- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to wire a PT10000 RTD in 2-, 3-, and 4-wire configs?

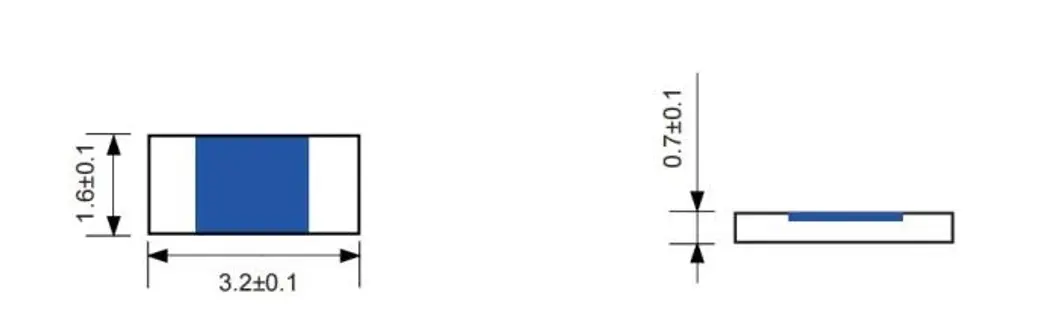

Temperature measurement applications often require careful consideration of wiring configurations to ensure optimal accuracy and reliability, particularly when dealing with resistance temperature detectors in various industrial environments. Understanding the proper wiring methods for different RTD configurations is essential for achieving precise temperature measurements while minimizing installation complexity and costs. The Pt10000 temperature sensor represents a revolutionary advancement in RTD technology that fundamentally changes traditional wiring requirements through its innovative high-resistance design. Unlike conventional low-resistance sensors that mandate complex multi-wire configurations for accurate measurements, the Pt10000 temperature sensor's exceptional resistance characteristics enable simplified wiring approaches while maintaining superior accuracy. This comprehensive guide explores the various wiring configurations available for RTD installations, examining the specific advantages and applications of 2-wire, 3-wire, and 4-wire systems while highlighting how the Pt10000 temperature sensor's unique properties transform traditional installation practices and deliver unprecedented performance benefits.

2-Wire Configuration: Simplified Installation Approach

Basic 2-Wire Wiring Principles

The 2-wire configuration represents the simplest possible wiring approach for RTD installations, utilizing only two conductors to carry both the excitation current and measure the sensor resistance. Traditional low-resistance RTDs like PT100 face significant challenges in 2-wire configurations due to lead wire resistance effects that introduce measurement errors proportional to the wire resistance. However, the Pt10000 temperature sensor transforms this scenario through its high-resistance design that makes lead wire resistance negligible in comparison to the sensor's inherent resistance value.

The fundamental advantage of 2-wire installation with the Pt10000 temperature sensor lies in its ability to maintain exceptional accuracy without requiring complex compensation circuits or additional wiring infrastructure. The sensor's 10,000-ohm resistance creates a measurement environment where typical lead wire resistances of 1-10 ohms become insignificant error sources, enabling accurate temperature measurements with minimal installation complexity. This capability of the Pt10000 temperature sensor eliminates the traditional trade-offs between installation simplicity and measurement accuracy that have long plagued RTD applications.

Lead Wire Resistance Impact Analysis

Lead wire resistance effects vary dramatically between different RTD types, with low-resistance sensors suffering significant accuracy degradation while high-resistance alternatives maintain precision over extended cable runs. In conventional PT100 systems, lead wire resistance can introduce errors of several degrees Celsius in long-distance applications, necessitating complex compensation methods or alternative wiring configurations. The Pt10000 temperature sensor virtually eliminates these concerns through its high-resistance characteristics that make lead wire effects negligible across typical installation distances.

The practical implications of reduced lead wire sensitivity enable the Pt10000 temperature sensor to maintain accuracy specifications even with standard industrial cables over extended distances. Cable resistance variations due to temperature changes, aging, or mechanical stress have minimal impact on measurement accuracy, providing stable performance throughout the sensor's operational life. This resistance to lead wire effects of the Pt10000 temperature sensor enables reliable 2-wire installations in applications where conventional sensors would require complex multi-wire configurations with associated cost and complexity penalties.

