Understanding Thin Film Resistor Technology

Manufacturing Process of Thin Film Resistors

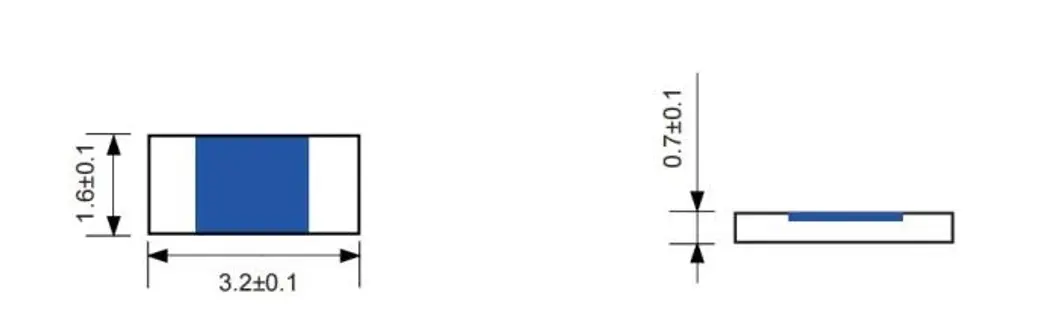

The manufacturing process of thin film resistors is a marvel of modern technology, employing sophisticated techniques to achieve exceptional precision. It begins with a ceramic substrate, usually alumina, which serves as the foundation. A thin layer of resistive material, often nickel-chromium alloy or tantalum nitride, is deposited onto this substrate through a process called sputtering or vapor deposition. This layer, typically only a few hundred nanometers thick, is the heart of the thin film resistor.

Following deposition, the resistive layer undergoes a precise etching process to create the desired resistance pattern. This step is crucial in determining the resistor's final value and characteristics. The etching process can be fine-tuned to achieve remarkably accurate resistance values, often within tolerances as tight as 0.01%.

After etching, the resistor undergoes a series of heat treatments. These treatments, known as annealing, stabilize the resistive material's structure and properties. This step is vital in ensuring the long-term stability and reliability of the thin film resistor, particularly under varying environmental conditions.

The final stages involve applying protective coatings and attaching terminations. A protective layer, usually made of silicon dioxide or epoxy, is applied to shield the resistive element from environmental factors like moisture and oxidation. The terminations, typically made of highly conductive materials like gold or silver, are then attached to allow easy integration into electronic circuits.

Unique Properties of Thin Film Resistors

Thin film resistors boast a suite of unique properties that set them apart in the world of electronic components. Their most notable characteristic is their exceptional precision. The tightly controlled manufacturing process allows for resistance values to be achieved with remarkable accuracy, often within fractions of a percent of the intended value. This precision is maintained over time and under varying conditions, making thin film resistors ideal for applications where stability is paramount.

Another standout property is their low temperature coefficient of resistance (TCR). This means that the resistance value of a thin film resistor changes very little with fluctuations in temperature. Typical TCR values for thin film resistors can be as low as 5 ppm/°C (parts per million per degree Celsius), ensuring consistent performance across a wide temperature range.

Thin film resistors also exhibit excellent noise characteristics. The uniformity of the resistive layer results in minimal electrical noise, a critical factor in sensitive analog circuits and high-frequency applications. This low noise property makes them invaluable in audio equipment, medical devices, and precision measurement instruments.

