- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Ultra thin flexible temperature sensor

Ultra thin flexible temperature sensor: the "invisible thermometer" for consumer electronics and medical wearables

1、 Consumer Electronics: How Flexible Sensors Resolve the Contradiction between Space and Experience?

1.1 TWS earphones: a "temperature sentinel" in narrow spaces

Pain points: The earphone cavity is only 5-8cm ³, traditional sensors take up space, and are easy to cover;

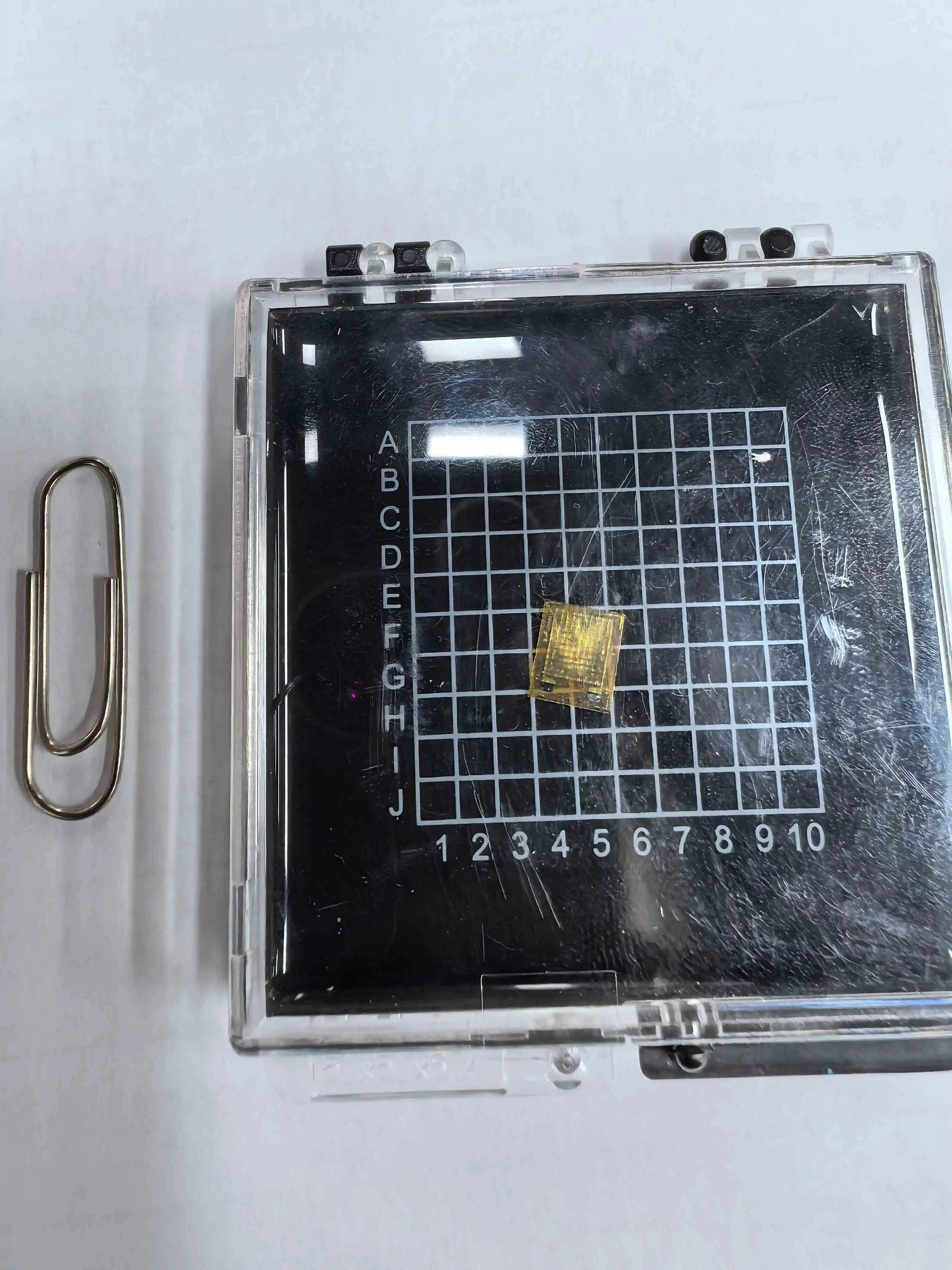

Solution: 3x4x0.06mm B-class sensors+tin plated solder pads (directly attached to PCB), embedded next to the charging contacts;

