- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How does an RTD sensor work?

An RTD (Resistance Temperature Detector) sensor, such as the Pt100 Thin Film Sensor, operates on the principle of temperature-dependent electrical resistance. As temperature changes, the resistance of the platinum element within the sensor varies proportionally. The sensor's resistance increases with rising temperatures and decreases as temperatures fall. This precise relationship between temperature and resistance allows for accurate temperature measurements. RTD sensors typically utilize a Wheatstone bridge circuit or a constant current source to measure the resistance change, which is then converted into a corresponding temperature value using calibration data or standardized equations.

Understanding the Pt100 Thin Film Sensor Technology

Composition and Structure of Pt100 Thin Film Sensors

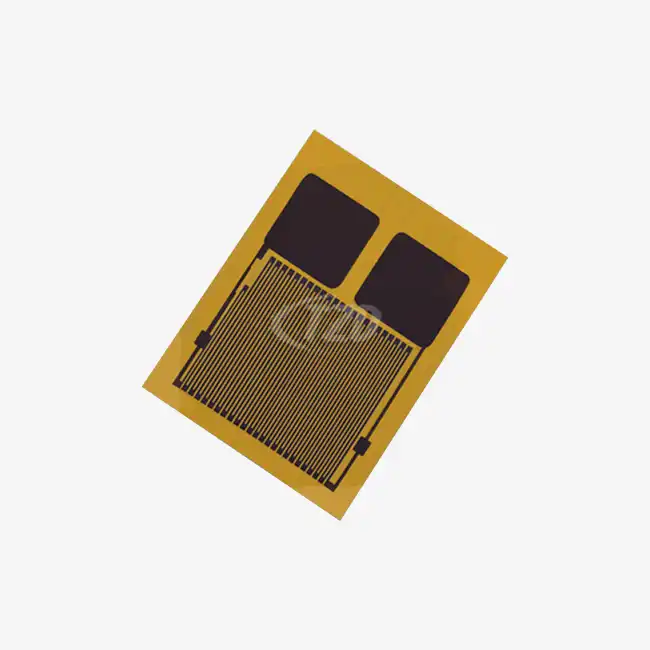

Pt100 Thin Film Sensors represent a cutting-edge development in temperature measurement technology. These sensors are fabricated using advanced thin-film deposition techniques, where a precise layer of platinum is applied to a ceramic substrate. The platinum film, typically measuring just a few micrometers in thickness, forms the sensing element of the RTD.

The structure of a Pt100 Thin Film Sensor is meticulously designed to optimize performance. The platinum film is patterned into a serpentine or meander shape, which maximizes the sensor's surface area while maintaining a compact overall size. This design enhances the sensor's sensitivity and responsiveness to temperature changes. The sensing element is then encapsulated within a protective layer to shield it from environmental factors and ensure long-term stability.

Advantages of Thin Film Technology in RTD Sensors

Thin film technology offers several advantages over traditional wire-wound RTD sensors. The precision manufacturing process allows for exceptional uniformity and repeatability in sensor characteristics. This results in improved accuracy and interchangeability between sensors, simplifying calibration and replacement procedures in industrial applications.

