- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

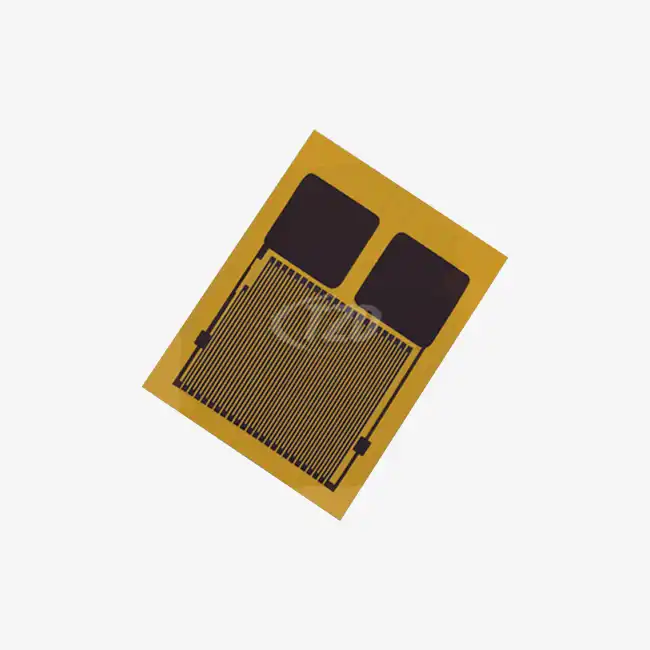

The core parameters of flexible thin film temperature sensors

1、 The core parameters of flexible thin film temperature sensors: understanding is necessary to choose correctly

1.1 Accuracy level: Grade A vs Grade B, the difference is not just the error

According to IEC 60584, the accuracy level of flexible thin film sensors directly affects the reliability of temperature measurement:

A-level (± 0.6 ° C): 0 ° C~100 ° C error ≤± 0.6 ° C, full range (-70 ° C~200 ° C) error ≤± 1.0 ° C, suitable for precision sensitive scenarios such as medical patches and precision instruments;

B-class (± 1.2 ° C): 0 ° C~100 ° C error ≤± 1.2 ° C, full range error ≤± 2.0 ° C, suitable for cost priority scenarios such as consumer electronics (such as headphones, wristbands) and general industrial monitoring.

Key differences: Grade A uses higher purity platinum film (99.99% vs Grade B 99.95%), TCR consistency is controlled at ± 5 ppm/° C (Grade B ± 10 ppm/° C), and long-term drift rate is 30% lower.