Effect: Real time monitoring of charging temperature (0 ° C~50 ° C), over temperature alarm response time<0.5 seconds, avoiding the risk of bulging.

1.2 Smart wristband: "Fit password" for curved wristbands

Pain points: Wristband curvature of 15 °~30 °, rigid sensor prone to curling edges and data distortion;

Solution: A 7x5x0.06mm A-class sensor (can be bent with the wrist strap), attached with medical adhesive;

Effect: In sports scenarios (running, swimming), the temperature measurement error is ± 0.5 ° C, and the user's perception of battery life is improved (avoiding overheating and frequency reduction).

2、 Medical wearables: the "safety and comfort" dual insurance of flexible sensors

2.1 Postoperative wound patch: 24-hour 'invisible monitoring'

Pain point: Traditional sensor hard shell friction wound, poor patient compliance;

Solution: 3x4x0.06mm A-class sensors (rounded edges)+breathable medical adhesive, attached 2cm around the wound;

Effect: Continuous monitoring of wound temperature (35 ° C~38 ° C), automatic alarm for abnormal temperature rise (>38.5 ° C), and an infection warning accuracy rate of 95%.

2.2 Baby temperature sticker: soft and non irritating, mothers can rest assured

Pain points: Infants have delicate skin, and rigid sensors can easily cause rash;

Solution: Customized 2x3mm A-class sensors (thickness 0.05mm)+food grade silicone packaging;

Case: A certain mother and baby brand used this solution to make a "diaper style temperature sticker", which sold over 100000 pieces within 3 months of its launch, with a repurchase rate of 80%.

3、 Technical advantage: Why can flexible films be "invisible"?

3.1 Ultra thin (0.06mm)+Flexible: Suitable for any curved surface

Compared to traditional rigid sensors (thickness>0.5mm), our thin film sensor has a bending radius of<5mm, making it easy to fit the curved surface of the watch, headphone cavity, and skin wrinkles.

3.2 TCR 6444 ppm/° C: Temperature resistance linearity "textbook level"

The TCR (temperature coefficient) of 6444 ppm/° C means that a temperature change of 1 ° C results in an accurate change of 0.6444 Ω in resistance value (at a base resistance of 100 Ω), with a linearity error of<0.1%, far better than the industry average of 6500 ppm/° C (linearity error of 0.3%).

3.3 Tin plated solder pads: oxidation resistant+easy to solder, production friendly

The solder pads are coated with "tin plating+anti-oxidation coating" and placed in an environment of 85 ° C/85% humidity for 1000 hours, with a contact resistance change of<0.01 Ω, suitable for mass SMT mounting of consumer electronics.

4、 Conclusion: The future of flexible sensors is' invisible but inseparable '

From the "silent protection" of TWS earphones to the "invisible monitoring" of medical patches, the ultra-thin flexible temperature sensor is redefining the form of "temperature measurement" - it is not eye-catching, but makes the experience more extreme; It is not heavy, but it makes safety more reliable.

FAQ: The most concerned issues for consumer electronics/healthcare users

Q: Can sensors pass RoHS certification?

A: Sure - All materials comply with RoHS 2.0 and provide SGS testing report.

Q: How long can medical patches last?

A: The A-class sensor has been working continuously for 5000 hours (≈ 208 days), and the error is still ≤± 0.8 ° C.