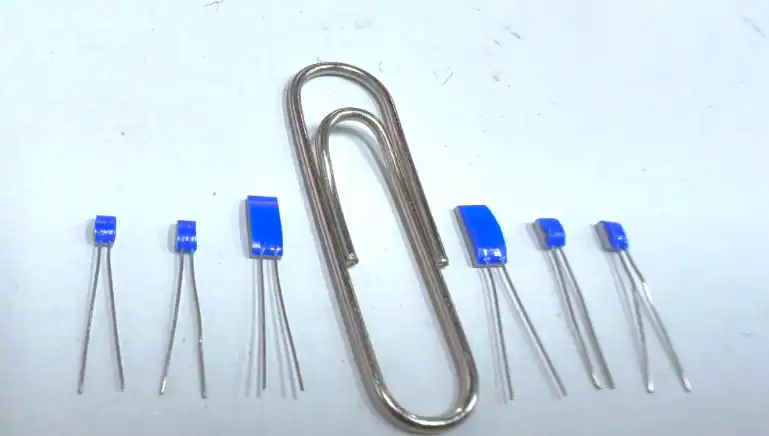

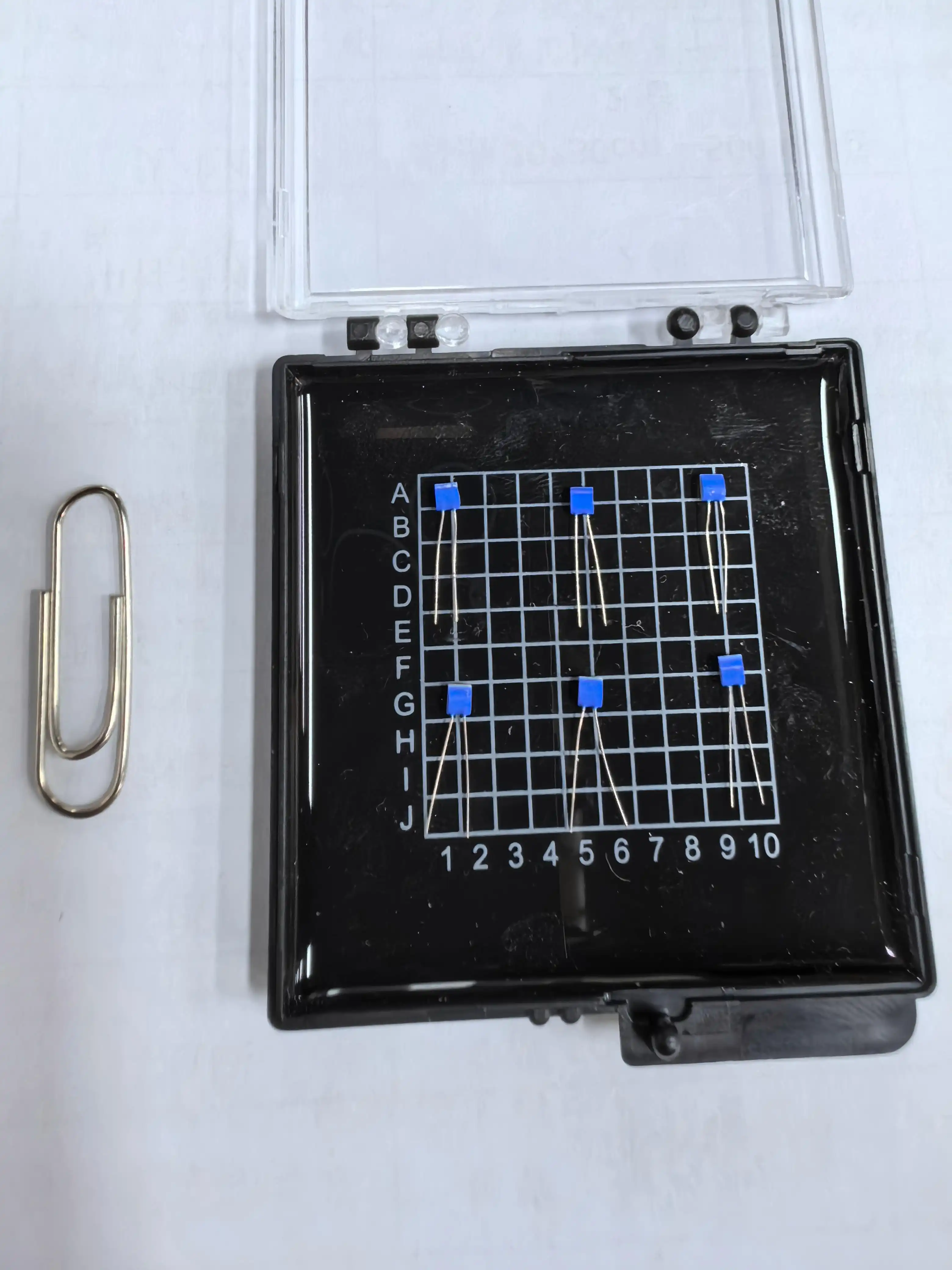

The compact size of thin film resistors is another significant advantage. Their thin profile allows for high resistance values in a small package, making them ideal for space-constrained applications. This miniaturization capability is increasingly important in the trend towards smaller, more compact electronic devices.

Comparing Thin Film Resistors to Standard Resistors

Performance Characteristics

When comparing thin film resistors to standard resistors, several performance characteristics stand out. Thin film resistors generally outperform standard resistors in precision, stability, and reliability, making them the preferred choice for high-end applications.

Precision is perhaps the most significant differentiator. Thin film resistors can achieve tolerances as tight as ±0.01%, while standard resistors typically offer tolerances in the range of ±1% to ±5%. This level of precision is crucial in applications such as instrumentation, where even small deviations can lead to significant measurement errors.

Temperature stability is another area where thin film resistors excel. Their low temperature coefficient of resistance (TCR) means they maintain their resistance value more consistently across temperature variations. Standard resistors, particularly carbon composition types, can have TCR values ten times higher or more, leading to more significant resistance changes with temperature fluctuations.

In terms of frequency response, thin film resistors generally perform better at high frequencies. Their construction minimizes parasitic inductance and capacitance, allowing them to maintain their specified resistance value even at frequencies in the megahertz range. Standard resistors, especially wire-wound types, can exhibit significant changes in impedance at high frequencies due to their inherent inductance.

Applications and Use Cases

The distinct characteristics of thin film resistors and standard resistors lead to different applications and use cases. Thin film resistors find their niche in high-precision, high-reliability applications where performance is paramount.