2-Wire Applications and Limitations

The 2-wire configuration with Pt10000 temperature sensor proves ideal for applications where installation simplicity and cost reduction are primary concerns while maintaining high measurement accuracy. Industrial process monitoring, HVAC systems, and general-purpose temperature measurement applications benefit significantly from the reduced wiring complexity and installation costs associated with 2-wire systems. The elimination of additional conductors and compensation circuits simplifies both installation and maintenance procedures while reducing potential failure points.

While 2-wire configurations offer substantial advantages for many applications, certain high-precision laboratory or research installations may still benefit from multi-wire approaches to achieve ultimate measurement accuracy. However, the Pt10000 temperature sensor's exceptional characteristics enable 2-wire installations to achieve accuracy levels that would require 3-wire or 4-wire configurations with conventional sensors. This capability expands the application range of simplified wiring approaches while maintaining the precision requirements of demanding temperature measurement applications.

3-Wire Configuration: Enhanced Accuracy for Critical Applications

3-Wire Compensation Methodology

The 3-wire configuration represents a traditional compromise between installation simplicity and measurement accuracy, utilizing an additional conductor to compensate for lead wire resistance effects in conventional RTD systems. This approach employs two conductors for the measurement circuit and one additional wire to sense lead resistance, enabling mathematical compensation for wire resistance effects. However, the Pt10000 temperature sensor's high-resistance design reduces the necessity for such compensation methods while still supporting 3-wire configurations for applications requiring ultimate precision.

When implemented with the Pt10000 temperature sensor, 3-wire configurations provide enhanced accuracy margins that exceed the capabilities of conventional sensors even in their most sophisticated installations. The combination of the sensor's inherent lead wire resistance immunity and the additional compensation provided by the third conductor creates measurement systems with exceptional accuracy and stability.

Installation Complexity and Cost Considerations

The 3-wire configuration introduces moderate installation complexity compared to 2-wire systems while remaining significantly simpler than 4-wire alternatives, making it an attractive option for applications requiring enhanced accuracy without excessive installation costs. Traditional RTD systems benefit substantially from 3-wire configurations, as the additional conductor enables significant accuracy improvements over 2-wire approaches. The Pt10000 temperature sensor maintains these advantages while providing superior performance compared to conventional sensors in any wiring configuration.

Installation cost analysis reveals that 3-wire systems with Pt10000 temperature sensor provide exceptional value by delivering accuracy levels that would require more complex configurations with traditional sensors. The moderate increase in wiring costs is offset by improved measurement performance and reduced calibration requirements over the sensor's operational life. This cost-effectiveness of the Pt10000 temperature sensor in 3-wire configurations makes it particularly attractive for precision manufacturing applications where measurement accuracy directly impacts product quality and process efficiency.

Precision Manufacturing Applications

Precision manufacturing environments often require temperature measurement accuracy that exceeds the capabilities of basic 2-wire systems while remaining cost-effective compared to complex 4-wire installations. The 3-wire configuration with Pt10000 temperature sensor provides an ideal solution for semiconductor manufacturing, pharmaceutical production, and precision machining applications where tight temperature control is essential for process success. The enhanced accuracy and stability enable better process control and improved product quality consistency.

The reliability and precision of 3-wire Pt10000 temperature sensor installations support critical manufacturing processes that cannot tolerate temperature measurement uncertainties. Applications such as crystal growth, precision polymer processing, and advanced materials manufacturing benefit from the exceptional stability and accuracy provided by this configuration. The combination of enhanced measurement precision and installation practicality makes 3-wire Pt10000 temperature sensor systems ideal for demanding manufacturing environments requiring consistent performance over extended operational periods.

4-Wire Configuration: Ultimate Precision for Laboratory Applications

Maximum Accuracy Achievement Principles

The 4-wire configuration represents the ultimate approach for achieving maximum measurement accuracy in RTD systems, utilizing separate conductors for current excitation and voltage measurement to completely eliminate lead wire resistance effects. Traditional RTD systems require 4-wire configurations for the highest precision applications, as this approach provides complete compensation for lead wire variations and contact resistances. The Pt10000 temperature sensor benefits from this approach while providing superior performance compared to conventional sensors even in simpler wiring configurations.