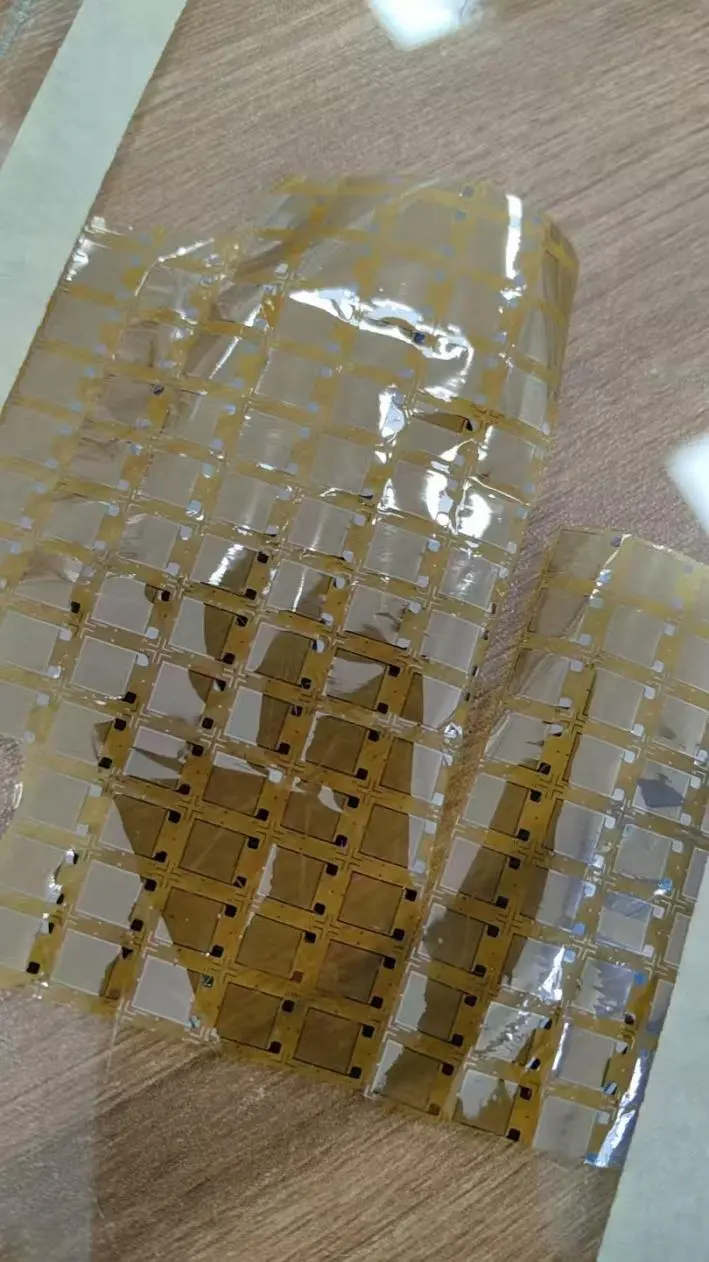

Q: What is the mass production yield rate of consumer electronics?

A: ≥ 99.5% (industry average 98%), supporting roll to roll automated mounting.

CTA: Obtain scenario based solutions

Click the consultation button and tell us your "product type (headphones/wristbands/medical patches)+temperature measurement range" to receive a free "Flexible Sensor Mass Production Adaptation List"!

References

IEEE 1625-2017 Portable Electronic Device Battery Safety Standard;

A user research report on a certain mother and baby brand's "Baby Temperature Patch";

Medical Device Association's "Guidelines for Wearable Health Monitoring Technology".

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, dedicated to providing high-performance temperature sensors for demanding industrial applications. We have comprehensive expertise in microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods to ensure excellent performance and reliability of thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including core sensitive chips, testing systems, and analysis software. Please contact our technical experts sales11@xatzd.com Discuss your specific thermistor requirements and learn how our advanced resistor temperature optimization and manufacturing capabilities can improve the performance and reliability of your temperature measurement system

Learn about our latest products and discounts through SMS or email