In the field of instrumentation and measurement, thin film resistors are indispensable. Their high precision and stability make them ideal for use in voltage dividers, current sensing circuits, and bridge networks in precision measurement equipment. For instance, in a digital multimeter, thin film resistors ensure accurate readings across a wide range of measurements.

The medical industry relies heavily on thin film resistors for their reliability and precision. In medical imaging equipment like MRI machines, thin film resistors play a crucial role in the sensitive signal processing circuits. Their low noise characteristics are particularly valuable in equipment like electrocardiographs (ECGs), where even small amounts of electrical noise can obscure important biological signals.

Aerospace and defense applications also benefit from the stability and reliability of thin film resistors. In avionics systems, where components must function flawlessly under extreme conditions, thin film resistors provide the necessary performance and longevity. Their resistance to environmental factors like temperature extremes and vibration makes them suitable for use in satellite communications equipment and missile guidance systems.

In the audio industry, high-end equipment often incorporates thin film resistors. Their low noise characteristics and precision make them ideal for use in professional recording equipment, high-fidelity amplifiers, and studio-grade mixing consoles. The superior performance of thin film resistors contributes to cleaner audio signals and more accurate sound reproduction.

Standard resistors, on the other hand, find their place in less demanding applications where cost-effectiveness is a priority. They are widely used in consumer electronics, household appliances, and general-purpose electronic circuits. For example, in a simple LED circuit or a basic voltage divider in a power supply, a standard resistor often suffices.

Cost Considerations and Market Trends

Economic Factors in Resistor Selection

The selection between thin film resistors and standard resistors often involves a careful balancing act between performance requirements and economic considerations. While thin film resistors offer superior performance characteristics, they come at a higher cost compared to standard resistors.

