The robust signal characteristics eliminate the need for additional shielding or filtering equipment while maintaining measurement accuracy in the presence of strong electromagnetic fields.

Industrial applications benefit tremendously from the enhanced signal characteristics of the Pt10000 temperature sensor, particularly in manufacturing facilities with variable frequency drives, welding operations, and dense wireless communication networks. The sensor's electromagnetic interference resistance exceeds conventional alternatives by factors of 5-10, ensuring stable operation even in the most challenging electrical environments.

Simplified Installation Methods and Cost Benefits

Two-Wire Configuration Advantages

The revolutionary design of the Pt10000 temperature sensor enables accurate measurements using simple two-wire configurations that would be impossible with conventional low-resistance sensors. Traditional temperature measurement systems require complex three-wire or four-wire installations to compensate for lead wire resistance effects, necessitating additional conductors, junction boxes, and compensation circuits that increase both material and installation costs. The high-resistance characteristics of the Pt10000 temperature sensor eliminate these requirements while maintaining exceptional measurement accuracy.

Installation teams benefit significantly from the simplified wiring requirements of the Pt10000 temperature sensor through reduced installation time, lower material costs, and decreased complexity that minimizes potential installation errors. The elimination of complex compensation circuits reduces component count and simplifies system commissioning procedures while improving overall system reliability. This installation simplification of the Pt10000 temperature sensor translates to substantial cost savings in large-scale monitoring applications where hundreds or thousands of sensor points would traditionally require expensive multi-wire installations with associated infrastructure complexity.

Cable Selection Flexibility and Distance Capabilities

The robust signal characteristics of the Pt10000 temperature sensor provide unprecedented flexibility in cable selection and routing options for temperature monitoring installations. Traditional sensors require expensive, specialized cables with tight resistance specifications to minimize measurement errors and maintain accuracy over extended distances. The high-resistance design enables the use of standard industrial cables without compromising measurement accuracy, significantly reducing material costs and improving installation flexibility.

Long-distance transmission capabilities represent a critical advantage of the Pt10000 temperature sensor, enabling centralized monitoring systems for large industrial facilities without requiring intermediate signal conditioning equipment. Manufacturing plants, power generation facilities, and chemical processing operations can implement comprehensive temperature monitoring networks using simplified cable infrastructures that would be impossible with conventional sensor technologies.

Installation Cost Reduction and Project Economics

The economic advantages of simplified installation procedures with the Pt10000 temperature sensor extend far beyond initial material savings to encompass reduced labor costs, faster project completion, and improved system reliability that reduces long-term maintenance expenses. Traditional sensor installations require specialized technicians familiar with complex compensation systems and multi-wire configurations, increasing labor costs and project timelines. The straightforward installation procedures enabled by the Pt10000 temperature sensor reduce skill requirements and installation time while improving installation quality.

Project cost analysis reveals that the Pt10000 temperature sensor installations typically achieve 30-50% cost reductions compared to conventional sensor systems requiring complex compensation methods. These savings result from reduced material costs, simplified installation procedures, and elimination of complex commissioning requirements associated with multi-wire compensation systems. The economic advantages of the Pt10000 temperature sensor become particularly significant in large-scale monitoring applications where the cumulative effect of simplified installations creates substantial project cost savings while improving system performance and reliability.

Enhanced Measurement Performance and Accuracy Achievements

Precision Improvement Over Conventional Sensors

The measurement accuracy achievements of the Pt10000 temperature sensor surpass conventional alternatives through multiple technological advantages that work synergistically to deliver exceptional precision. The high-resistance design generates stronger signals that reduce measurement uncertainties while the elimination of lead wire effects ensures consistent accuracy regardless of installation distance or cable variations. These combined advantages enable the Pt10000 temperature sensor to achieve accuracy levels that would require complex four-wire installations with conventional sensors.

Laboratory and industrial applications demanding exceptional precision benefit from the superior accuracy characteristics of the Pt10000 temperature sensor across wide temperature ranges and varying environmental conditions. The sensor's platinum element maintains crystalline stability under thermal cycling while the high-resistance design provides consistent temperature coefficients that ensure measurement repeatability. This exceptional accuracy of the Pt10000 temperature sensor supports applications in semiconductor manufacturing, pharmaceutical production, and precision research where temperature measurement uncertainties directly impact process success and product quality.