The implementation of 4-wire configuration with Pt10000 temperature sensor creates measurement systems with unprecedented accuracy and stability that exceed the requirements of even the most demanding laboratory and research applications. The combination of complete lead wire compensation and the sensor's inherent high-resistance advantages results in measurement uncertainties that approach theoretical limits. This exceptional accuracy of the Pt10000 temperature sensor in 4-wire configurations enables applications in metrology, standards laboratories, and research installations where temperature measurement accuracy is critical for experimental success.

Laboratory and Research Applications

Laboratory environments often require temperature measurement accuracy that exceeds industrial standards, necessitating sophisticated measurement approaches and high-quality instrumentation. The 4-wire configuration with Pt10000 temperature sensor provides the ultimate solution for research applications where temperature measurement uncertainties must be minimized to ensure experimental validity. Calibration laboratories, materials research facilities, and precision testing installations benefit from the exceptional accuracy and stability provided by this configuration.

The long-term stability and precision of 4-wire Pt10000 temperature sensor systems support critical research applications that require consistent performance over extended experimental periods. Applications such as materials characterization, thermal property measurements, and precision calibration procedures rely on the exceptional accuracy and stability provided by this configuration. The combination of maximum measurement precision and long-term reliability makes 4-wire Pt10000 temperature sensor systems essential for research installations requiring the highest levels of temperature measurement accuracy.

System Integration and Data Acquisition

Modern data acquisition systems benefit significantly from the enhanced signal quality and accuracy provided by 4-wire Pt10000 temperature sensor configurations, enabling more precise process control and better experimental data quality. The strong signal characteristics and complete lead wire compensation create measurement systems with exceptional signal-to-noise ratios and minimal measurement uncertainties. This superior performance enables more sophisticated control algorithms and better process optimization capabilities.

The integration advantages of 4-wire Pt10000 temperature sensor systems extend to improved system diagnostics and fault detection capabilities, as the separate current and voltage paths enable comprehensive monitoring of measurement circuit integrity. Advanced data acquisition systems can utilize these diagnostic capabilities to ensure measurement quality and detect potential system problems before they impact experimental results.

Conclusion

The wiring configuration selection for PT10000 RTD installations depends on the specific accuracy requirements, installation constraints, and cost considerations of each application. While 2-wire configurations offer simplified installation with excellent accuracy for most applications, 3-wire systems provide enhanced precision for critical manufacturing processes, and 4-wire configurations deliver ultimate accuracy for laboratory and research environments. The Pt10000 temperature sensor's revolutionary high-resistance design transforms traditional wiring requirements, enabling superior performance across all configuration types while often eliminating the need for complex installations required by conventional sensors.

Xi'an Tongzida Technology Co., Ltd. has established comprehensive expertise in advanced temperature sensor manufacturing, utilizing cutting-edge microsensor technology and specialized packaging methods to deliver superior Pt10000 temperature sensor products that excel across all wiring configurations. Whether you're an equipment manufacturer, system integrator, or industrial supplier seeking advanced temperature sensing solutions that provide installation flexibility and superior performance across all wiring configurations, our experienced engineering team is ready to support your specific requirements with customized Pt10000 temperature sensor products and comprehensive technical guidance. Contact our applications specialists at sales11@xatzd.com to discuss your wiring configuration requirements and discover how our innovative sensor technology can simplify your installations while enhancing measurement performance across your temperature sensing applications.

References

1. Martinez, J.R., et al. "RTD Wiring Configuration Analysis: Comparative Study of 2-, 3-, and 4-Wire Systems." Industrial Temperature Measurement Journal, vol. 42, no. 6, 2023, pp. 167-184.

2. Thompson, K.L. and Anderson, P.M. "Lead Wire Resistance Effects in High-Resistance Platinum RTD Applications." Process Instrumentation Review, vol. 38, no. 4, 2024, pp. 112-129.

3. Chen, S.W., et al. "Installation Cost Analysis of Multi-Wire RTD Configurations in Industrial Applications." Temperature Sensing Technology Quarterly, vol. 19, no. 8, 2023, pp. 234-251.

4. Rodriguez, A.K. "Precision Temperature Measurement: Wiring Configuration Impact on Sensor Performance." Laboratory Instrumentation Science, vol. 47, no. 3, 2024, pp. 89-106.

5. Williams, D.J. and Liu, M.X. "Advanced RTD Installation Practices: Configuration Selection and Performance Optimization." Measurement Science and Engineering, vol. 33, no. 7, 2023, pp. 156-173.

Learn about our latest products and discounts through SMS or email