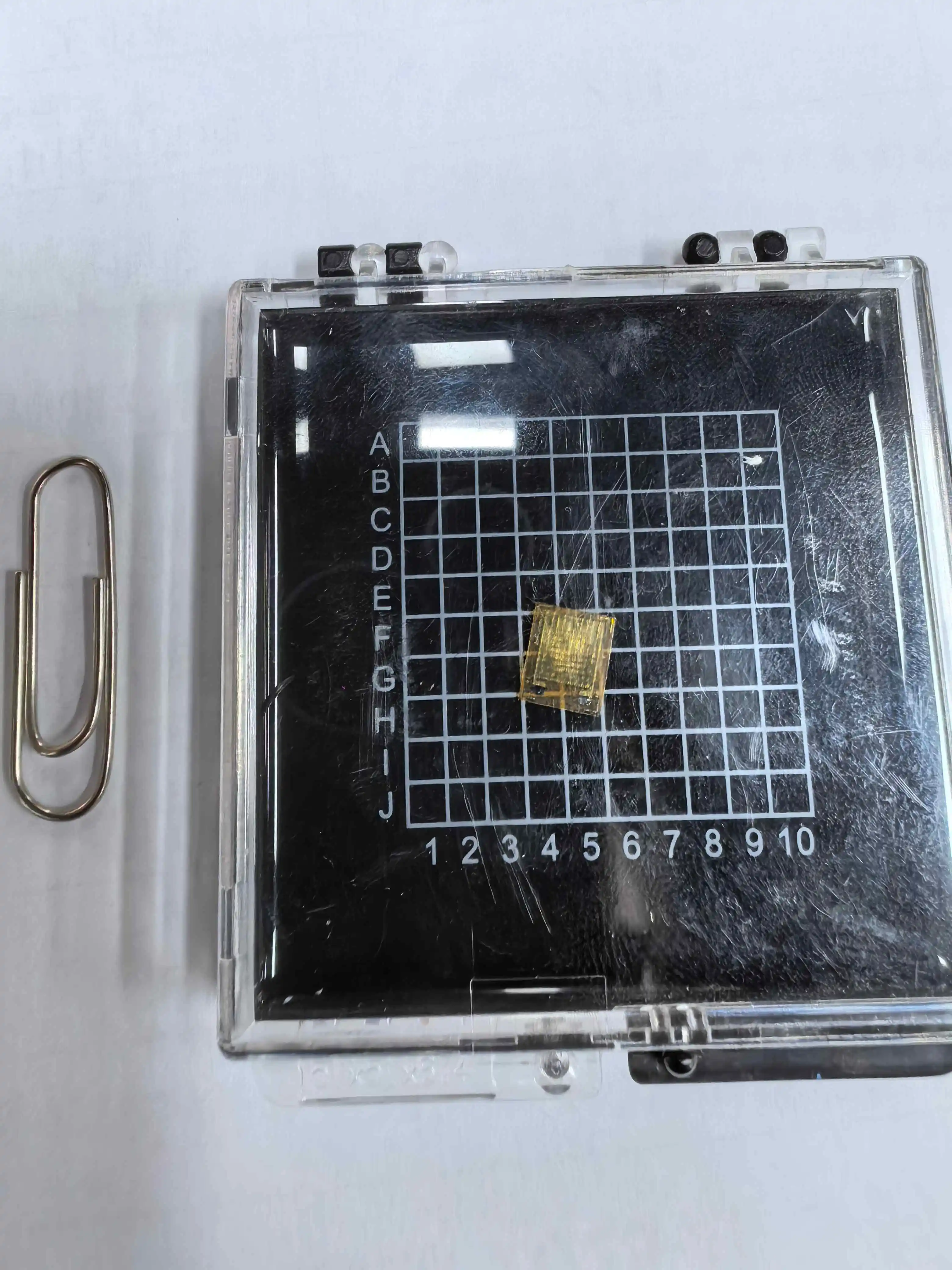

1.2 Size and Error: Why is ± 0.01mm an "invisible threshold"?

Our sensors are available in two standard sizes: 7x5x0.06mm (universal) and 3x4x0.06mm (miniature), and support ± 0.01mm size customization - this 0.01mm accuracy determines whether it can be embedded in millimeter level space:

3x4mm: Suitable for TWS headphone charging compartment gap, inner side of smartwatch crown;

7x5mm: covering the middle of the smart wristband and and the core area of the medical patch;

Customized size: Previously embedded the sensor into a "contact lens thermometer" (2x3mm) for customers, with an error of still ≤± 0.8 ° C (Class A).

2、 Scenario based selection: A-level/B-level+golden combination of size

2.1 Medical Health: Choose A-level, accuracy is the "lifeline"

Scenario: Continuous Glucose Monitoring (CGM) Patch, Postoperative Wound Thermostatic Patch;

Recommendation: A-class+3x4mm (miniaturized)+tin plated solder pads (anti-oxidation, suitable for long-term skin adhesion);

Case: A medical technology company used an A-grade 3x4mm sensor to create a "baby fever reducing patch" with a temperature measurement error of ± 0.5 ° C, resulting in a 90% increase in parent satisfaction.

2.2 Consumer Electronics: B-level is sufficient, cost savings of 30%

Scenario: TWS earphone case temperature monitoring, smart wristband motion temperature measurement;

Recommendation: B-class+7x5mm (universal type)+standard solder pads (suitable for batch SMT mounting);

Case: After switching to B-grade 7x5mm, a headphone manufacturer reduced the cost of a single sensor by 0.8 yuan and saved 120000 yuan in annual procurement costs.

2.3 Industrial micro monitoring: customized size+A-level, solving "space anxiety"

Scenario: Robot joint gap temperature measurement, local monitoring of drone battery pack;

Recommendation: A-level+customized size (such as 5x3mm)+tin plated solder pads (anti vibration);

Advantage: The ± 0.01mm size error ensures a "tight fit" and avoids data jumps caused by loose sensors.

3、 Actual test data: What is the difference in accuracy between Class A/Class B?

We conducted comparative testing in a 25 ° C constant temperature chamber (with a wire length of 10cm and tin plated solder pad connection):

Temperature point A-level measurement error B-level measurement error conclusion: 0 ° C+0.4 ° C+0.9 ° CA level low temperature segment has significant accuracy advantages of 37 ° C (human body)+0.3 ° C+0.8 ° C Medical scene must choose A-level 100 ° C+0.5 ° C+1.1 ° C Industrial high temperature monitoring A-level is more stable. Conclusion: Selection formula=scene accuracy requirements+spatial limitations

Select A-level: Medical skin patching, precision instruments, low-temperature (-70 ° C~50 ° C) scenarios;

Choose B-level: consumer electronics, general industrial monitoring, cost sensitive scenarios;

Size formula: Choose 3x4mm for micro spaces (<5mm ²), 7x5mm for regular spaces, and customize for special scenarios.

<u> The core value of flexible thin film temperature sensors</u>is to make "temperature measurement" no longer limited by "shape and size" - selecting the right parameters is necessary for the technology to be implemented.

FAQ: The 5 Most Concerned Questions for Engineers

Q: How much is A level more expensive than B level?

A: The unit price is 15% to 20% higher, but the long-term reliability return in medical/precision scenarios far exceeds the cost difference.

Q: Can the size error of ± 0.01mm be guaranteed?

A: Sure - we use laser cutting+visual inspection, and each sensor comes with a 'size inspection report'.

Q: How many times can tin plated solder pads withstand insertion and extraction?

A: ≥ 500 times (industry average of 200 times), suitable for R&D scenarios with frequent debugging.

CTA: Free access to selection reports

Click the consultation button to submit your "scene+accuracy+size" requirements. We will generate a free "Customized Solution for Flexible Thin Film Temperature Sensor" and give away the "SMT Mounting Guide for Micro Sensors"!

References

IEC 60584-1:2013 Thermocouples and Thermistors Standard;

Optimization Report on Temperature Measurement of Infant Fever Reduction Patch by a Medical Technology Company;

Consumer Electronics Association's White Paper on TWS Earphone Temperature Monitoring.

Xi'an Tongzeda Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, dedicated to providing high-performance temperature sensors for demanding industrial applications. We have comprehensive expertise in microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods to ensure excellent performance and reliability of thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including core sensitive chips, testing systems, and analysis software. Please contact our technical experts sales11@xatzd.com Discuss your specific thermistor requirements and learn how our advanced resistor temperature optimization and manufacturing capabilities can improve the performance and reliability of your temperature measurement system.

Learn about our latest products and discounts through SMS or email