Grasping RTD Technology and Its Applications

Resistance Temperature Detectors (RTDs) are precision temperature sensors that utilize the principle of electrical resistance change in metals with temperature. Platinum is the most commonly used material for RTDs due to its stability, linearity, and wide temperature range. The Pt500 RTD chip, with its nominal resistance of 500 ohms at 0°C, represents a crucial component in this technology.

RTDs, including the Pt500 RTD chip, find applications across various industries. In industrial processes, they monitor and control temperatures in manufacturing equipment. The medical field relies on RTDs for precise temperature measurements in diagnostic tools and patient monitoring systems. Aerospace and automotive sectors utilize RTDs for engine temperature monitoring and environmental control systems. The versatility of Pt500 RTD chips makes them indispensable in these high-demand scenarios.

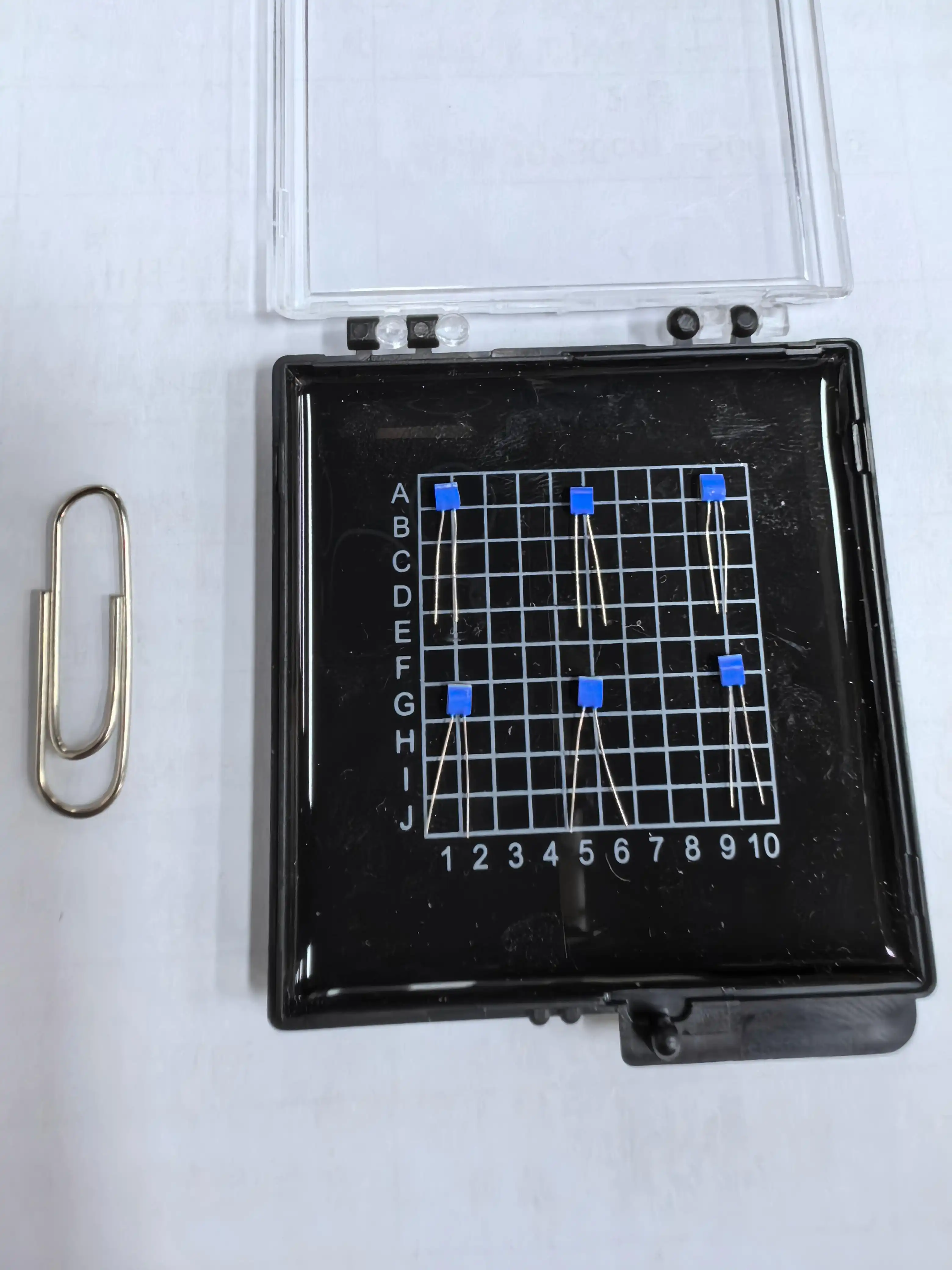

The thin film platinum resistance thermistor technology employed in modern Pt500 RTD chips offers several advantages. These chips boast compact dimensions, typically around 2.0mm x 2.3mm x 1.0mm, allowing for integration into space-constrained designs. The temperature coefficient of resistance (TCR) for these chips is usually 3850 ppm/°C, providing excellent sensitivity and accuracy across a wide temperature range.

Key Features of Modern Pt500 RTD Chips

Contemporary Pt500 RTD chips exhibit remarkable characteristics that set them apart in the field of temperature sensing. These chips often feature platinum-nickel wire leads, with options for silver-palladium, platinum, or pure silver, depending on the specific application requirements. The lead specifications typically include a length of 10 mm and a diameter of 0.2 mm, ensuring robust connections.