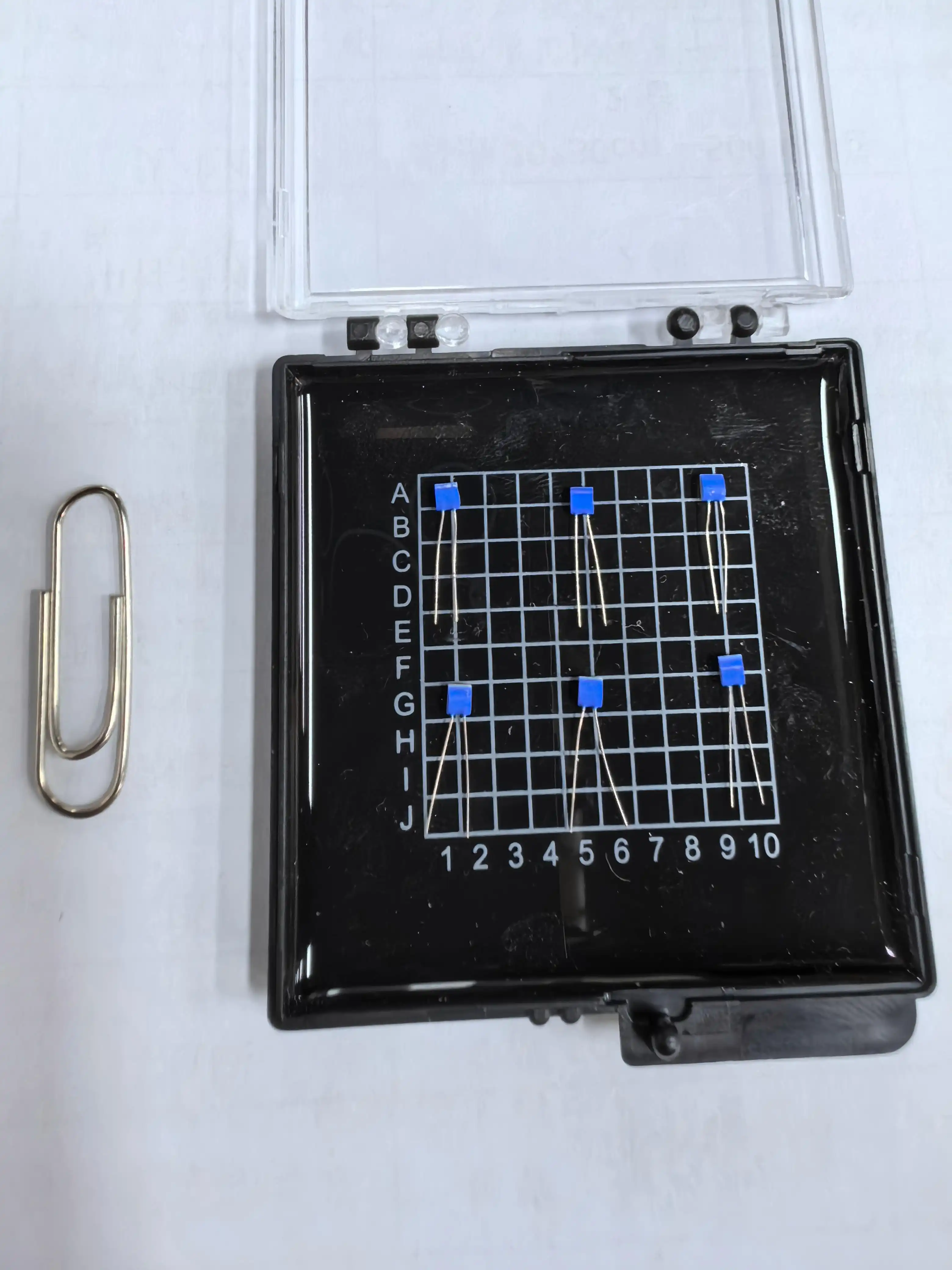

Moreover, the compact size of Pt100 Thin Film Sensors enables their integration into smaller devices and tighter spaces. For instance, sensors with dimensions as small as 3.2mm x 1.6mm x 0.7mm are available, making them ideal for miniaturized electronic systems and densely packed industrial equipment. The reduced thermal mass of thin film sensors also contributes to faster response times, enabling more dynamic temperature measurements in rapidly changing environments.

Temperature Coefficient and Measurement Range

A key parameter of Pt100 Thin Film Sensors is their temperature coefficient of resistance (TCR), which quantifies the sensor's sensitivity to temperature changes. High-quality sensors typically feature a TCR of 3850 ppm/°C, adhering to the IEC60751 standard. This standardization ensures consistency across different sensor manufacturers and simplifies integration into measurement systems.