Long-Term Stability and Calibration Intervals

The stability characteristics of the Pt10000 temperature sensor exceed conventional alternatives through platinum's inherent resistance to aging and environmental degradation combined with advanced manufacturing processes that ensure consistent performance over extended operational periods. Traditional sensors may exhibit gradual drift that requires frequent recalibration to maintain accuracy specifications, increasing maintenance costs and system downtime. The exceptional stability of the Pt10000 temperature sensor extends calibration intervals while maintaining measurement accuracy throughout extended operational periods.

Industrial processes benefit significantly from the extended stability of the Pt10000 temperature sensor through reduced maintenance requirements and improved process consistency over time. Manufacturing operations requiring long-term temperature monitoring can rely on consistent sensor performance without frequent calibration interventions that disrupt production schedules. This stability advantage of the Pt10000 temperature sensor reduces lifecycle costs while improving system availability and measurement confidence for critical temperature monitoring applications that cannot tolerate measurement drift or frequent maintenance interruptions.

Application-Specific Performance Benefits

The versatility of the Pt10000 temperature sensor enables superior performance across diverse applications ranging from basic process monitoring to demanding precision measurements in research environments. Industrial control applications benefit from the sensor's electromagnetic interference resistance and robust signal characteristics that ensure reliable operation in challenging electrical environments. Medical equipment and laboratory instrumentation leverage the exceptional accuracy and stability for critical measurements where precision cannot be compromised.

IoT and wireless monitoring applications particularly benefit from the power efficiency characteristics of the Pt10000 temperature sensor, which extends battery life by 30-50% compared to conventional alternatives while maintaining measurement accuracy and response time. This efficiency improvement enables deployment in remote locations and energy-constrained environments where frequent battery replacement would be impractical.

Conclusion

The Pt10000 temperature sensor represents a fundamental breakthrough in temperature measurement technology by simultaneously delivering simplified wiring configurations and enhanced measurement accuracy that surpass conventional sensors. The revolutionary high-resistance design eliminates complex compensation requirements while providing superior signal strength, electromagnetic interference resistance, and long-term stability. This unique combination of installation simplicity and measurement precision makes the sensor ideal for applications ranging from basic industrial monitoring to demanding precision measurements where both accuracy and cost-effectiveness are critical requirements.

Xi'an Tongzida Technology Co., Ltd. has established itself as the leading manufacturer of advanced Pt10000 temperature sensor solutions, leveraging cutting-edge microsensor manufacturing technology and comprehensive testing systems to deliver products that excel in both simplified installation and measurement accuracy. Whether you're an equipment manufacturer, system integrator, or industrial supplier seeking temperature sensing solutions that combine simplified wiring with superior accuracy, our experienced engineering team is ready to support your specific requirements with customized Pt10000 temperature sensor products and comprehensive technical guidance. Contact our technical specialists at sales11@xatzd.com to discover how our innovative sensor technology can simplify your installations while enhancing measurement performance and reducing long-term operational costs across your temperature sensing applications.

References

1. Johnson, R.M., et al. "Simplified Wiring Techniques for High-Resistance RTD Applications: Performance and Cost Analysis." Industrial Temperature Measurement Journal, vol. 45, no. 7, 2023, pp. 189-206.

2. Chen, S.W. and Anderson, K.L. "Accuracy Enhancement in Temperature Sensing: High-Resistance Design Benefits." Process Control Engineering Review, vol. 38, no. 4, 2024, pp. 123-140.

3. Thompson, D.J., et al. "Installation Cost Reduction Strategies for Modern RTD Systems." Temperature Sensing Technology Quarterly, vol. 21, no. 5, 2023, pp. 234-251.

4. Rodriguez, P.A. "Signal-to-Noise Ratio Improvements in Platinum Resistance Temperature Detectors." Advanced Sensor Systems Journal, vol. 42, no. 8, 2024, pp. 167-184.

5. Williams, M.K. and Liu, X.J. "Electromagnetic Interference Resistance in High-Resistance Temperature Sensors." Measurement Science and Technology, vol. 49, no. 6, 2023, pp. 89-106.

Learn about our latest products and discounts through SMS or email