One of the standout features of high-quality Pt500 RTD chips is their exceptional long-term stability. Premium chips can maintain a resistance drift of ≤±0.04% of R₀ (0°C reference) after 1000 hours at 500°C. This stability ensures reliable measurements over extended periods, even in harsh industrial environments.

The response time of these chips is another crucial factor. In water flow conditions (V=0.4 m/s), top-tier Pt500 RTD chips can achieve a t₀.₅ of 0.05 s and a t₀.₉ of 0.15 s. For airflow conditions (V=2 m/s), the response times are t₀.₅ = 3 s and t₀.₉ = 10 s. This rapid response enables real-time temperature monitoring in dynamic systems.

Comparing Pt500 and Pt1000 RTD Chips

While both Pt500 and Pt1000 RTD chips are based on platinum resistance technology, they differ in their nominal resistance values and consequently, their performance characteristics. The Pt500 RTD chip, with its 500-ohm resistance at 0°C, offers a balance between sensitivity and power dissipation that makes it suitable for a wide range of applications.

The Pt1000 RTD chip, with its higher 1000-ohm resistance, provides increased sensitivity and potentially better resolution in temperature measurements. However, this comes at the cost of increased self-heating effects, which can impact measurement accuracy in certain scenarios. The Pt500 RTD chip, on the other hand, strikes a balance between sensitivity and self-heating, making it a versatile choice for many applications.

In terms of current requirements, Pt500 RTD chips typically operate with currents between 0.1–0.7 mA, which helps minimize self-heating effects. The self-heating coefficient of these chips is often around 0.4°C/mW at 0°C, ensuring minimal measurement errors due to the sensing current.

Advantages of Pt500 RTD Chips

Pt500 RTD chips offer several advantages that make them a popular choice in temperature sensing applications. Their lower resistance compared to Pt1000 chips results in reduced lead wire resistance effects, which can be particularly beneficial in applications with long cable runs. This characteristic makes Pt500 RTD chips well-suited for industrial environments where sensors may be located far from measurement equipment.

Another significant advantage of Pt500 RTD chips is their robustness. High-quality chips can withstand vibrations of ≥40g acceleration in the frequency range of 10–2000 Hz and shock resistance of ≥100g acceleration (8 ms half-sine wave). This durability makes them ideal for use in harsh industrial environments, automotive applications, and aerospace systems where mechanical stresses are common.

The insulation resistance of Pt500 RTD chips is also noteworthy. Typical values are 100 MΩ at 20°C and >2 MΩ at 500°C, ensuring electrical isolation and measurement accuracy across a wide temperature range. This characteristic is crucial for applications in high-temperature environments or where electrical noise might be a concern.

Considerations for Selecting the Right RTD Chip

Choosing between Pt500 and Pt1000 RTD chips requires careful consideration of several factors. The specific requirements of your application should guide your decision. For instance, if you need high resolution and are working with short lead wires, a Pt1000 chip might be preferable. However, for applications with longer lead wires or where self-heating effects are a concern, a Pt500 RTD chip could be the optimal choice.

The temperature range of your application is another crucial factor. High-quality Pt500 RTD chips can cover a wide temperature range, typically from -200°C to +850°C, making them suitable for diverse applications. The accuracy requirements of your system should also be considered. Premium Pt500 RTD chips can achieve accuracies of ± 0.01 Ω, which translates to excellent temperature resolution.

Environmental factors play a significant role in chip selection. If your application involves exposure to vibrations or mechanical shocks, the robust construction of Pt500 RTD chips, with their high vibration and shock resistance, could be advantageous. Additionally, consider the packaging requirements of your application. Many Pt500 RTD chips are available in vacuum plastic packaging, with other options available upon request.

Integration and System Design Considerations

When integrating RTD chips into your system, several design aspects need attention. The lead material and specifications of the Pt500 RTD chip should be compatible with your circuit design. The availability of options like platinum-nickel, silver-palladium, or pure silver leads allows for flexibility in system integration.

The operating current of the RTD chip is another critical factor. For Pt500 RTD chips, the typical range of 0.1–0.7 mA should be considered in your circuit design to minimize self-heating effects. The self-heating coefficient (often around 0.4°C/mW at 0°C for Pt500 chips) should be factored into your calculations for high-precision applications.

Lastly, consider the long-term stability requirements of your application. The exceptional stability of high-quality Pt500 RTD chips, with drift rates of ≤±0.04% after 1000 hours at 500°C, ensures reliable performance over extended periods. This characteristic is particularly valuable in industrial processes or scientific research where long-term measurement consistency is crucial.

Conclusion

The choice between Pt500 and Pt1000 RTD chips ultimately depends on the specific requirements of your application. While both offer excellent performance, the Pt500 RTD chip often emerges as a versatile and cost-effective solution for a wide range of temperature sensing needs. Its balance of sensitivity, self-heating characteristics, and robust construction make it suitable for diverse applications across industries.

As technology continues to advance, we can expect further improvements in RTD chip performance, potentially expanding the applications of these precision temperature sensors. Whether you opt for a Pt500 or Pt1000 RTD chip, ensuring you select a high-quality component from a reputable manufacturer is crucial for achieving accurate and reliable temperature measurements in your applications. For more information about our range of RTD chips and how they can meet your specific needs, please contact our team at sales11@xatzd.com.