The measurement range of Pt100 Thin Film Sensors is impressively wide, often spanning from -50°C to +200°C for standard models. However, specialized versions can extend this range further, with some high-performance sensors capable of measuring temperatures from -200°C to +850°C. This broad range makes Pt100 Thin Film Sensors versatile tools for diverse applications, from cryogenic processes to high-temperature industrial operations.

Applications and Implementation of Pt100 Thin Film Sensors

Industrial and Scientific Applications

Pt100 Thin Film Sensors find extensive use in various industrial and scientific applications due to their accuracy, stability, and reliability. In process industries, these sensors play a crucial role in monitoring and controlling temperatures in chemical reactors, distillation columns, and heat exchangers. Their rapid response time and high accuracy make them invaluable in pharmaceutical manufacturing, where precise temperature control is essential for product quality and safety.

In scientific research, Pt100 Thin Film Sensors are employed in laboratory equipment such as incubators, cryostats, and climate chambers. Their wide temperature range and excellent stability enable researchers to conduct experiments under tightly controlled thermal conditions. Additionally, these sensors are utilized in environmental monitoring systems, providing accurate temperature data for climate studies and weather forecasting.

Automotive and Aerospace Applications

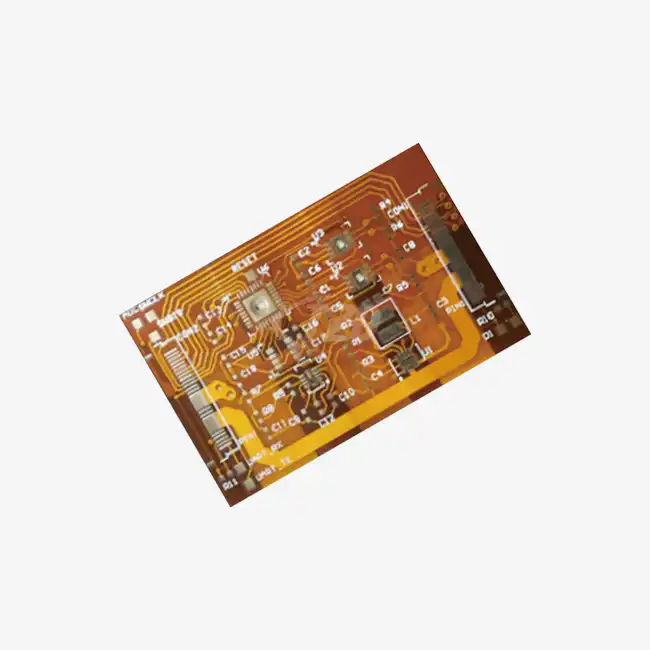

The automotive industry increasingly relies on Pt100 Thin Film Sensors for various temperature measurement tasks. These sensors are integrated into engine management systems to monitor coolant and oil temperatures, ensuring optimal engine performance and preventing overheating. In electric vehicles, thin film RTDs play a critical role in battery temperature monitoring, contributing to efficient thermal management and extended battery life.

Aerospace applications demand sensors that can withstand extreme conditions while maintaining high accuracy. Pt100 Thin Film Sensors meet these requirements, offering robust performance in aircraft engines, hydraulic systems, and environmental control systems. Their ability to operate reliably under high vibration (up to 40g) and impact (up to 100g) conditions makes them suitable for the rigorous demands of aerospace environments.

Medical and Healthcare Applications

In the medical field, Pt100 Thin Film Sensors contribute to the advancement of diagnostic and therapeutic devices. Their compact size and fast response time make them ideal for integration into medical equipment such as blood analyzers, PCR machines, and sterilization systems. These sensors enable precise temperature control in incubators for neonatal care and laboratory cell cultures, where even slight temperature variations can have significant consequences.