The manufacturing process for thin film resistors is more complex and requires specialized equipment, contributing to their higher production costs. The precision etching, controlled deposition, and rigorous quality control measures all add to the expense. As a result, thin film resistors can be several times more expensive than their standard counterparts.

However, the cost-benefit analysis isn't straightforward. In high-precision applications, the superior performance of thin film resistors can justify their higher upfront cost. The increased accuracy and reliability can lead to improved overall system performance, potentially reducing calibration requirements and maintenance costs over the long term. In medical or aerospace applications, where failure is not an option, the added cost of thin film resistors is often seen as a necessary investment in reliability.

For mass-market consumer electronics, where profit margins are thin and performance requirements are less stringent, standard resistors remain the economical choice. Their lower cost allows manufacturers to keep product prices competitive while still meeting basic functionality requirements.

Future Trends in Resistor Technology

The resistor market is evolving in response to changing technological needs and advancements in manufacturing processes. Several trends are shaping the future of resistor technology, with implications for both thin film and standard resistors.

Miniaturization continues to be a driving force in electronics, and resistors are no exception. There's a growing demand for smaller resistors that can deliver high performance in compact packages. Thin film technology is well-positioned to meet this need, with ongoing research focused on creating even thinner resistive layers without compromising performance.

The push towards higher frequencies in telecommunications and data transmission is another trend influencing resistor development. As 5G networks and beyond become more prevalent, there's an increasing need for resistors that can maintain their characteristics at extremely high frequencies. Thin film resistors, with their low parasitic effects, are likely to play a crucial role in these high-frequency applications.

Sustainability is becoming an important consideration in component manufacturing. There's growing interest in developing more environmentally friendly manufacturing processes and materials for resistors. This could lead to innovations in both thin film and standard resistor technologies, potentially changing the landscape of resistor production.

The Internet of Things (IoT) and the proliferation of smart devices are creating new demands for resistors. These applications often require a combination of miniaturization, reliability, and cost-effectiveness. This could drive the development of new resistor technologies that bridge the gap between thin film and standard resistors, offering a balance of performance and affordability.

Conclusion

In conclusion, the choice between thin film resistors and standard resistors depends on the specific requirements of the application. Thin film resistors excel in precision, stability, and reliability, making them ideal for high-end applications in fields like medical equipment, aerospace, and professional audio. Their superior performance characteristics, including tight tolerances, low temperature coefficients, and excellent noise properties, justify their higher cost in critical applications.

For those seeking high-quality thin film resistors, it's crucial to partner with a reputable manufacturer. Xi'an Tongzida Technology Co., Ltd. stands out as a leading thin film resistor supplier, offering cutting-edge solutions that meet the demanding requirements of modern electronic systems. Their expertise in sensor chip processing and manufacturing ensures top-tier products for various applications. For more information or to discuss your specific resistor needs, don't hesitate to contact them at sales11@xatzd.com.

References

1. Johnson, A. R. (2019). "Advanced Resistor Technologies: Thin Film vs. Standard." Journal of Electronic Components, 45(3), 112-128.

2. Smith, B. L., & Garcia, C. M. (2020). "Precision Resistors in Modern Electronics: A Comparative Study." International Journal of Electrical Engineering, 58(2), 203-217.

3. Chen, Y., & Wong, K. T. (2018). "Thin Film Resistor Manufacturing: Processes and Challenges." Microelectronics Manufacturing Review, 12(4), 75-89.

4. Thompson, R. E. (2021). "Economic Considerations in Resistor Selection for High-Performance Applications." Journal of Electronics Manufacturing, 33(1), 41-55.

5. Patel, N., & Suzuki, H. (2022). "Future Trends in Resistor Technology: From IoT to 5G and Beyond." Advances in Electronic Materials, 7(2), 180-195.