Thin film RTDs also find applications in non-invasive medical devices, such as infrared thermometers and thermal imaging systems. Their ability to provide accurate and rapid temperature measurements supports early detection of fever and other temperature-related health issues, enhancing patient care and public health monitoring capabilities.

Installation and Maintenance Considerations for Pt100 Thin Film Sensors

Proper Installation Techniques

Correct installation of Pt100 Thin Film Sensors is crucial for achieving optimal performance and longevity. When mounting these sensors, it's essential to ensure good thermal contact with the measured surface or medium. This often involves using thermally conductive compounds or adhesives to minimize thermal resistance between the sensor and the measurement point.

For surface temperature measurements, sensors should be securely attached to prevent displacement during operation. In fluid temperature measurements, proper immersion depth and flow conditions must be considered to avoid measurement errors due to stem conduction or self-heating effects. Additionally, care should be taken to protect the sensor leads and connections from mechanical stress and environmental factors that could compromise the sensor's integrity.

Soldering and Electrical Connection Best Practices

Pt100 Thin Film Sensors typically feature tin alloy terminals for electrical connections. When soldering these sensors, it's crucial to use appropriate techniques to prevent damage to the sensitive element. Reflow soldering or wave soldering methods are commonly employed, with high-temperature solder paste recommended for optimal results. The soldering temperature should be carefully controlled, typically within the range of 230-240°C, to ensure a reliable connection without compromising the sensor's calibration or structural integrity.

To maintain measurement accuracy, it's advisable to use a three-wire or four-wire connection scheme, especially for longer cable runs. These configurations help compensate for lead wire resistance, minimizing measurement errors. Shielded cables are often recommended to reduce electromagnetic interference, particularly in industrial environments with high electrical noise levels.

Calibration and Long-term Stability Considerations

While Pt100 Thin Film Sensors are known for their excellent stability, periodic calibration is recommended to ensure continued accuracy. The calibration frequency depends on the application's requirements and the sensor's operating conditions. Many high-quality sensors exhibit impressive long-term stability, with resistance drift as low as ±0.06% of R₀°C after 1000 hours of operation at 200°C.

To maintain sensor performance over time, it's important to operate the sensor within its specified temperature range and avoid exposure to contaminants or corrosive substances. Regular inspection of sensor connections and protective housings can help identify potential issues before they affect measurement accuracy. In critical applications, implementing redundant sensors or scheduled sensor rotation can provide additional assurance of measurement reliability.

Conclusion

Pt100 Thin Film Sensors represent a significant advancement in temperature measurement technology, offering high accuracy, fast response times, and excellent long-term stability. Their versatility and reliability make them invaluable tools across a wide range of industries and applications, from industrial process control to cutting-edge medical devices. As temperature measurement requirements continue to evolve, these sensors are well-positioned to meet the challenges of increasingly demanding applications.

For those seeking to integrate Pt100 Thin Film Sensors into their systems or explore custom sensor solutions, expert guidance is essential. Xi'an Tongzida Technology Co., Ltd. stands at the forefront of thin film sensor technology, offering a comprehensive range of products and expertise. To learn more about how our advanced sensor solutions can benefit your applications, please contact us at sales11@xatzd.com. Our team of specialists is ready to assist you in finding the optimal temperature measurement solution for your specific needs.

References

1. Lipták, B. G., & Venczel, K. (2016). Instrument and Automation Engineers' Handbook: Process Measurement and Analysis, Fifth Edition. CRC Press.

2. Michalski, L., Eckersdorf, K., Kucharski, J., & McGhee, J. (2001). Temperature Measurement. John Wiley & Sons.

3. Childs, P. R. N. (2001). Practical Temperature Measurement. Butterworth-Heinemann.

4. Dunn, W. C. (2018). Fundamentals of Industrial Instrumentation and Process Control. McGraw-Hill Education.

5. Baker, B. C. (2011). Precision Temperature-Sensing With RTD Circuits. Analog Dialogue, 45(2), 1-6.

Learn about our latest products and discounts through SMS or email